What’s the difference between steam and thermal fluid?

Highlights

- Thermal Fluid Heaters are safer than traditional boilers

- Thermal Fluid Heaters cost less to maintain and operate

- There is no need for water treatment with a Thermal Fluid Heater

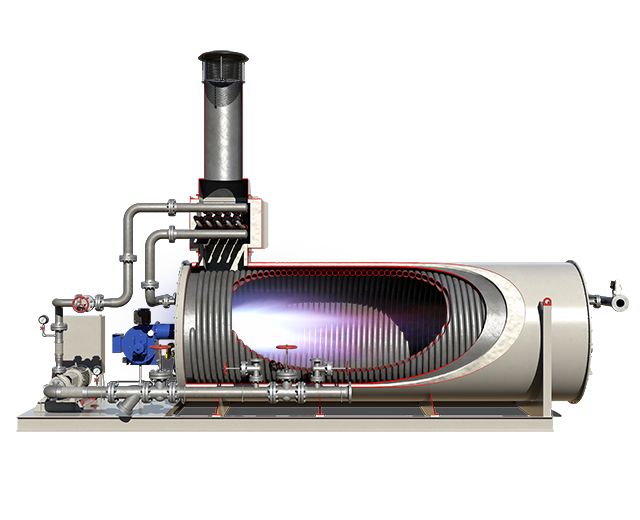

Consider, for example, a fired boiler that has a burner that fires into a combustion chamber. Combustion gases flow through tubes and out of an exhaust stack. Water surrounding the hot chamber and tubes turns into steam. The steam expands, thereby pressurizing the shell of the boiler. This same pressure causes the steam to move into piping, which carries it to heat exchangers that heat other things.

