Asphalt Plant Sustainability

Astec Industries is committed to continually strengthening global sustainability as we lead in the innovation of everything we do from Rock to Road.

For our customers, we will continue to be the most innovative company in our industry, offering the world most advanced, productive, durable, and environmentally friendly products. Our team is constantly working to find ways for our customers to reduce their environmental impact in user-friendly and budget-conscious ways.

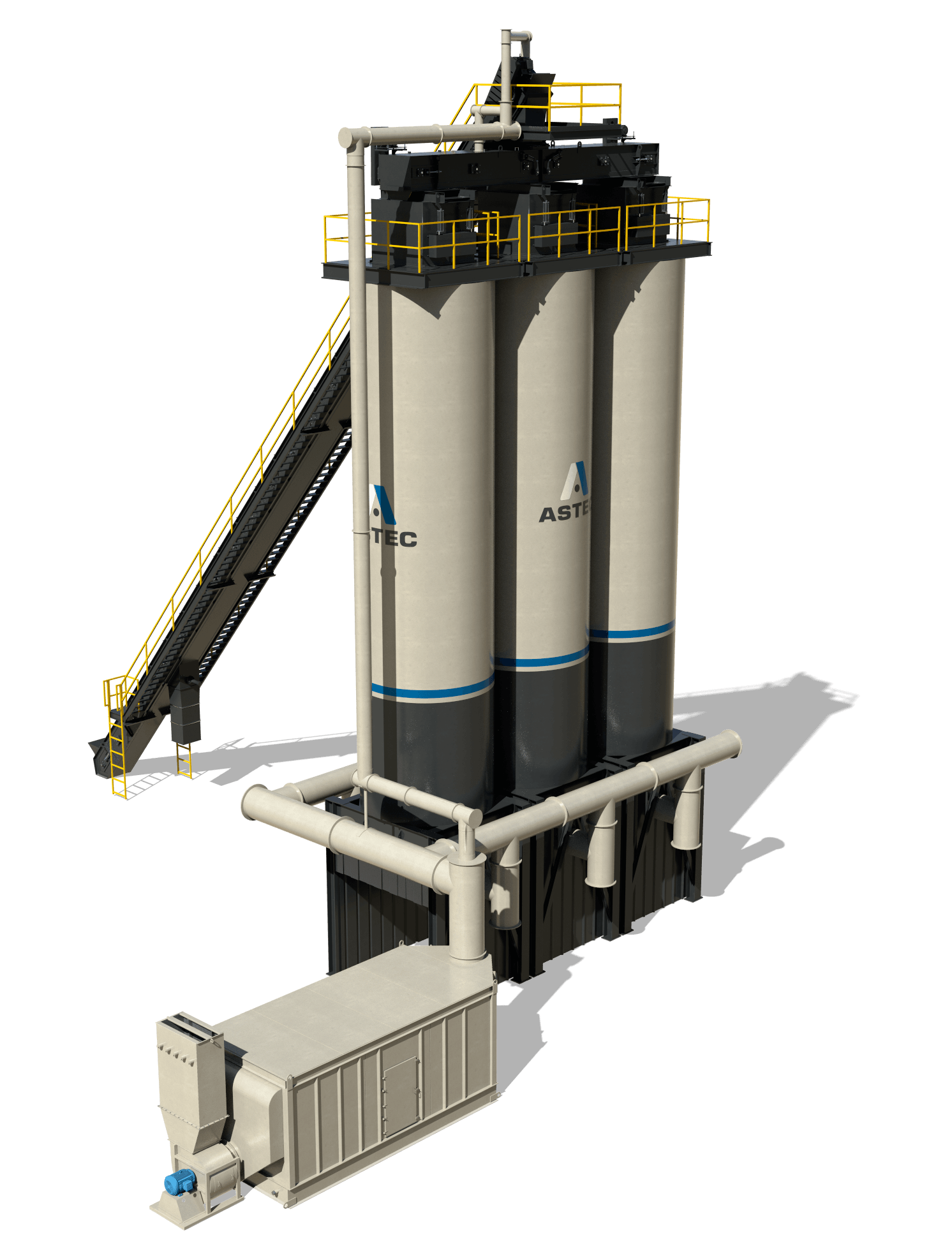

These innovations can be seen throughout an Astec asphalt mixing plant.

