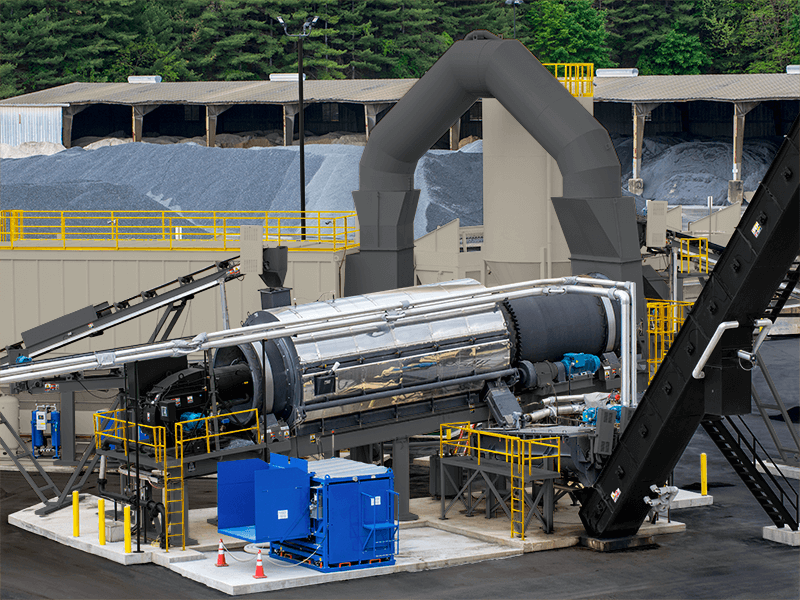

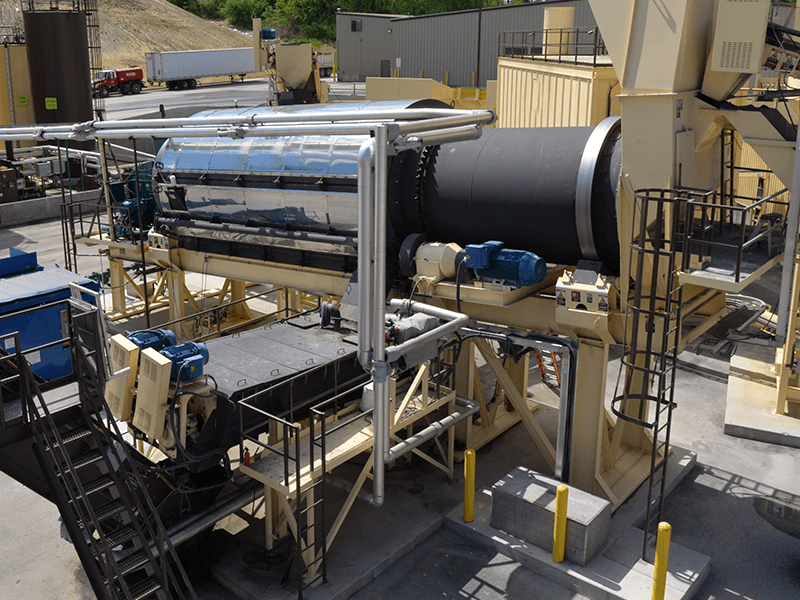

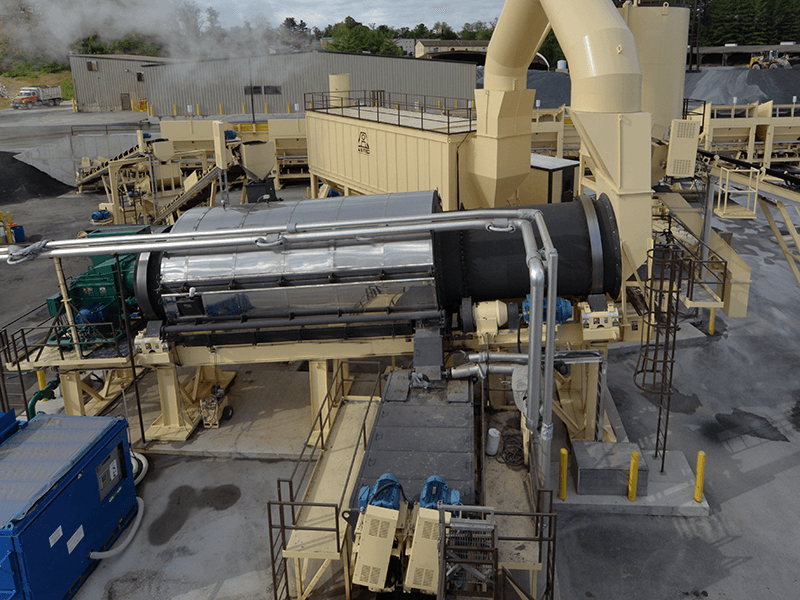

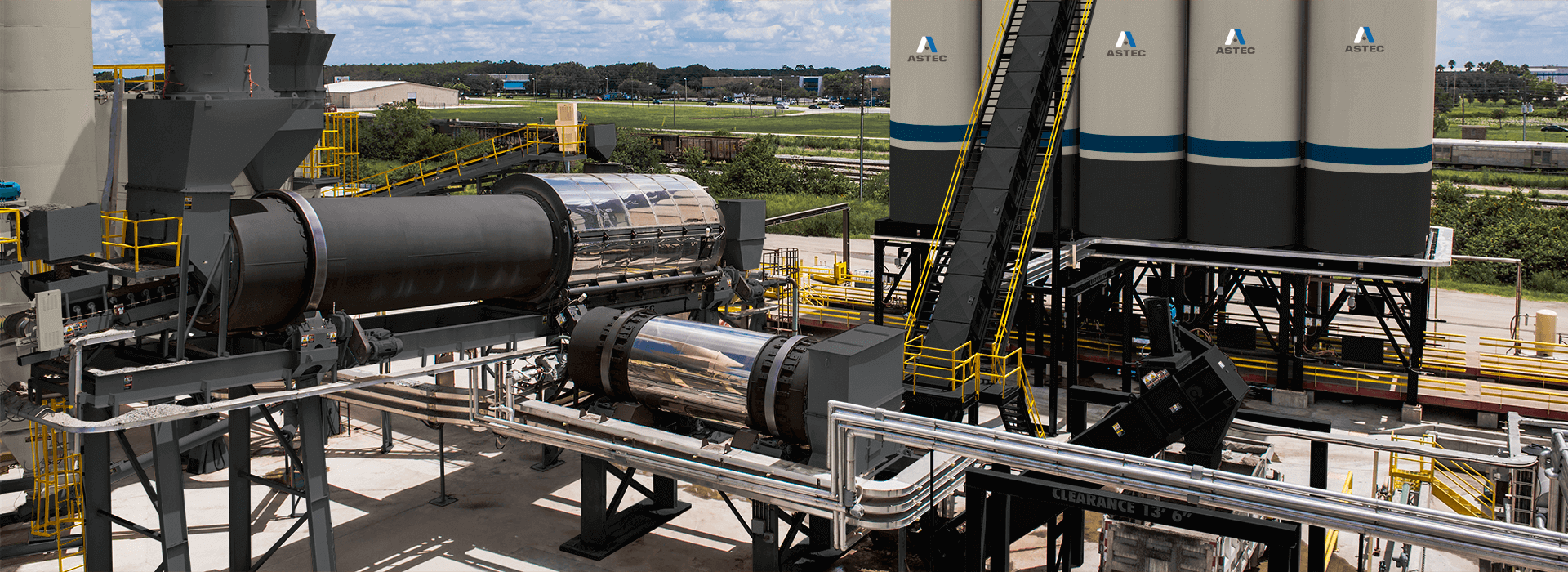

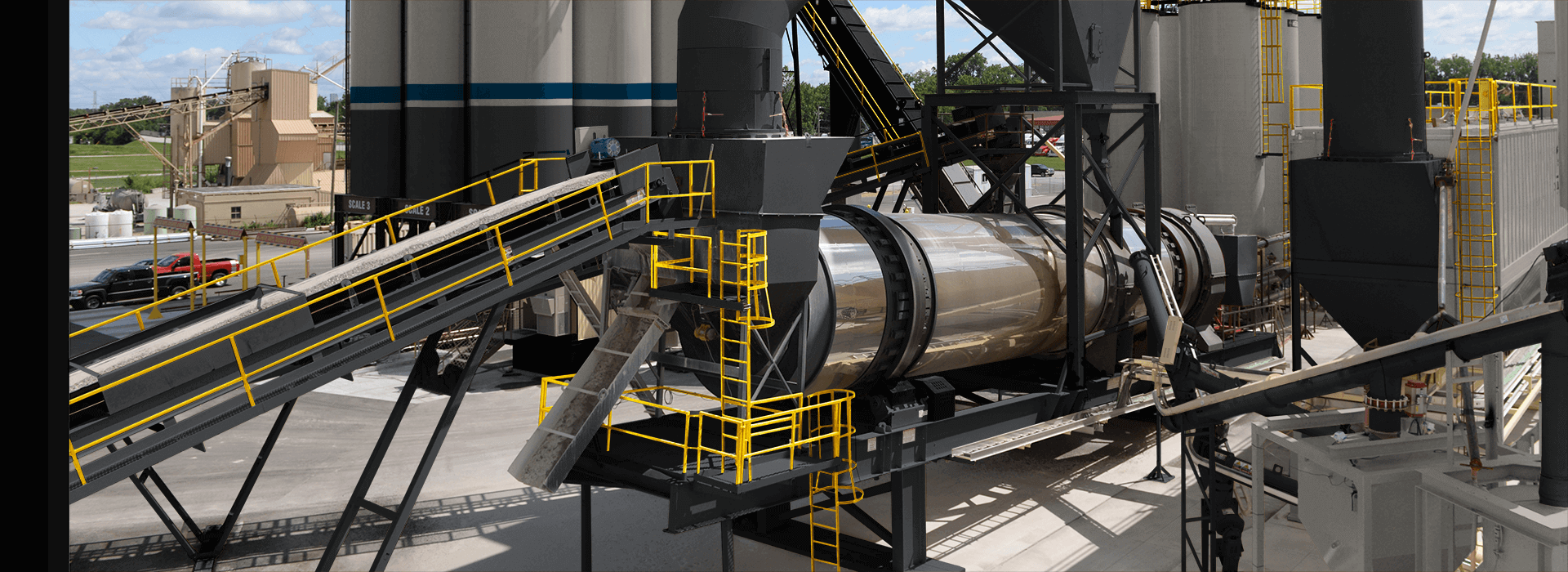

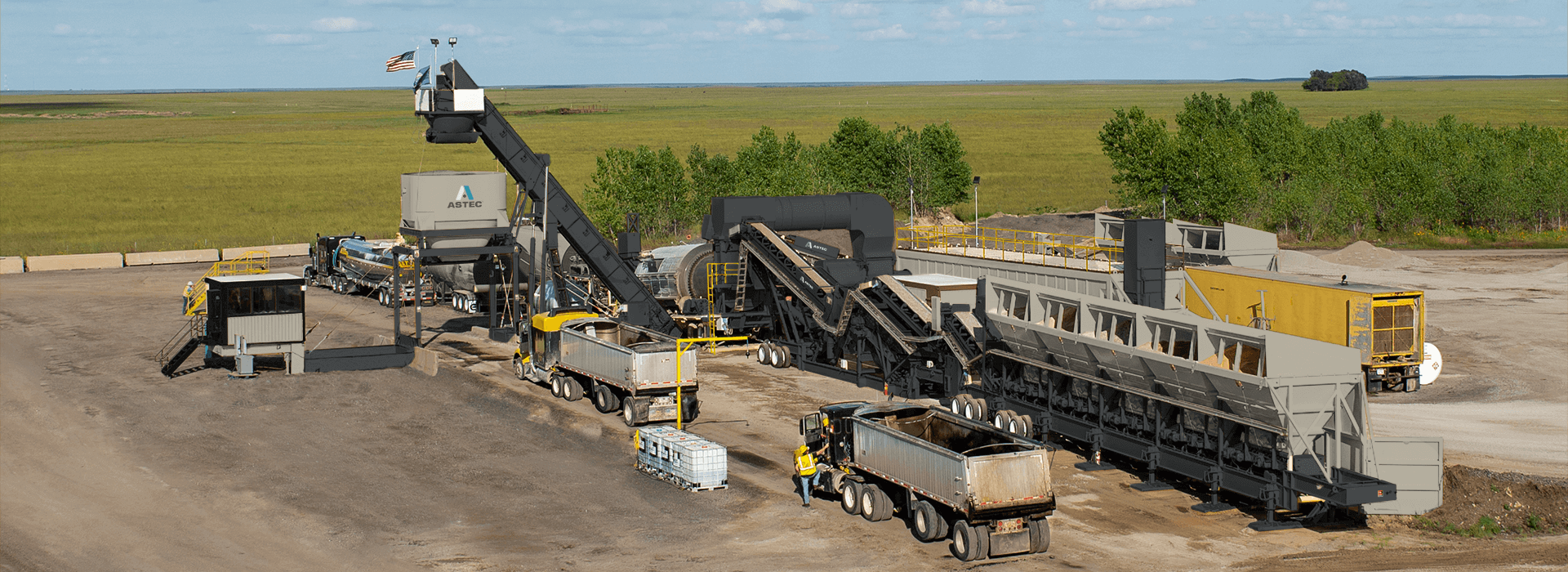

