Customer Needs Come First for Astec Construction Department

The entire Astec Construction team works diligently to provide a seamless plant installation process from start to finish

The purchase of an asphalt plant is a huge investment. You take extensive time to research what you need, you talk to other contractors, you talk to manufacturers and you ultimately talk to someone in sales to make a purchase.

If the company you’re working with is a good partner, that’s not the end of the conversation, but the beginning.

The Service and Construction Team at Astec is involved in every part of a new plant installation. From quote to training and beyond, their team of experts have over 1,000 years of experience to help the process go smoothly and each customer is vital to that.

“We strive to be the preferred construction and service provider to our customers,” Daniel Francisco, Vice‑President of Service and Construction at Astec, Inc. says. “We're continually broadening our construction and service offerings to be a true value for them. We know that if we take care of our customers, they're going to take care of us. That's the way we try to approach what we do every day.”

Confidence from Start to Finish

Making sure the customer is taken care of starts at the very beginning with the quoting process. The Astec Construction Department listens to the unique install needs of each customer and builds their quote around that conversation.

“We used to charge a percentage of the plant price for the plant install, but decided that wasn’t serving our customers the best way,” Francisco says. “Now we are in constant communication with our customers and completely transparent with our quoting process. If our customers don’t require the Astec team to complete certain portions of the install, they can take that on themselves. We customize each quote to meet their exact needs.”

From there, the team builds a construction pack and a site foreman is assigned to the installation.

“The documents in the construction pack contain all of the site drawings, all the side elevations, customer contact information, special safety protocols that may be required by the customer and more,” Francisco says. “Our construction foreman and structural technicians use this packet when they step onto the site to provide our customer’s confidence that we have all of the things we need to be able to get their job done effectively and efficiently.”

Once the parts are built and shipped, the site foreman and construction crew arrive at the plant location a few days before the parts arrive. On the back end, the crew is reviewing the equipment list again and ensuring they have everything they need to successfully complete the install. They review the plant layout site drawings in the construction pack one more time to determine if any additional manpower, tools, or larger cranes are needed.

“The site foreman supervises each site they are assigned to and they take that very seriously,” Francisco says. “The site foreman will be in constant communication with not only the customer, but the construction management team. The site foreman has direct communication to key departments at our manufacturing sites. That includes our shipping, engineering, manufacturing, parts, sales and service.

“This is the One Astec approach that gives the site foreman the ability to provide a seamless process for the customer,” Francisco continues. “We want our customers to know they have one point of contact and once that construction foreman gets on the jobsite, he handles all of their needs and questions. The foreman that's on the site, he is that partner to that customer and will get all their questions answered.”

On Site & Top of Mind

Once the plant is installed by the construction team, a process that can take a team of five anywhere from two to eight weeks depending on plant type and size, support from the Astec team is far from over.