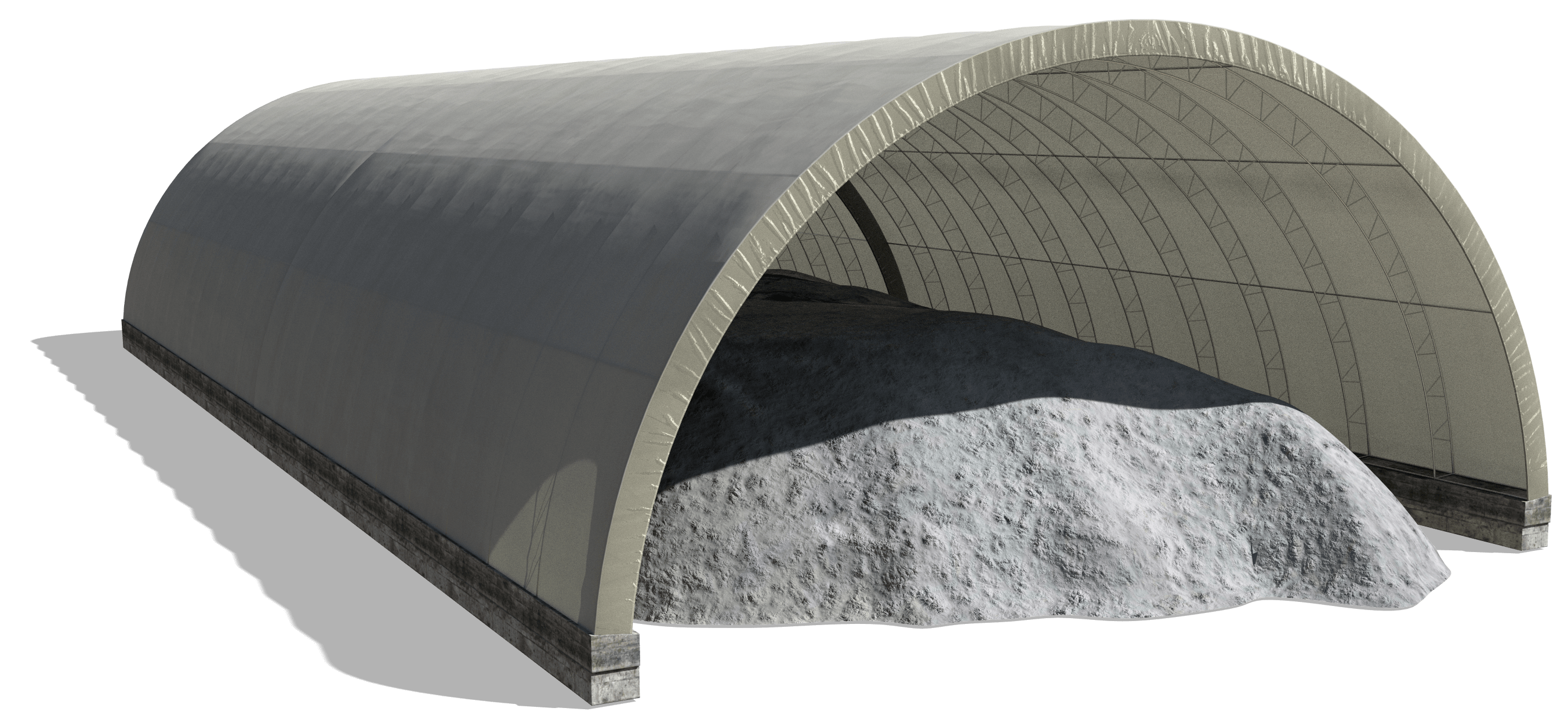

1. Stockpile Moisture Management

Knowledge of moisture levels in aggregate through real-time monitoring enables plant operators to better control burner rates and asphalt cement usage.