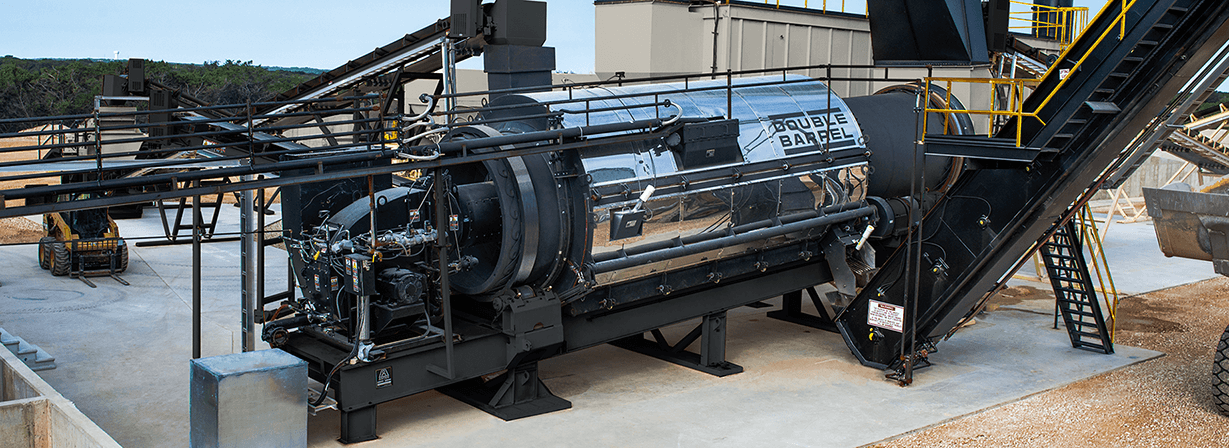

Astec Double Barrel® X Drum Mixer

Overview

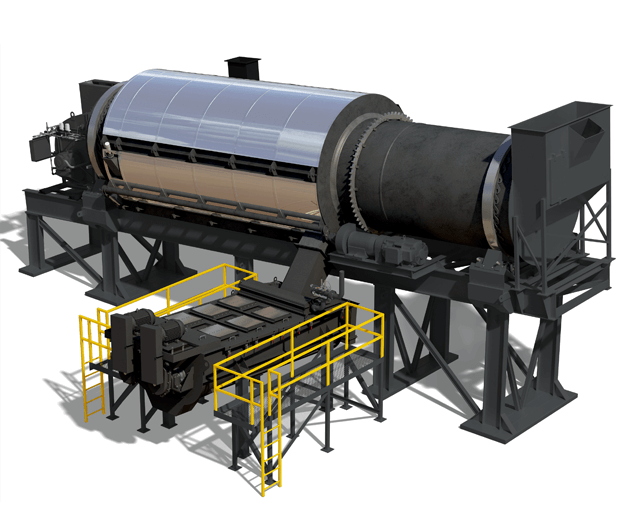

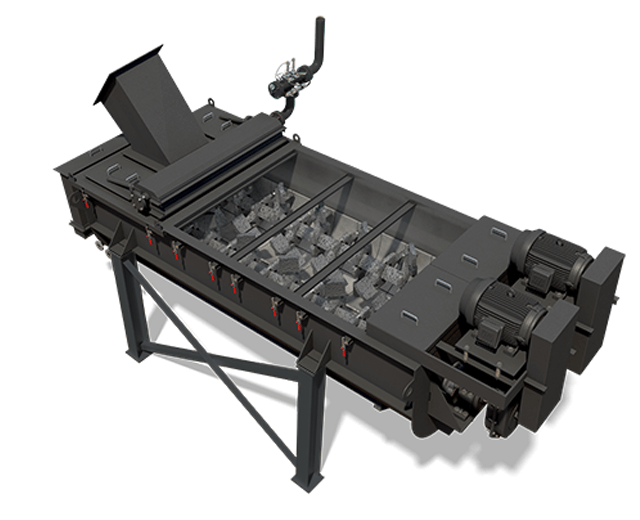

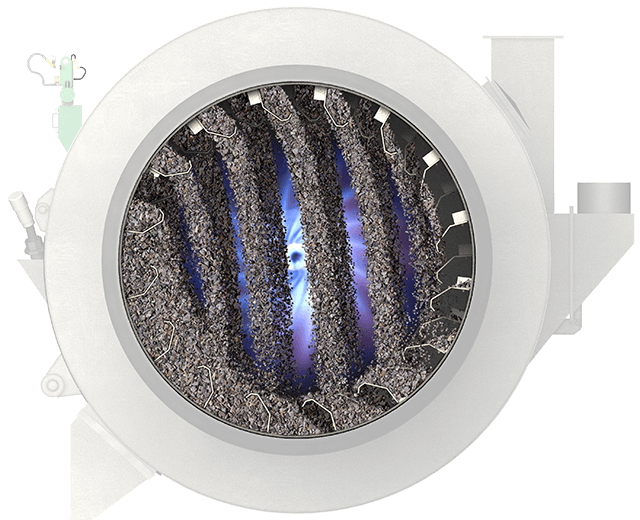

Drum Dryer with External Mixer

