An ALL-PRO Addition for Concrete Works

Colorado-based company upgrades their production capabilities to compete for larger projects while still being mobile enough for the smaller jobs

Highlights

| Country / Region | USA |

|---|---|

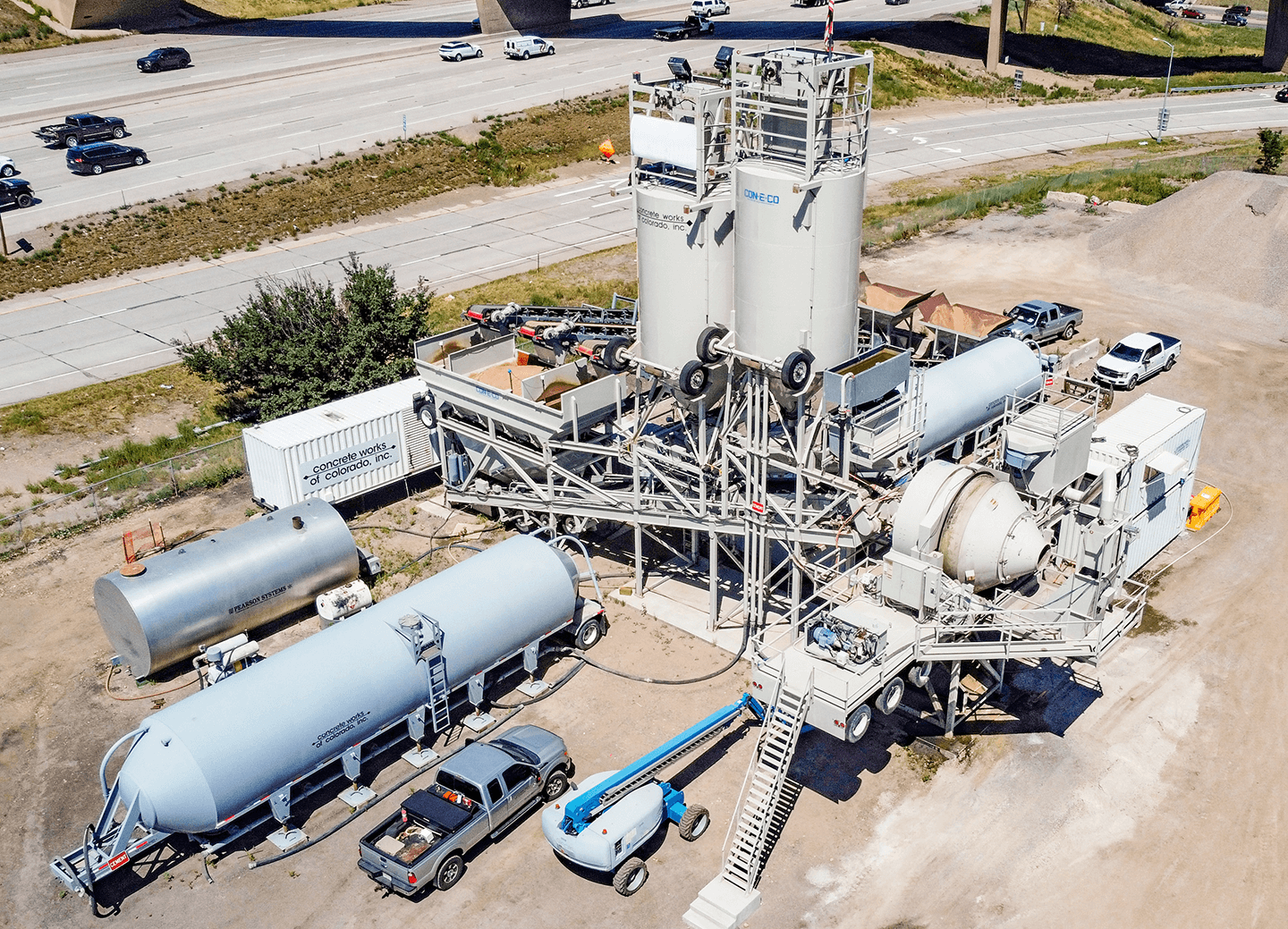

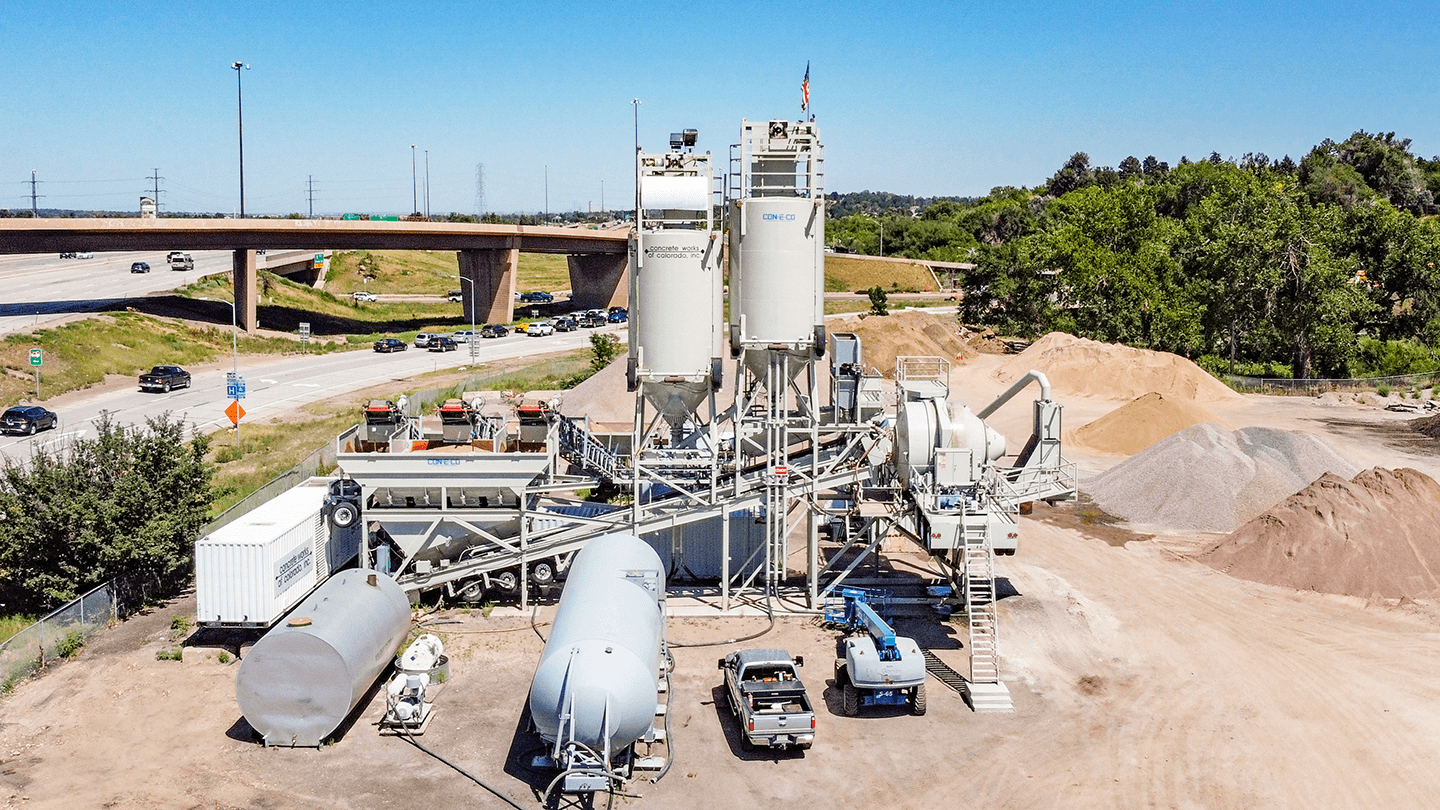

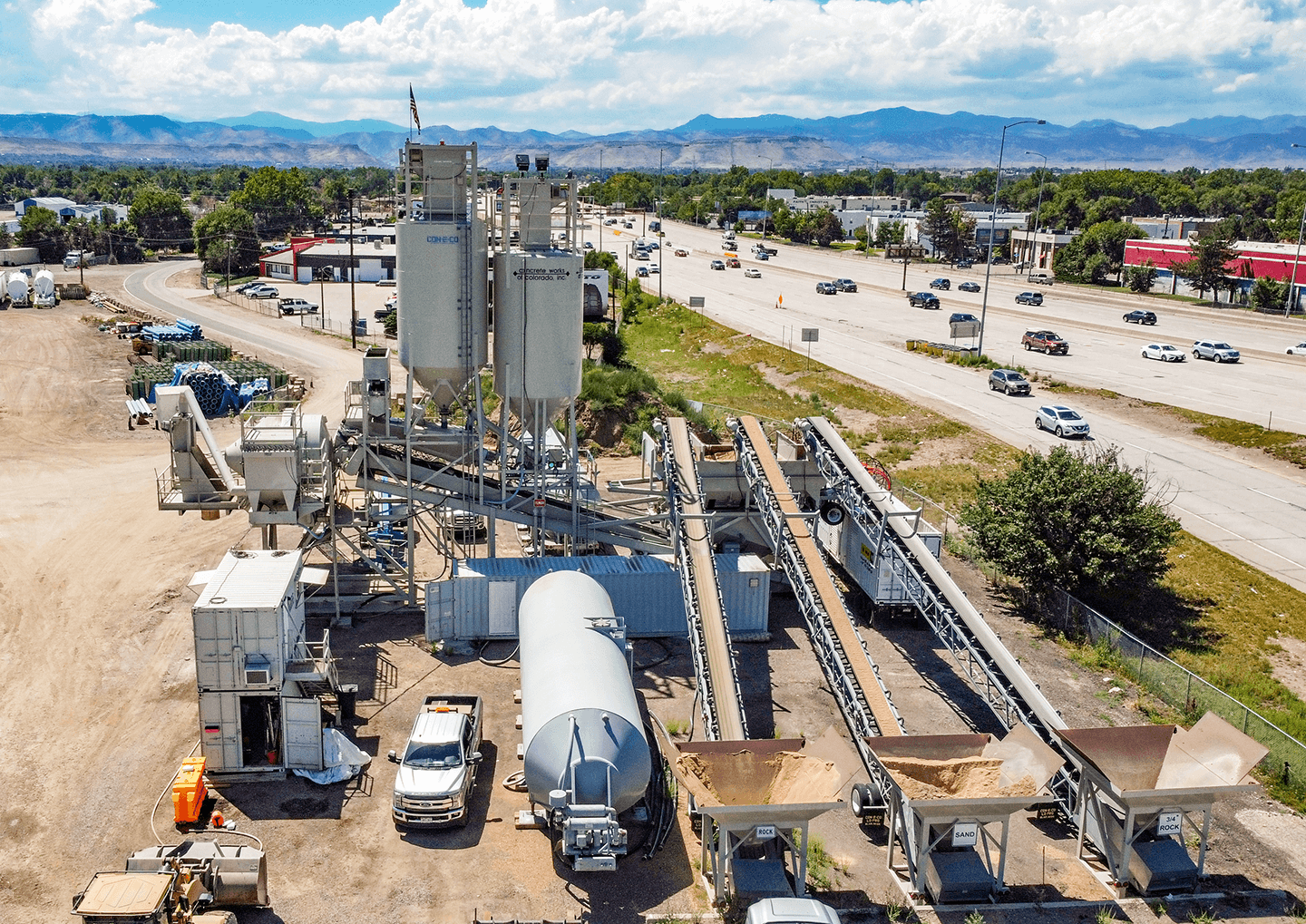

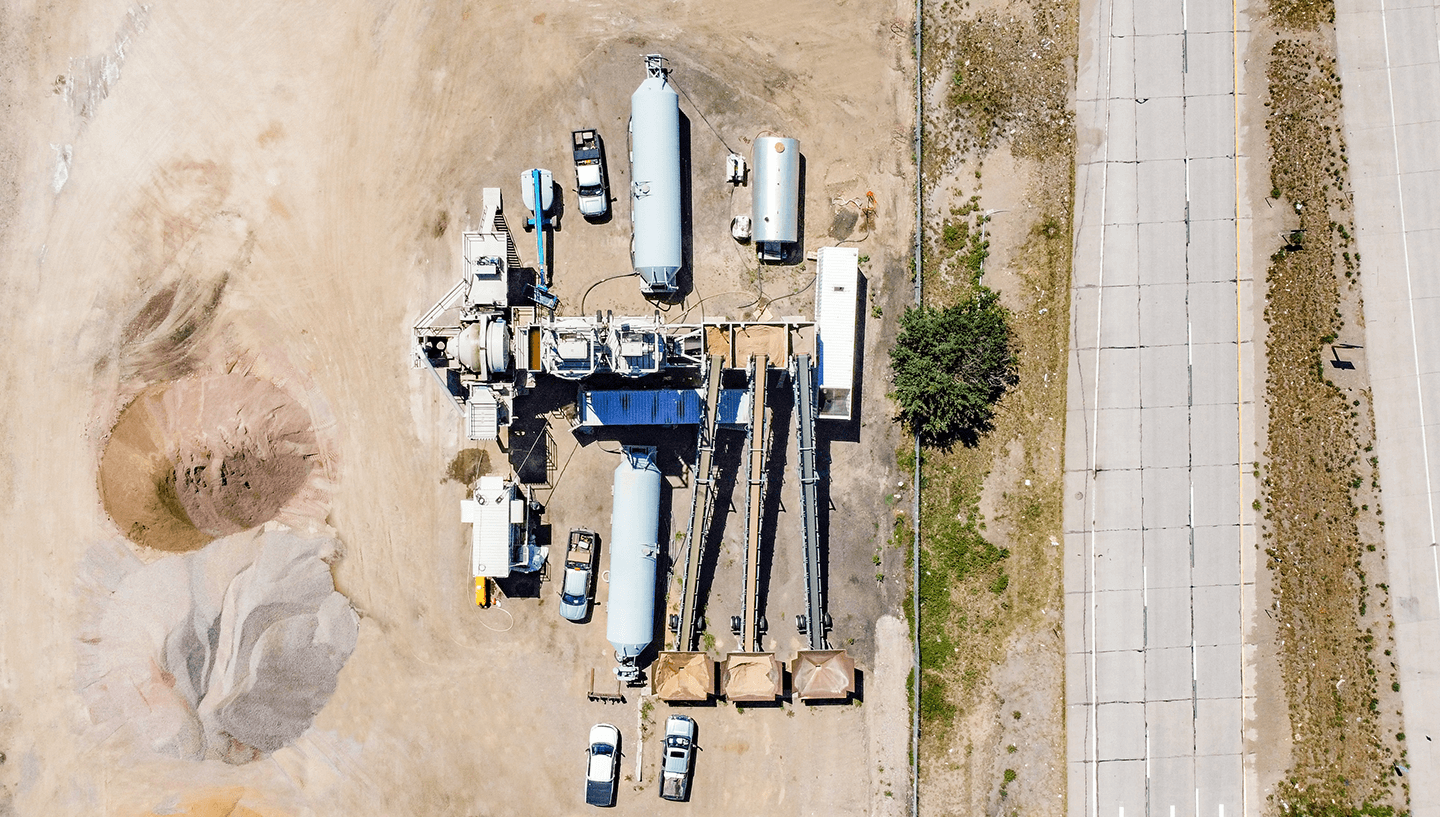

