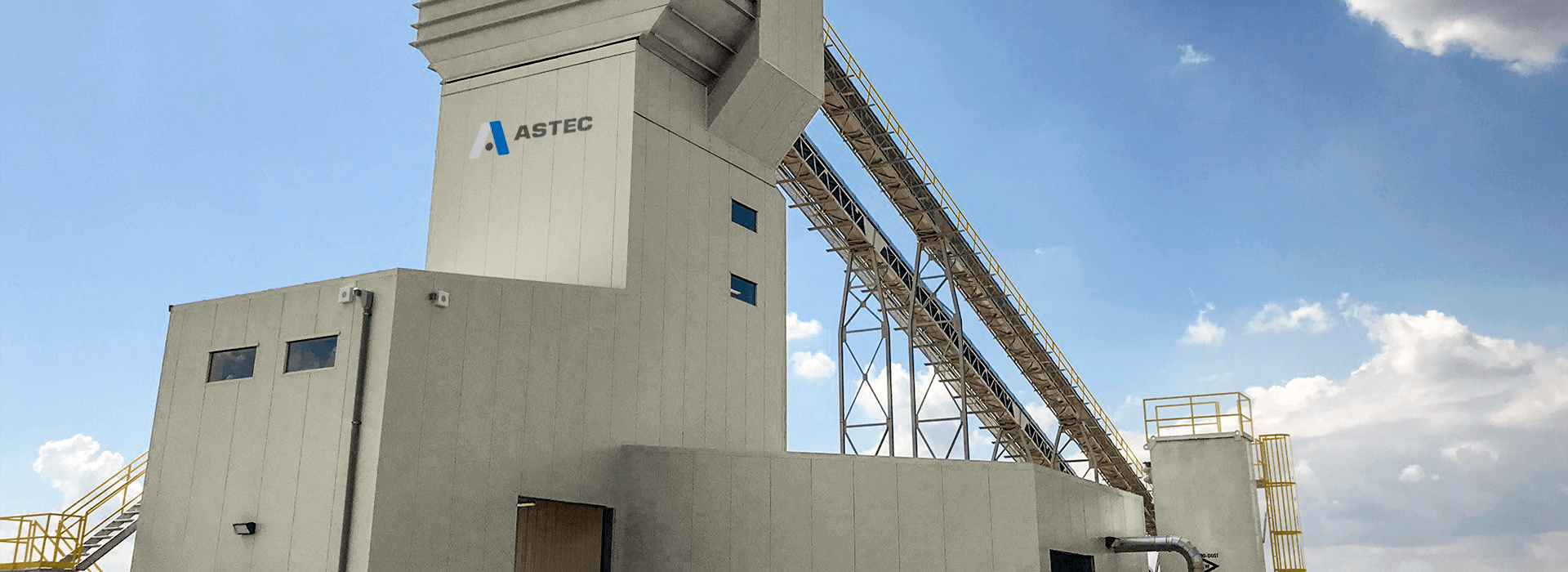

Astec Concrete Conveyors

Overview

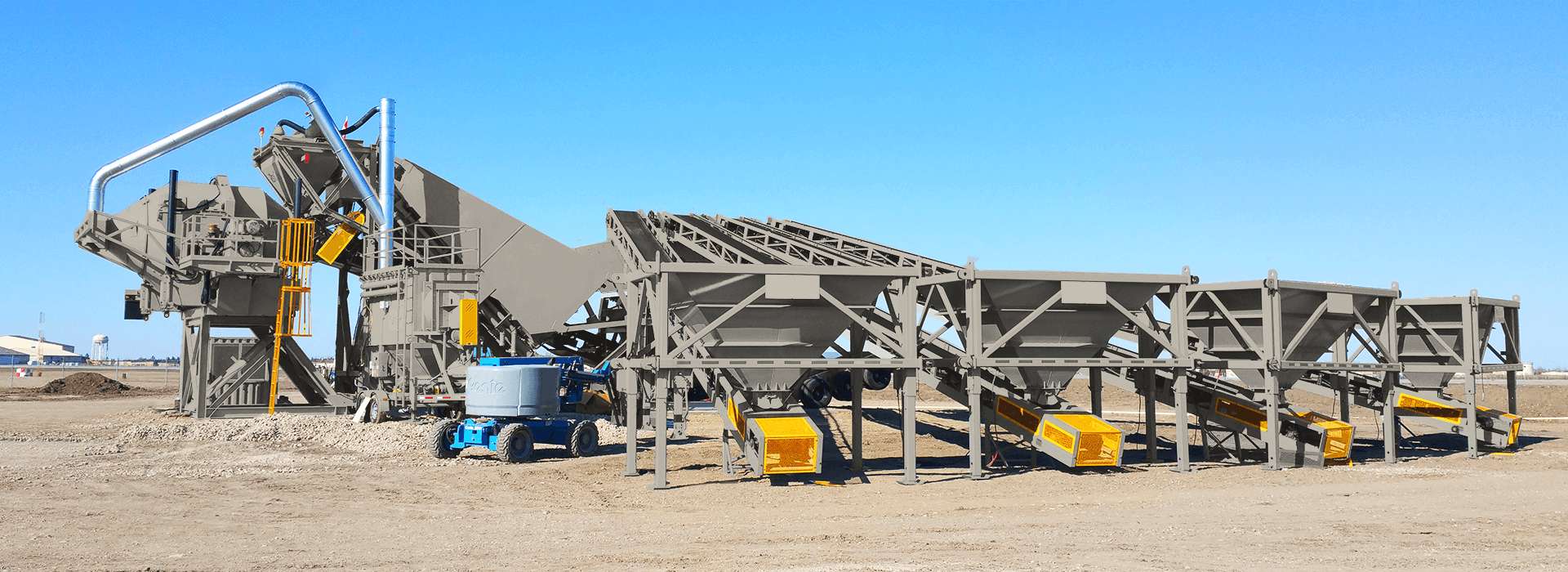

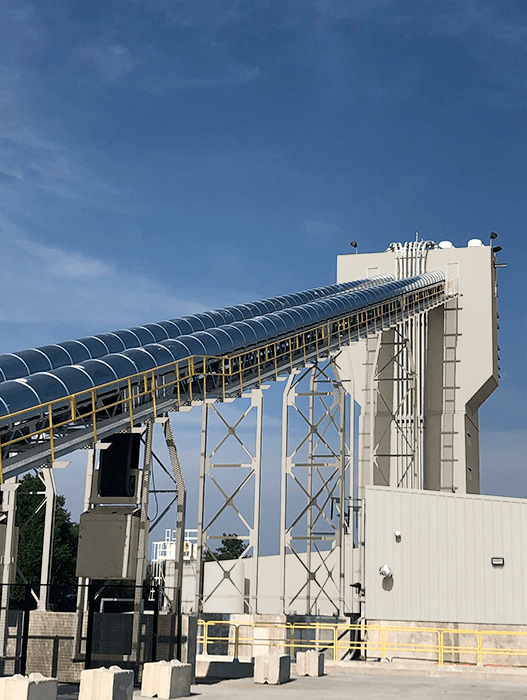

A properly-sized conveyor will ensure that your aggregate supply will keep up with your concrete batch plant’s maximum rated production capacity. Therefore, the capacity and design of your batch plant will largely dictate your material handling conveyor requirements.

Astec has helped numerous producers of concrete and aggregate products find the right material handling system for their needs. Astec offers a wide range of material handling systems for new batch plants, as well as for replacement purposes.

Material handling systems can be customized for your new or existing batch plant. Width and speed of belt, hoppers, walkways, covers and other accessories can be customized to provide optimum production for your batch plant. In addition, Astec offers automation controls for any new or used conveyor system. Aggregate heating systems are also available.