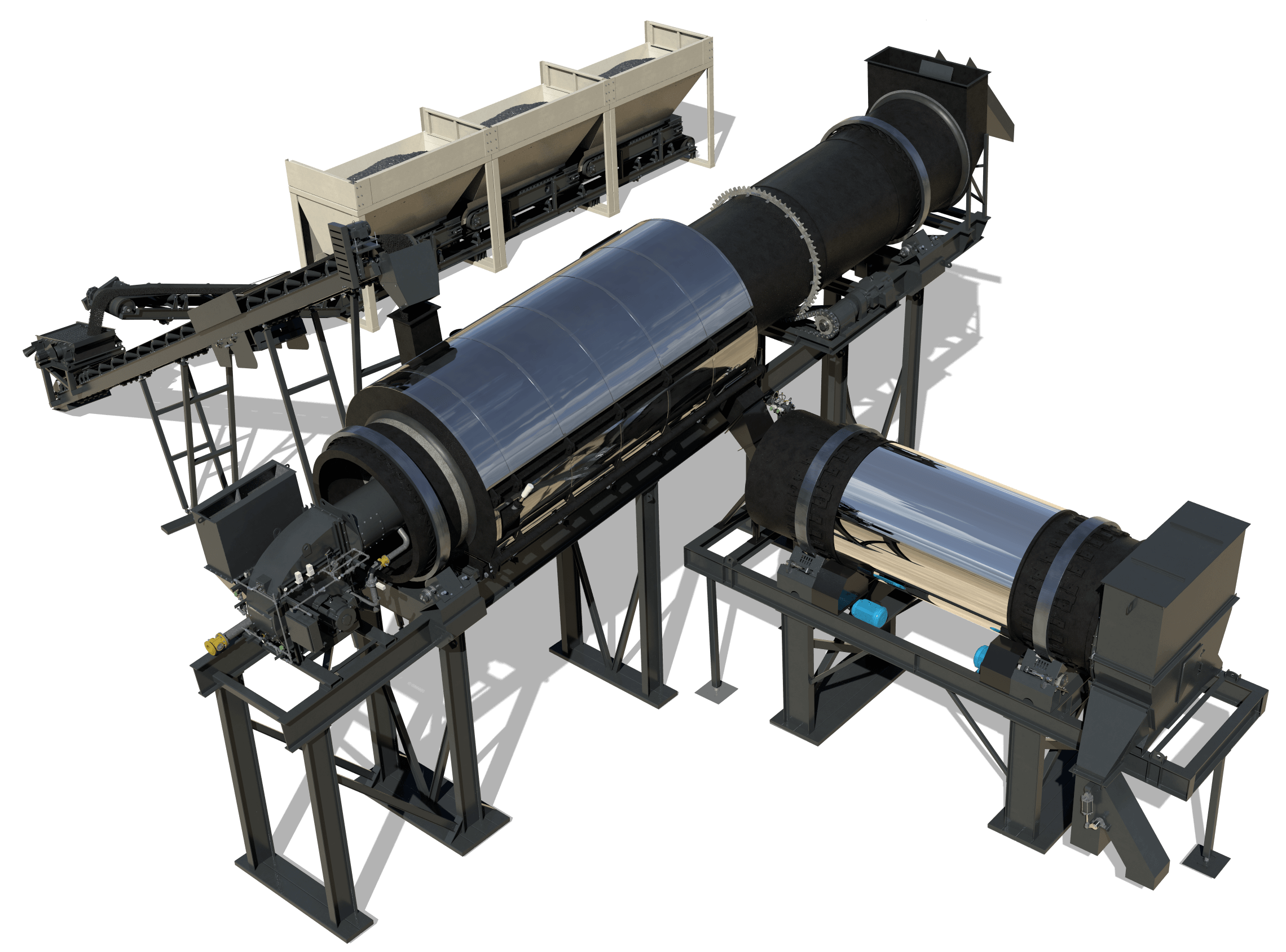

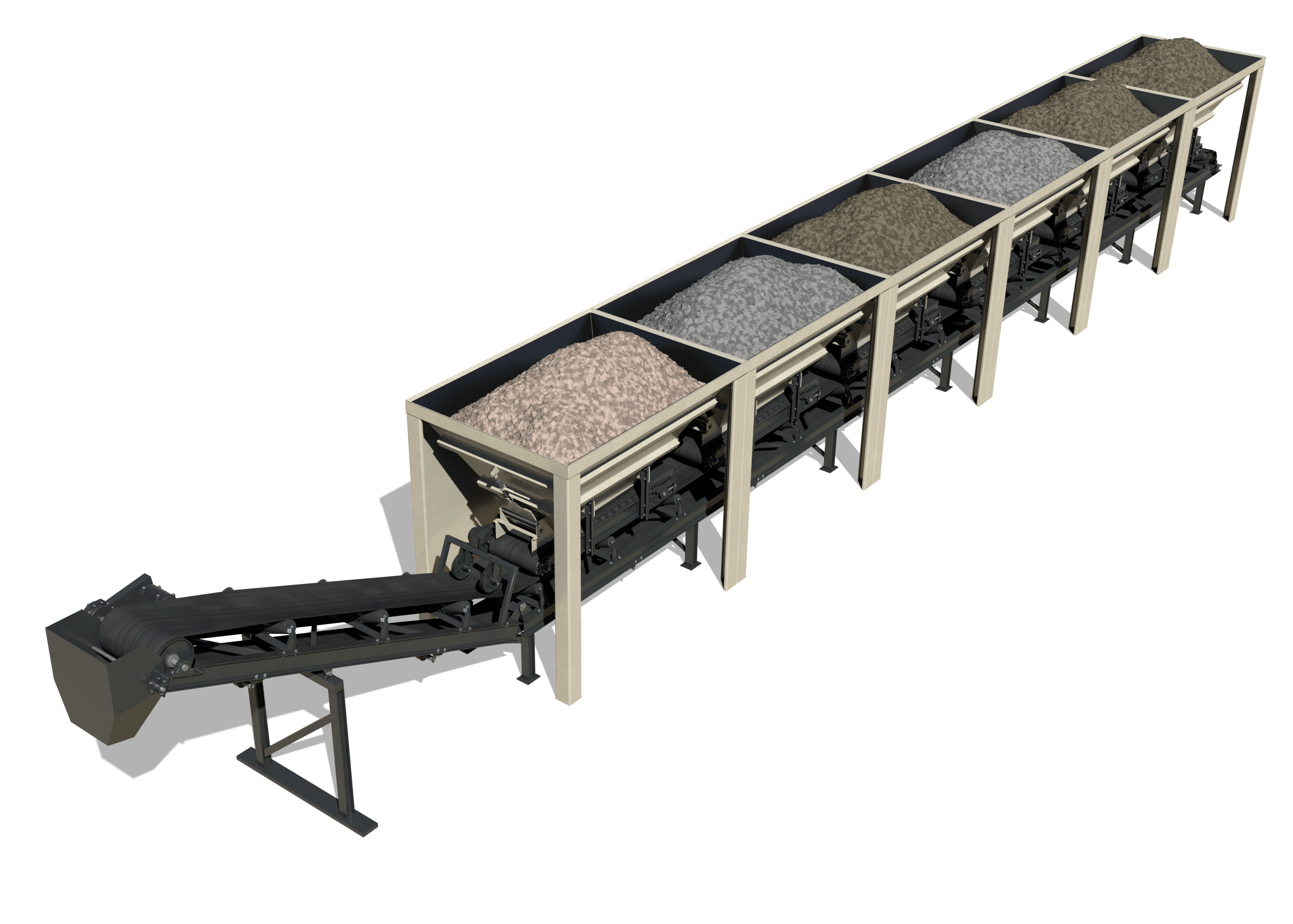

2. High RAP Capability

Increasing use of RAP when making asphalt paving mix saves both virgin aggregate and virgin asphalt cement while keeping materials out of landfills.