| Installation Site | Wheat Ridge, Colorado, USA |

| End User | Concrete Works of Colorado |

| Dealer | Faris Machinery |

| Application | Concrete Production |

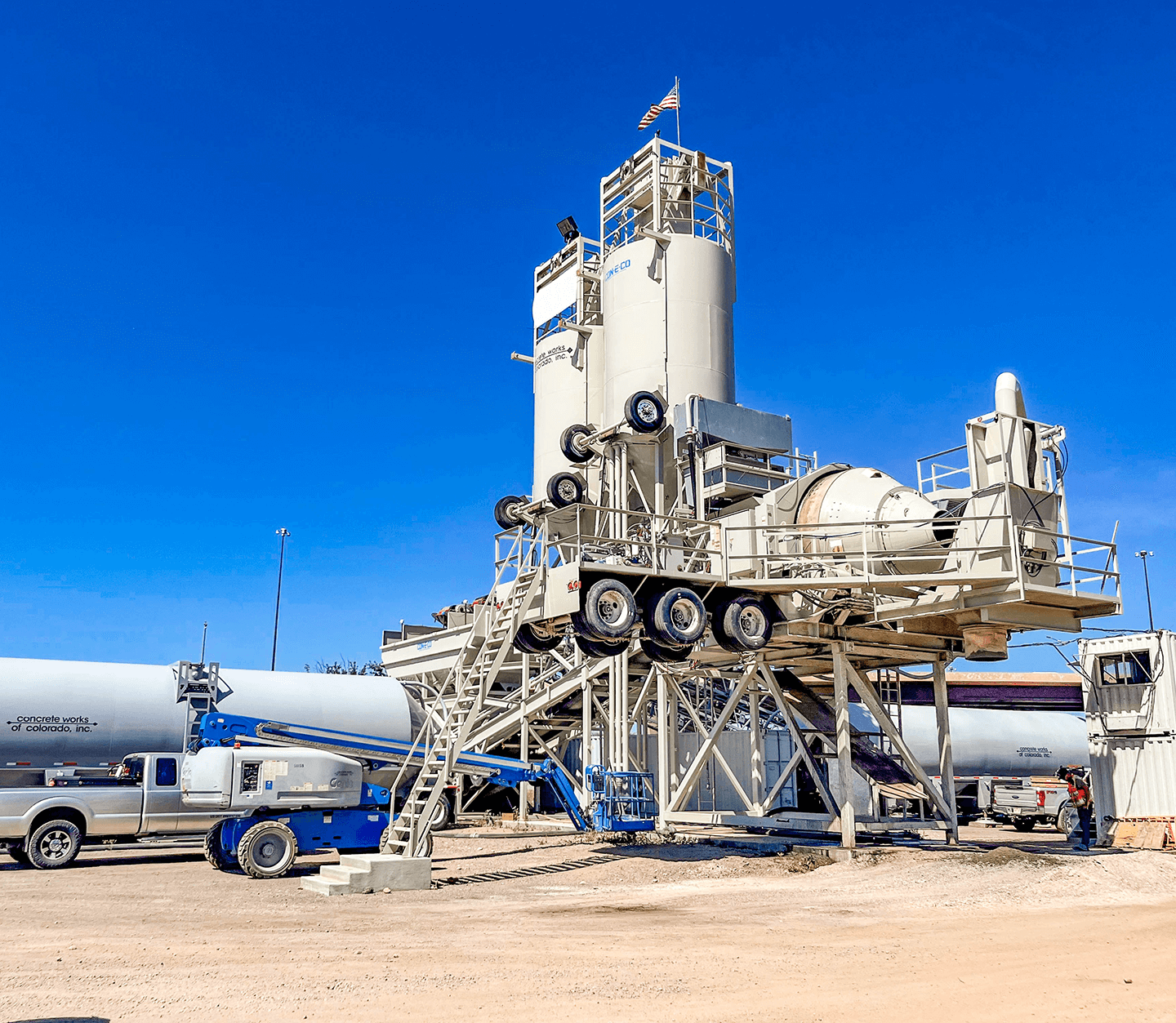

| Plant Type | CON-E-CO ALL-PRO |

Products

Concrete Works is a “small company doing big things.” Based in Lafayette, CO, the business specializes in municipal jobs, airport construction and wastewater/pipeline work. They recently won a bid to complete massive upgrades to a heavily trafficked area in Wheat Ridge, CO and knew they needed more production capacity to get it done.