The Double Barrel X system separates the drying process from the mixing process, thereby providing a very reliable tool to be used for the purpose of recycling reclaimed asphalt pavement (RAP). With a Double Barrel X system, a plant can process both warm and hot asphalt mixes with up to 50% RAP content while maintaining zero opacity at the stack.

The Double Barrel X technology allows for RAP to be pre-conditioned through the external part of the DBX dryer, flashing off moisture in the drum, thus eliminating the problems associated with scavenger systems.

Double Barrel X

Applications

-

![]()

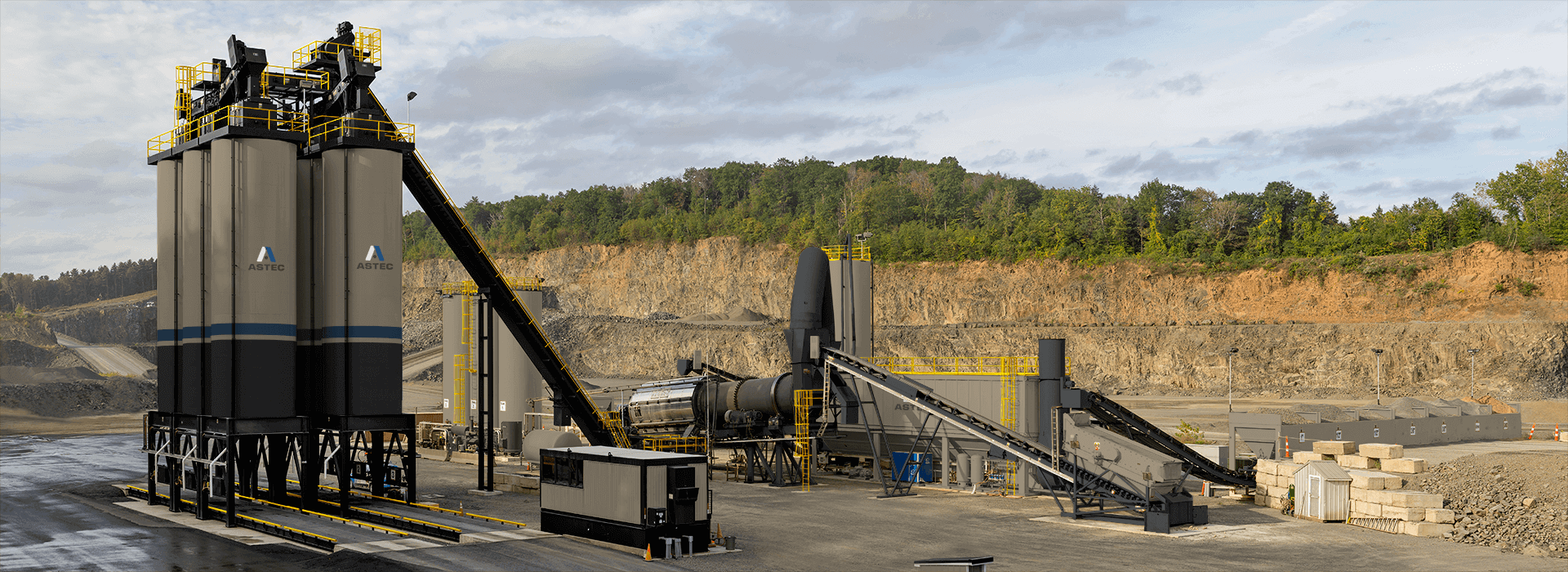

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More -

![]()