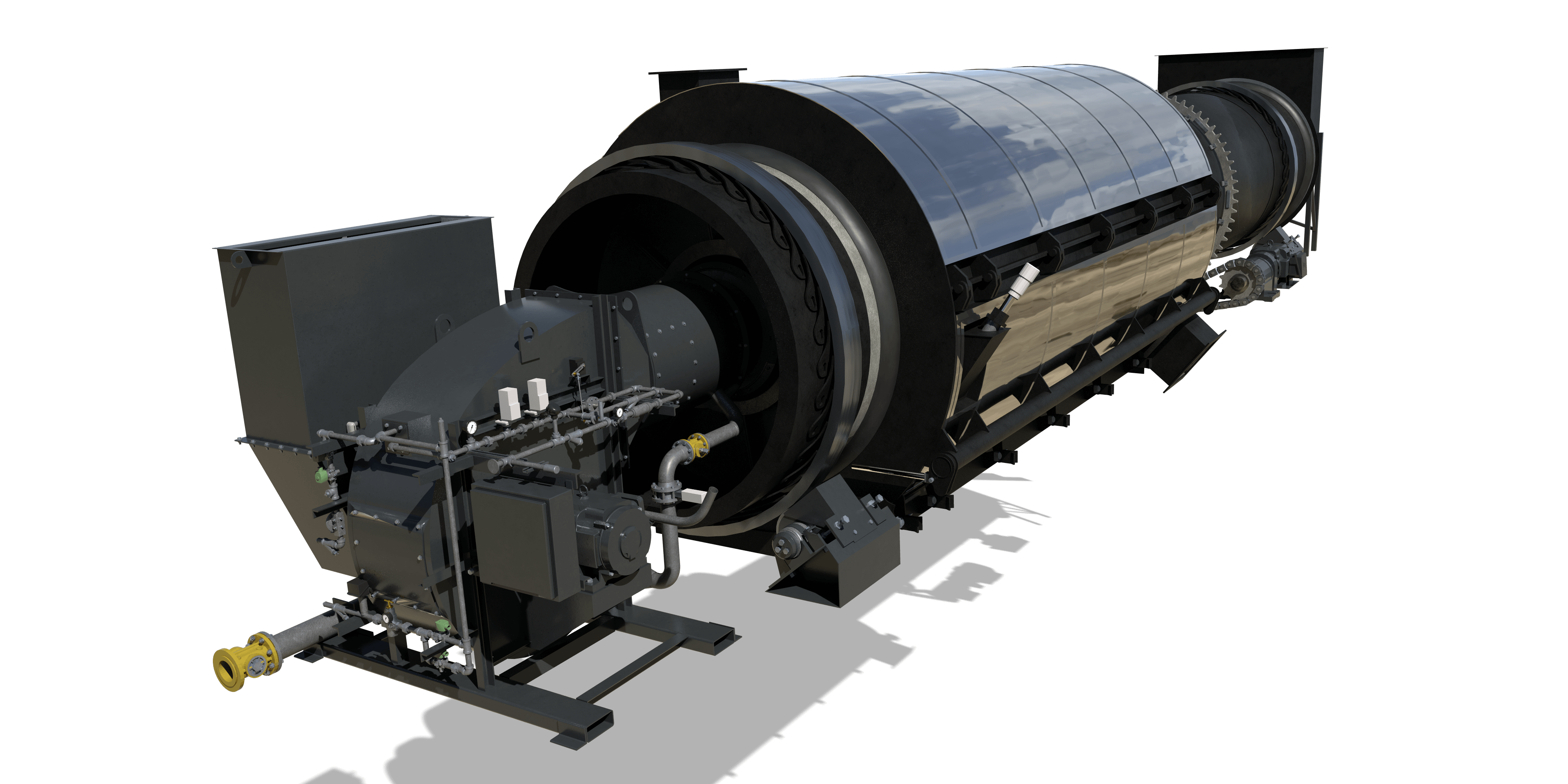

3. Alternative Fuels

Making the switch from waste oil to natural gas results in carbon footprint reductions. Additional reduction is possible by enriching natural gas with hydrogen.