Astec also offers turnkey installation and inspection services, customized engineering and site layout, startup and maintenance training, and replacement parts such as hoppers, troughing and return idlers, head and tail pulleys and bearings, belts, drives, and belt cleaners.

Applications

-

![]()

Specialty Concrete

Learn MoreNo matter what the application, with an industry-leading concrete product line Astec is ready to help you build a plant to meet your needs.

-

![]()

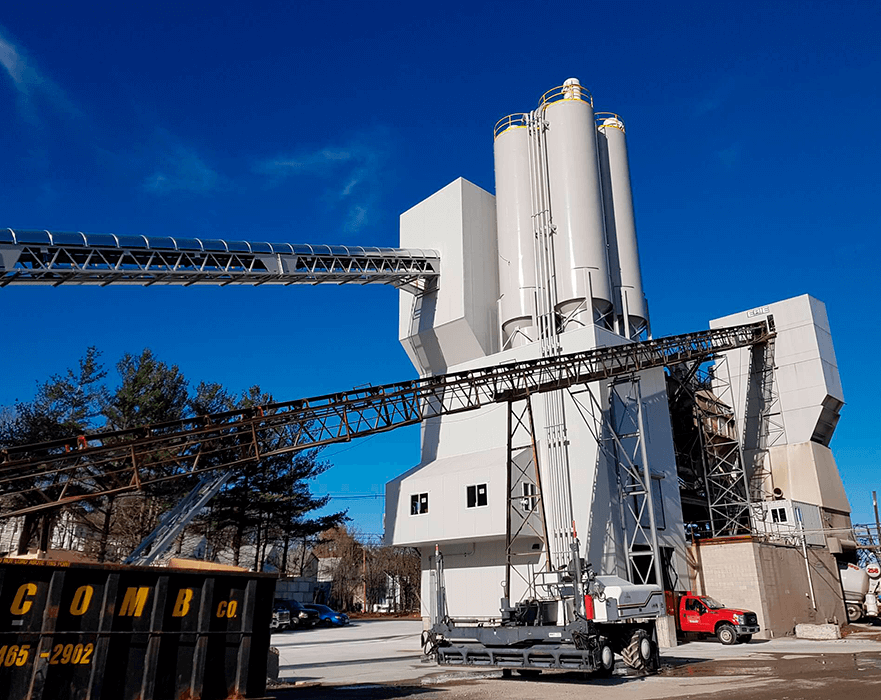

Road Building - Concrete

Learn MoreAstec's comprehensive line of concrete plants delivers high-quality and durability for the roadbuilding industry with an extensive selection of high-production plants and mixers.

-

![Astec BMH EG Dry Batch Concrete Plant]()

Ready Mix Concrete

Learn MoreMany plants in Astec's extensive concrete product line are well-suited to ready mix operations.

-

![Astec BMH custom concrete plant for the precast industry]()

Precast & Prestress

Astec's comprehensive concrete product line features many plants and components for the precast/prestressed concrete market.Learn More