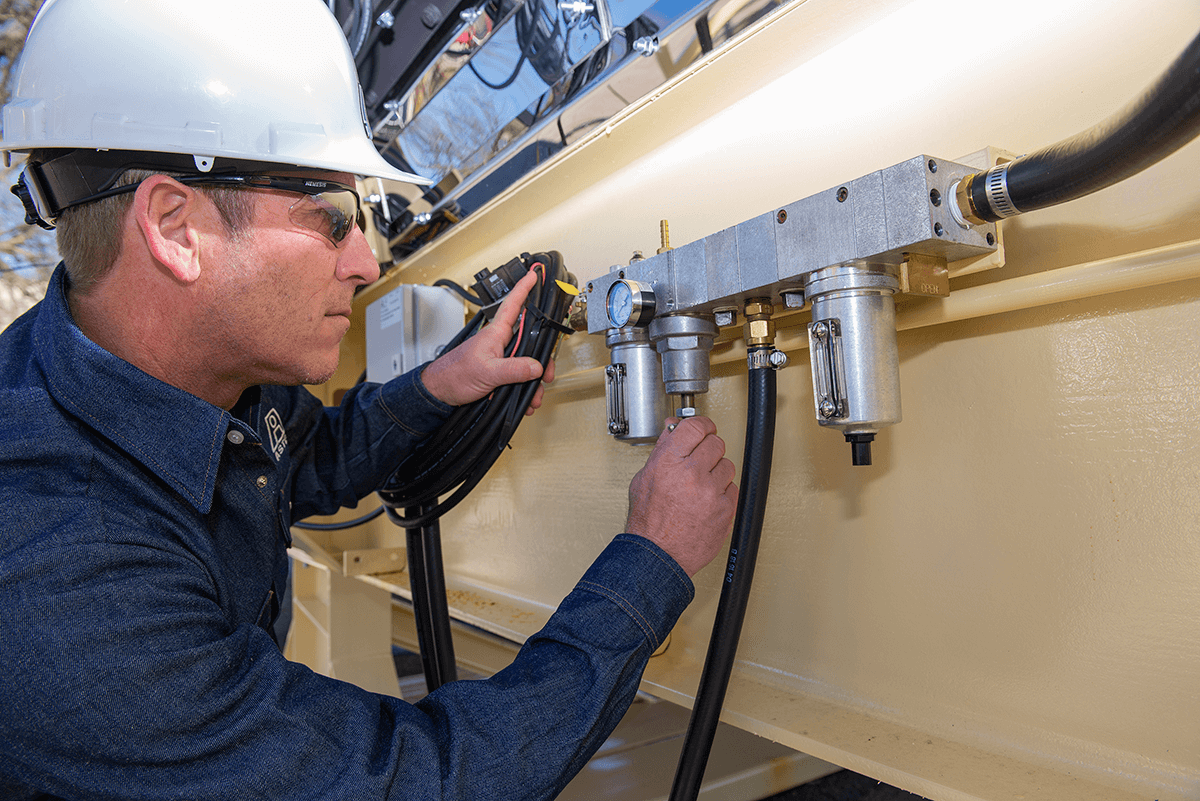

“The plant goes right from the hands of the Construction Team to the Service Team,” Francisco says. “That's when our experienced field service technicians start the commissioning, calibrating and training of the operators.”

Typically, Astec technicians are on site for a few weeks to be able to get operators trained, but their actual time on site will depend on the final level of comfort the operator has and re-training is available at any time.

“This is a partnership with our customers and we are available whenever they need us,” Francisco says. “When a customer comes to us and buys a plant, we know after the initial startup when we leave the jobsite and everything's operational, the customer is going to have questions that come up. We are always happy to come out and do a retraining once the customer has their own chance to operate the plant without us being right there.”

The same process above is true for every job the Construction & Service Teams assist with, from retrofits to tear downs.

“We do retrofit installs, complete plant tear downs and moves for customers and put them up at new sites. We run the whole gamut of construction,” Francisco says. “When it comes to retrofit applications, where you're trying to marry some of our new equipment up to existing equipment, whether it be Astec or whether it be a competitor's equipment, there are a lot of unknowns there. One of the things that you get when you choose us as a provider is that we have engineers that can go out and do pre-measuring and they can mitigate many of those challenges that you will face marrying up old equipment to new.”

These engineers are able to verify drawings and troubleshoot any areas of concern once on site. From poor installation or structural integrity of the existing equipment, to elevation changes and angles, the Astec team can determine what is needed before any parts are ordered.

“Those are all things that you can overcome in the field, but if you know that up front, you have all of the welding and fixtures built in advance and that makes for a much easier retrofit experience,” Francisco says. “Retrofits can be challenging, but I think we're in a very good place with what we do with our project management and field engineering where we go out and premeasure before we do any delivery of equipment.

“We want our customers to buy the plant the first time from their sales team and then the second time, we want them to buy because of what we do on the service side of it,” Francisco adds.

Trusted Partnership

Astec, Inc. knows that the Construction and Service Teams are integral to that goal.

The construction team alone consists of 32 employees dedicated to new plant installs and retrofits. These individuals have over 400 years of combined experience getting to know how each plant is manufactured, installed and successfully run each day.

“That gives our team a significant advantage over any of the other construction crews or our competitors, because they all have a very deep and broad knowledge of our equipment. They’ve built that equipment in the past” Francisco says. “When they carry that expertise out to the field, it makes it very easy for them to be able to make changes or correct problems that could come out during the construction process because they have that experienced fit and fabrication knowledge.”

Add the service team to this group and your plant purchase has over 100 individuals on hand to make sure the purchasing process goes smoothly from start to finish.

“When we sell a plant to our customers, and the customer receives the plant, Astec is given the opportunity not only to sell them the plant, but it allows us to do the construction portion of it and then do a direct handoff to our service team,” Francisco says. “We're going to do all of our calibrating, operator training and commissioning and then we hand it off to the customer at the end. So basically, from the very beginning of the sale until when the product is handed over to the customer, it’s always being touched by someone at Astec.”

In this way, Astec is a true partner with each sale, always behind the scenes making sure the customer has everything they need to be successful.