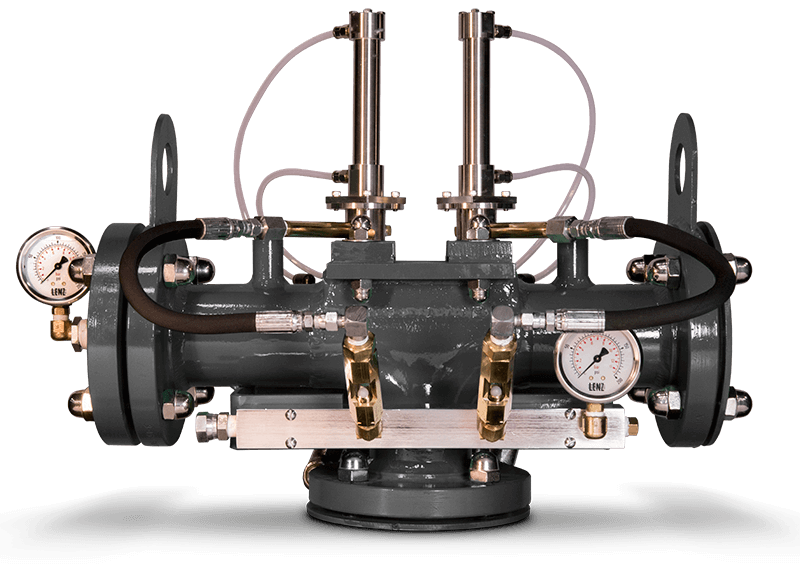

4. Real-time Moisture Measurement

Knowledge of moisture levels in aggregate through real-time monitoring enables plant operators to better control burner rates and asphalt cement usage. Contact Astec to learn more about real-time moisture measurement.

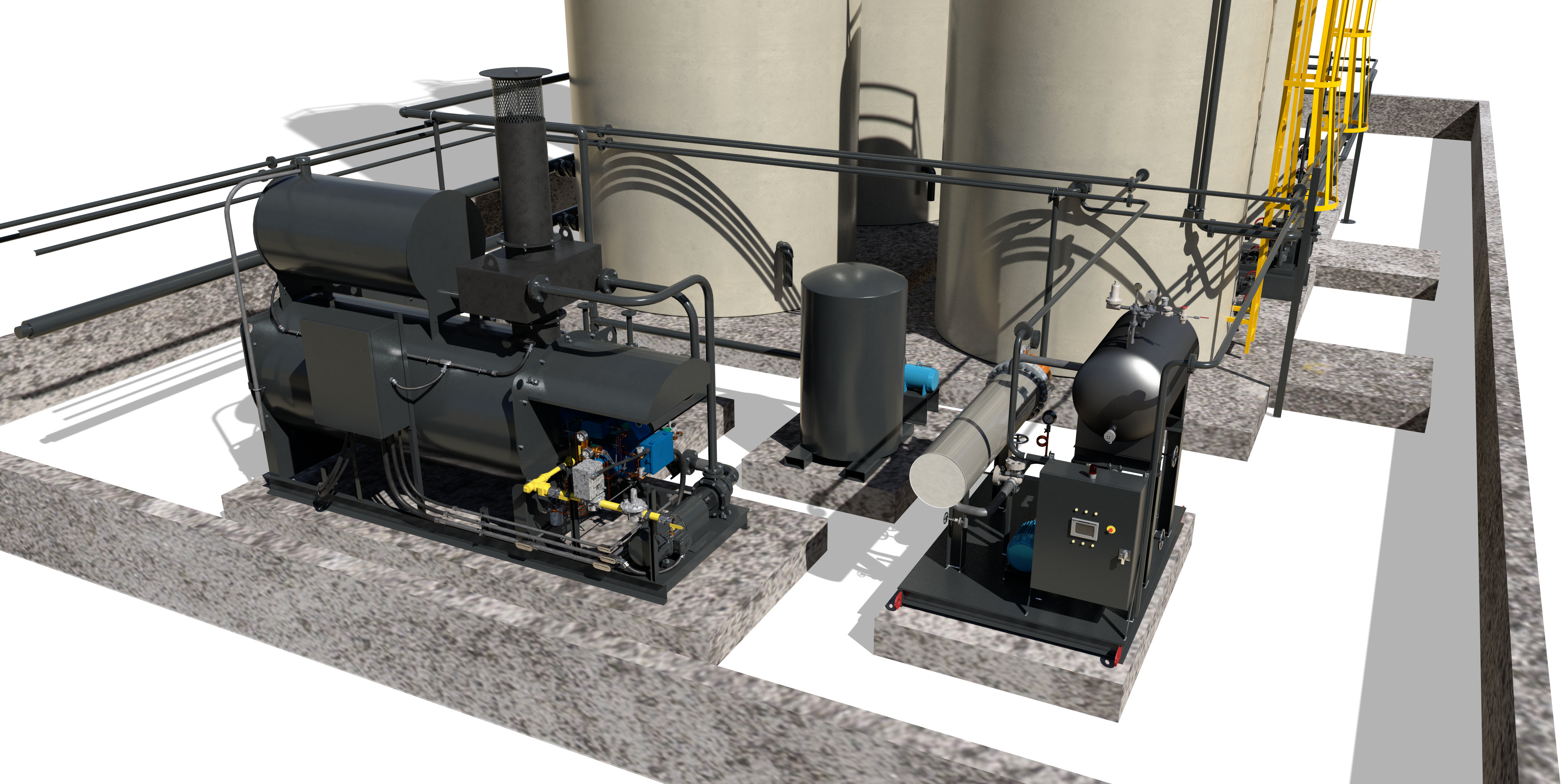

5. Electric Heating Systems

Electrical heating systems for AC tanks, drag conveyors and asphalt silos help reduce local emissions when compared to traditional methods.