The City of Wheat Ridge is an area of urban growth and Wadsworth is important to the movement of people in the community. Concrete Works was hired to revitalize the 1-½ mile section of roadway, excavating 10,000 cu.yds. approaching Interstate-70 embankments for a retaining wall. This would allow the company to widen the current roadway with full reconstruction from a 4-lane width roadway into a 6-lane width, including continuous flow intersections.

The work, which started in October of 2021, is ongoing and needs to be completed while maintaining two lanes of travel in each direction through unique phasing concepts. Concrete Works is completing the project in partnership with the City of Wheat Ridge and the Colorado Department of Transportation (CDOT).

“Concrete Works was basically hired to rebuild everything,” Jake Jacobson, Batch Plant Manager at Concrete Works says. “This road hasn’t really been upgraded in over 50 years so, in addition to widening capacity in each direction, we’re installing new water, new sanitary, new storm drains, new communication lines, and bringing it up to ADA compliance. We’re adding mobility for pedestrians and bicycles as well.”

The company is also installing continuous flow intersections to help improve traffic flow throughout the growing area.

On this project, Concrete Works has installed roughly 20,000 cu. yds. of roadway material and close to another 5,000 cu.yds. for the curb and gutter and sidewalks that have been installed on the project as well.

Performance & Portability

That type of capacity is just one reason why Concrete Works relies on Astec’s CON-E-CO Concrete Batch Plants to help them complete their growing list of municipal projects.

“We tend to take on a lot of the more challenging mid-range projects that bigger companies can’t complete because they don’t have the bigger equipment that doesn’t fit the job.” Jacobson says. “We’re a small company doing big things and we want to be versatile with the services we can provide our customers and having the right equipment is a big part of being able to do that.”

Concrete Works chooses Astec’s CON-E-CO Concrete Plants due to their reliability, smaller footprint, ease of transportation and quick set up times.

“We’ve had a lot of success with our CON-E-CO plants,” Jacobson says. “We purchased a LO-PRO Central Mix Plant for an airport project back in 2007 and bought a new ALL-PRO® SUPER in 2015 for the Department of Defense (DOD) Airport Base in Denver.”

The company had a project where their LO-PRO was tied up and purchased an ALL-PRO SUPER for use on jobsites like the one in Wheat Ridge. This project specifically needed a plant that could be set up in a confined metro area. Concrete Works also needed to be sure the plant design could accommodate the space and the trucking pattern for the project.

The ALL-PRO’s single, unitized, all welded structure also allows the entire plant to be set on a monolithic slab without large outside foundations. Plus the dust control system is mounted above the cement batcher and eliminates the need for an additional foundation or ground clutter. The ALL-PRO series also comes factory pre-wired and pre-plumbed, so Concrete Works was ready to produce concrete more quickly for the project.

“The CON-E-CO plants allow us to be more mobile so we can take on the smaller municipal jobs, while also giving us the capacity to produce enough mix to take bigger jobs as well,” Jacobson says. “The central mix plants allow us to haul our concrete to the paver.”

And the plants also keep up with the changing tight specifications Concrete Works sees on the DOT and DOD projects.

“The DOD is very specific in their criteria and we’ve never had an issue with meeting their requirements,” Jacobson adds.

Valued Partnerships

Many companies know that having the right partners to not only help them grow, but to be there when they need them, is key to being successful. Concrete Works has been in business over 45 years and values loyalty and dependability in all they do. They found both with their CON-E-CO dealer, Faris Machinery, who helped with this purchase.

“We’ve had good relationships with our CON-E-CO dealer over the years and wanted to remain loyal to them,” Jacobson says. “Faris represents a good and reliable product in these plants and we’ve been incredibly pleased with the service we’ve been given.

David Barthel, Key Account Manager at Faris agrees.

“Astec has been very involved in CON-E-CO’s dealer network,” Barthel says. “They are open to our feedback as well as working with customers to improve the product and the experience to ensure everyone’s success.”

As Concrete Works continues to expand, Jacobson says their plans will include purchasing another CON-E-CO to serve their customers and keep up with their success.

photo credit: Jason Barthel