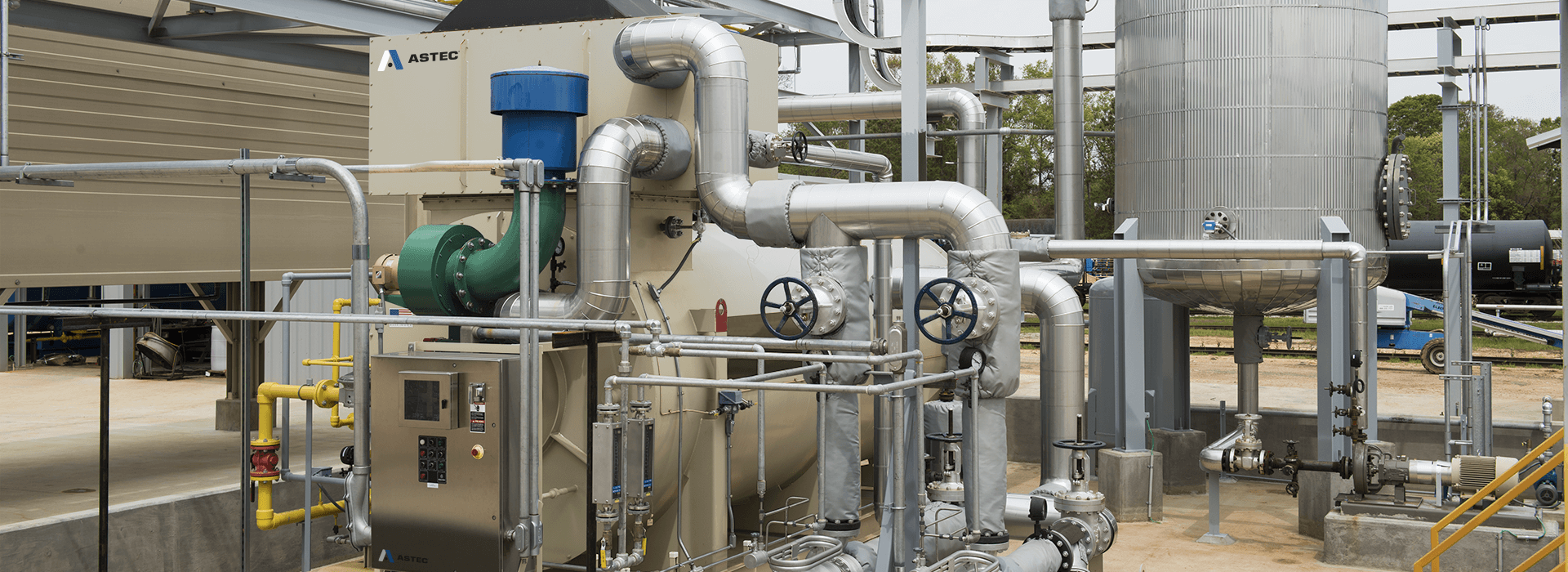

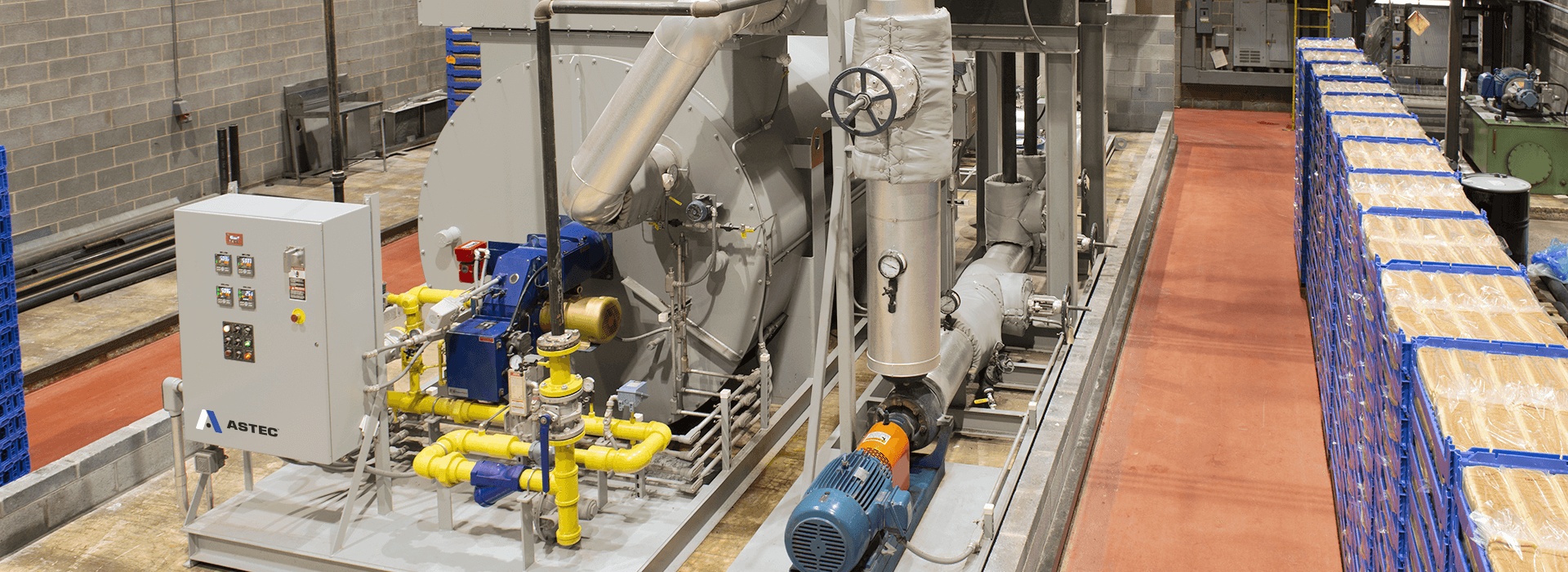

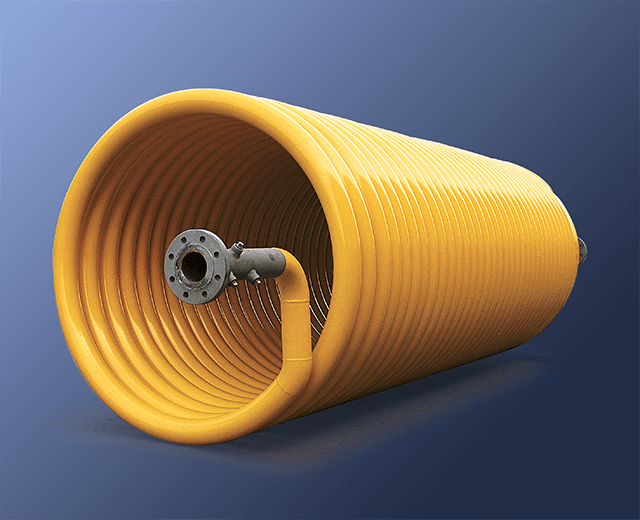

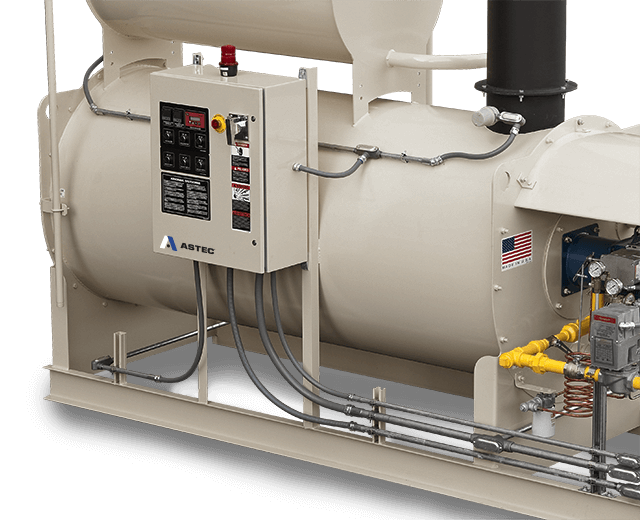

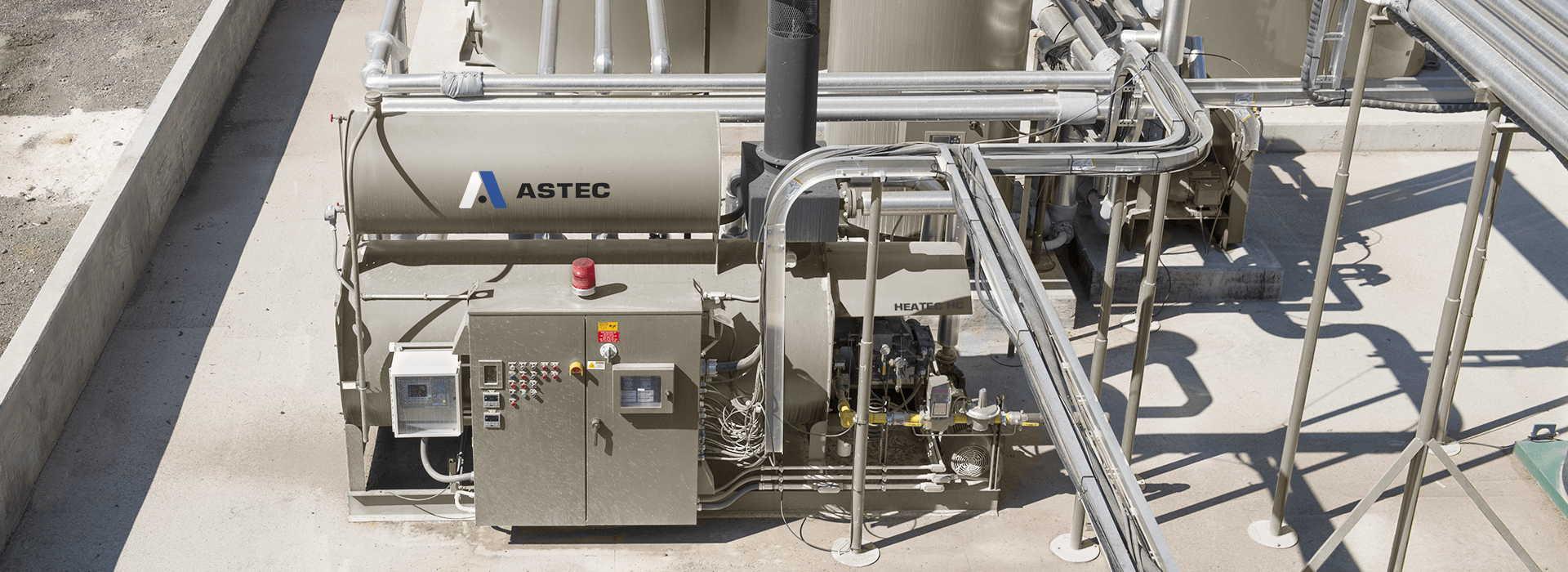

Thermal fluid heaters typically fire through a helical coil or a serpentine coil. Energy from the flame heats the coil by radiation and convection. The hot coil heats thermal fluid pumped through it. The thermal fluid heats coils in heat exchangers. Unlike a boiler, the heating process does not pressurize the heater's shell, the coil, or the piping.

Boilers are nearly always cheaper, but often cost considerably more to maintain and operate. Moreover, boilers are far more hazardous than thermal fluid systems.

Another important advantage of a thermal fluid system is the lack of corrosion, lime deposits and scale. Therefore, there is no need for water treatment, as required for boilers. Other advantages include no annual shutdowns for inspection, no boiler "blow-down" or wastewater cooling, no concern for freezing and no maintenance of steam traps.

If steam is required for special functions, a steam generator can be added. In that case, the thermal fluid also circulates through the tubes inside the steam generator. The tubes heat the water surrounding them, converting it into steam. Unlike a fired boiler, the heated tubes in a steam generator never get hotter than the thermal fluid flowing through them. This eliminates explosion hazards commonly associated with boilers. And because steam generators are not fired, they are not subject to restrictions for fired boilers. Steam generators do not require a boiler operator, who (in most states) must be present whenever a boiler is in operation.

Of course, the advantages and disadvantages of either system depend on the specific application, but it is always smart to consider all options when building a new plant or replacing old equipment.