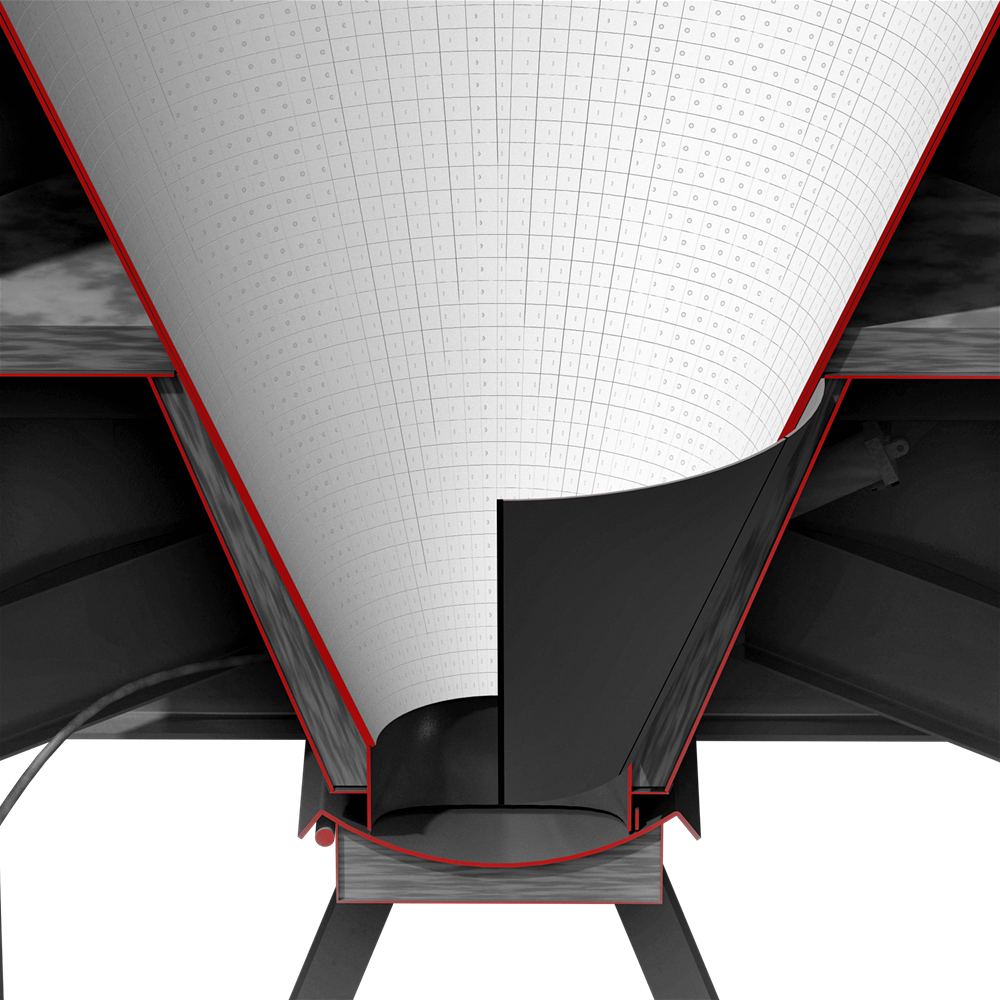

6. Warm Mix Asphalt

Reduce energy consumption, lower emissions, and minimize blue smoke by using an Astec Green System.

7. Blue Smoke System

A blue smoke system captures harmful gasses as well as odors that escape when asphalt is transferred from the mixer to the storage silos and trucks.