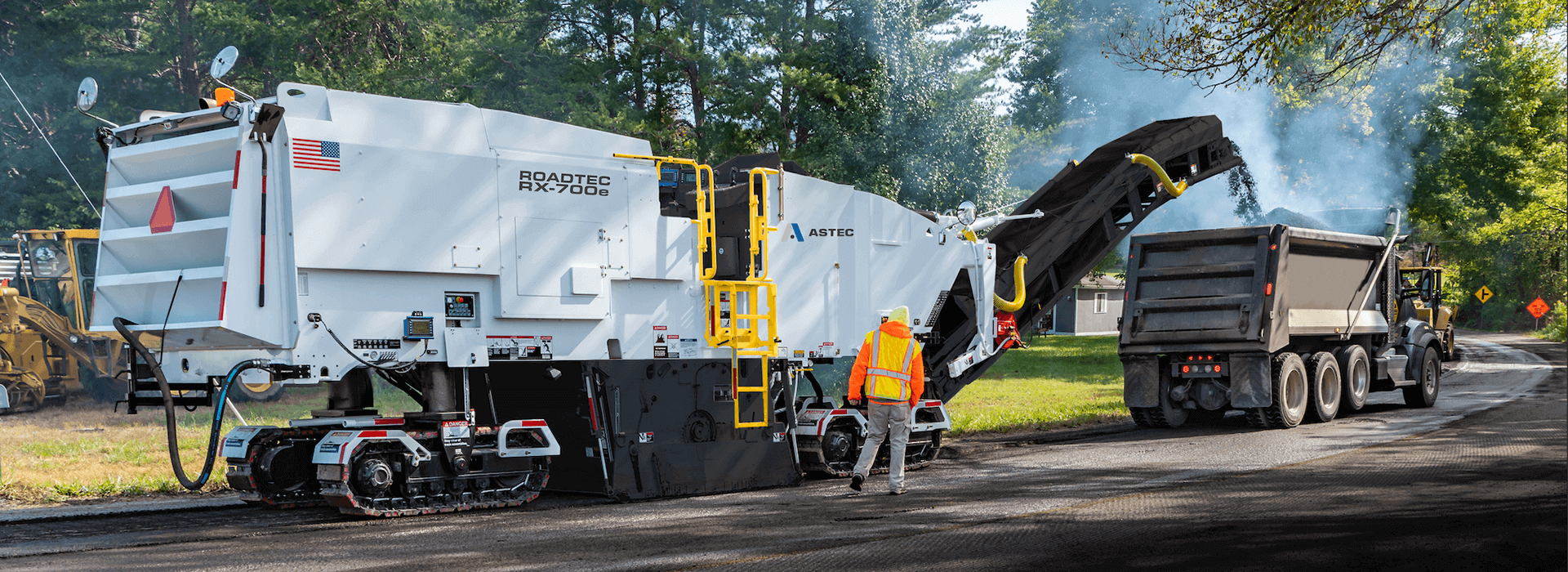

Recycled Asphalt Pavement

Recycled asphalt pavement (RAP) is asphalt paving material recovered from old road beds either by milling or excavation.Learn More

Downloads

Key Specifications

| Drum Size (m) | Mixing Chamber Size (m) | Metric Tons Per Hour (MTPH) |

|---|---|---|

| 1.8 x 10 | 5. | 181 |

| 2.1 x 11.2 | 5.7 | 272 |

| 2.4 x 11.5 | 6.4 | 362 |

| Drum Size | Mixing Chamber Size | Tons Per Hour |

|---|---|---|

| 6' x 33' | 19' | 200 |

| 7' x 37' | 19' | 300 |

| 8' x 38' | 21' | 400 |

| Drum Size (m) | Mixing Chamber Size (m) | Metric Tons Per Hour (MTPH) |

|---|---|---|

| 1.8 x 10 | 5.7 | 181 |

| 2.1 x 11.5 | 6.7 | 272 |

| 2.4 x 12.5 | 6.8 | 362 |

| 2.7 x 14.3 | 6.8 | 453 |

| 3 x 15.2 | 6.8 | 544 |

| Drum Size | Mixing Chamber Size | Tons Per Hour |

|---|---|---|

| 6' x 33' | 19' | 200 |

| 7' x 38' | 22' | 300 |

| 8' x 41' | 22.5' | 400 |

| 9' x 47' | 22.5' | 500 |

| 10' x 50' | 22.5' | 600 |

All specifications subject to change without notice.