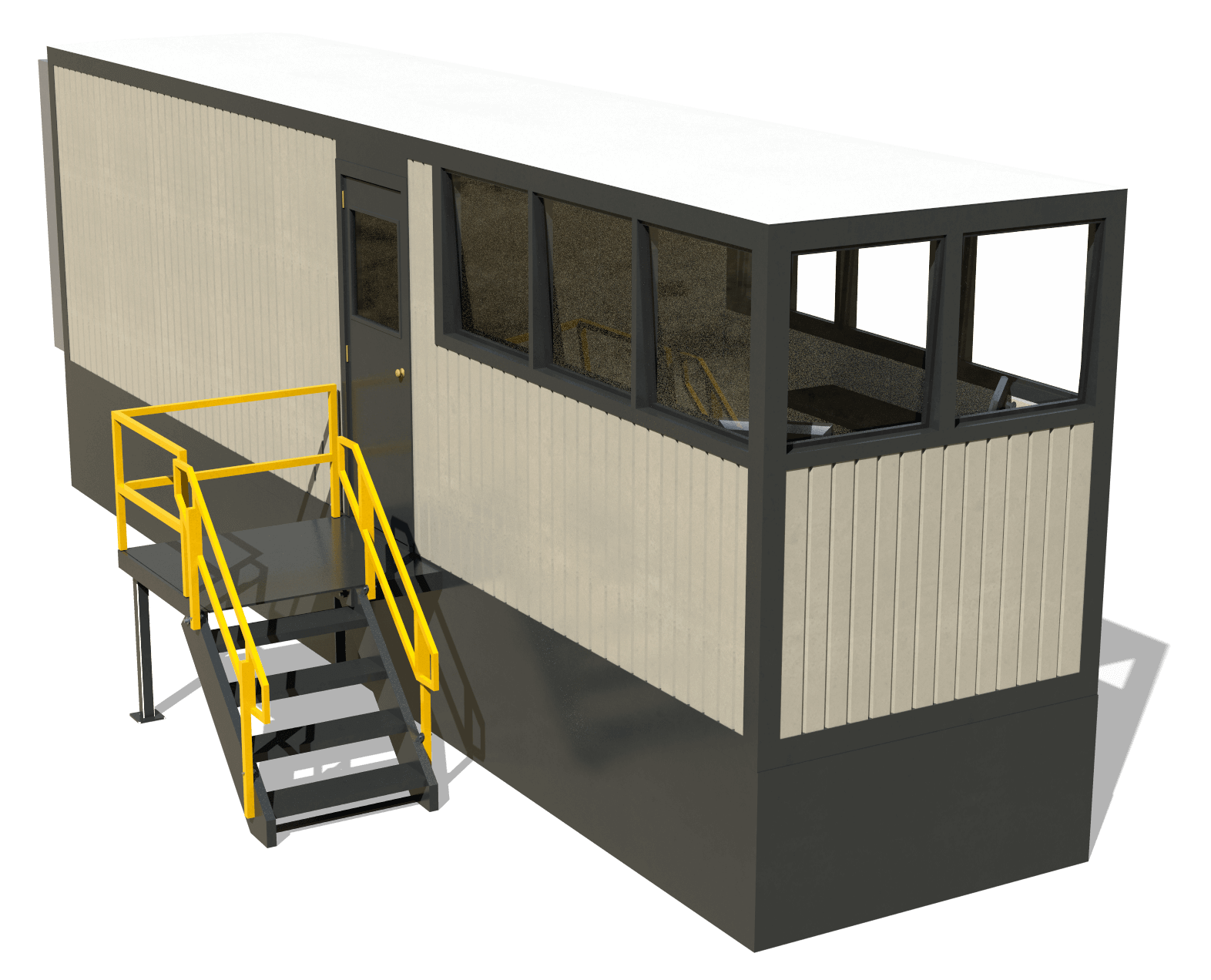

8. Power Factor Correction, Variable Frequency Drive

Use of Variable Frequency Drives (VFD) and EPac Power Factor Correction improves energy efficiency and can reduce utility penalties for poor power factors.

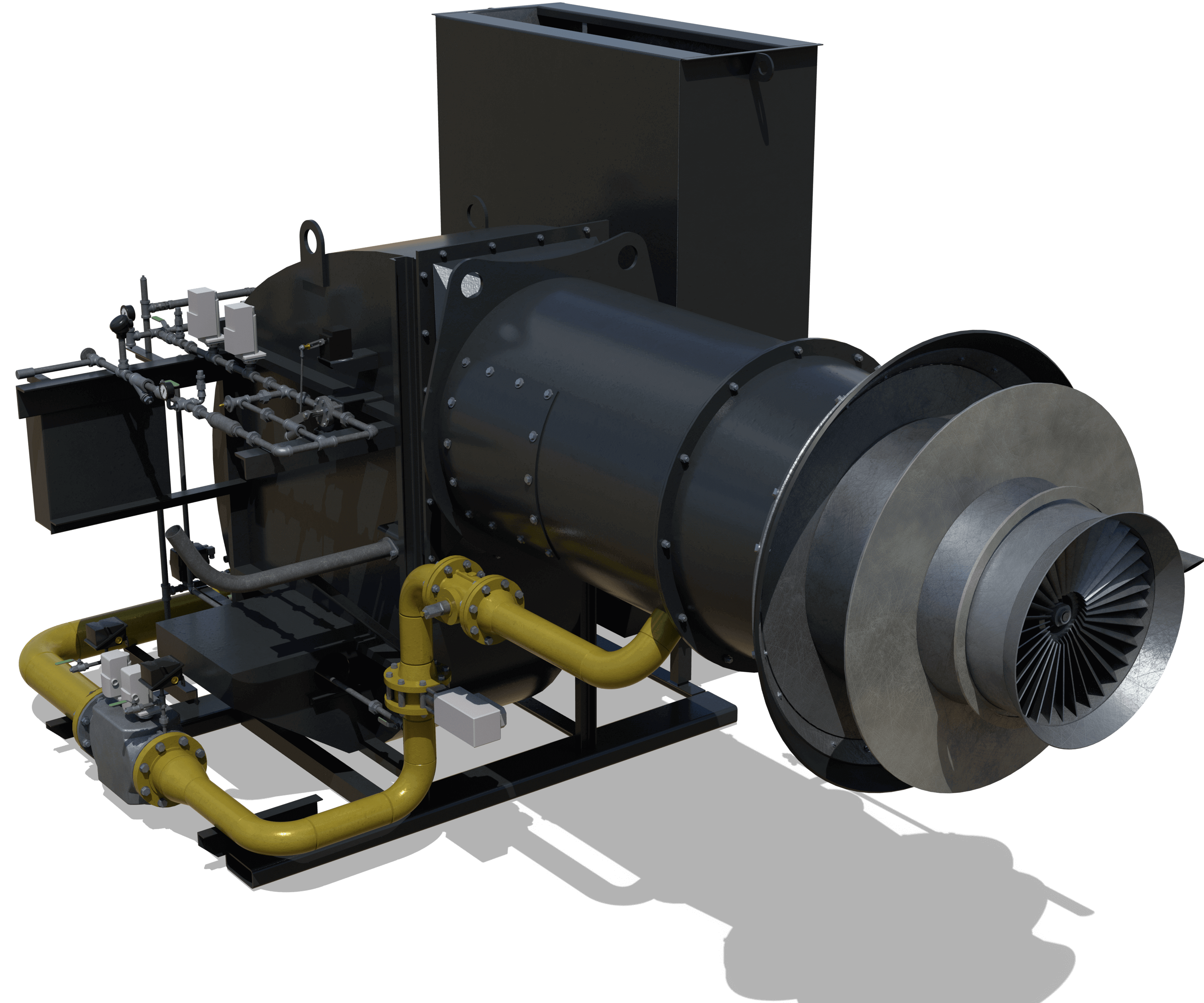

9. Low Emission Burners

Astec's burner technology can meet the most stringent pollutant emissions requirements.

10. Carbon Footprint Quantification

Astec is developing calculations for determining the operational carbon footprint of its asphalt plants.

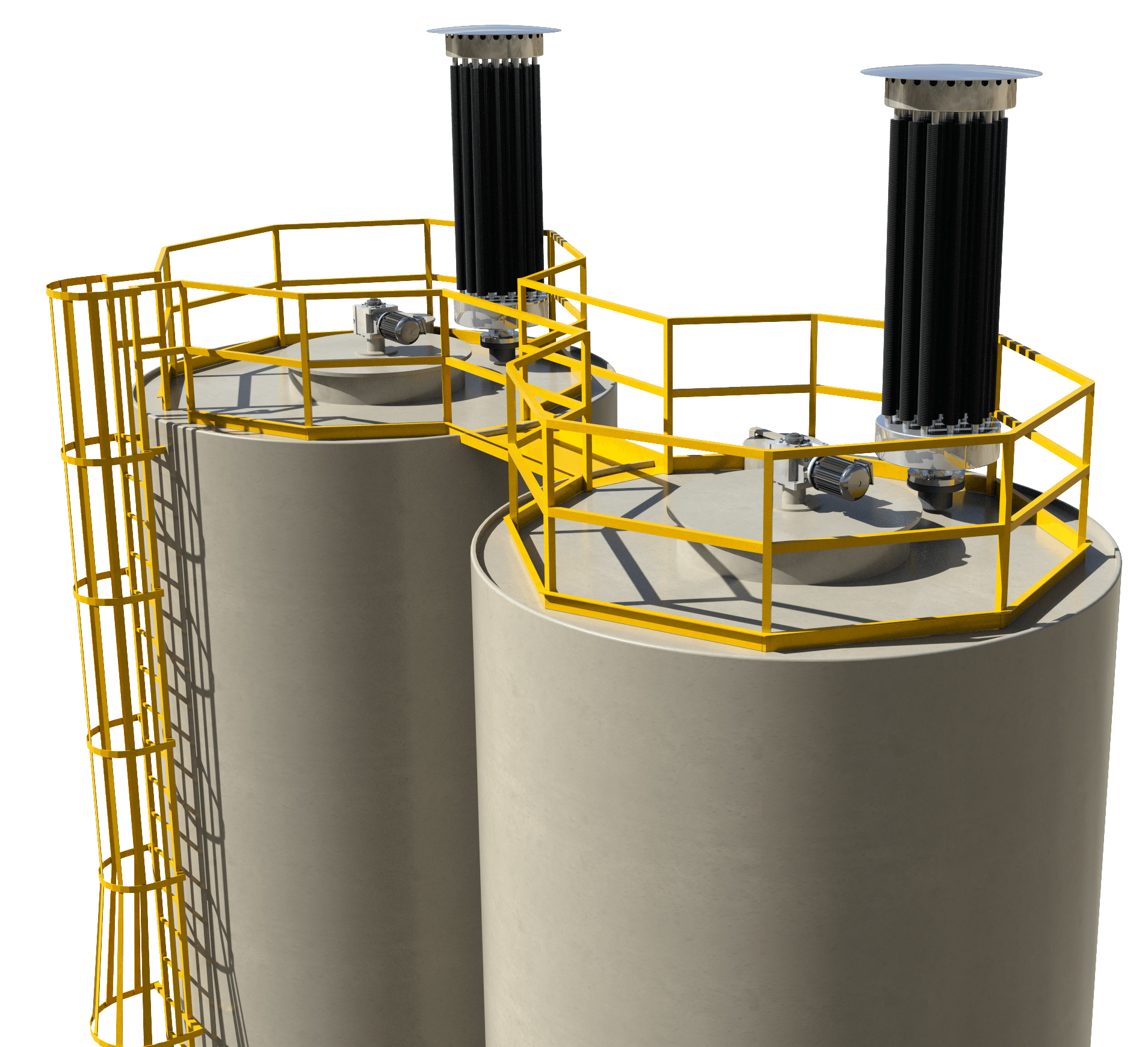

11. Vent Condensers

Adding vent condensers to liquid asphalt cement tanks reduces odors and visible emissions during tank loading operations.

12. Charcoal Scrubbers

Incorporate charcoal scrubbers to remove pollutants from fumes emitted during tank loading operations.