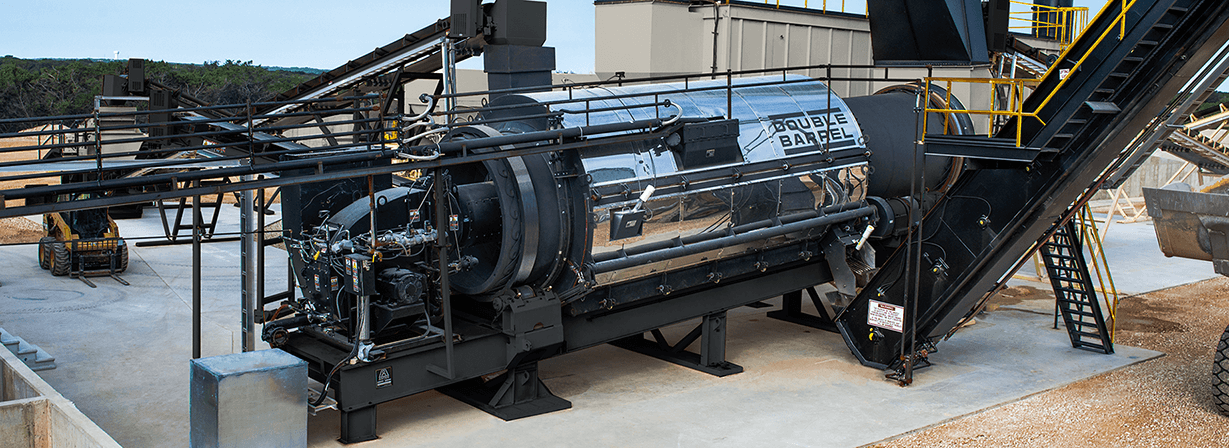

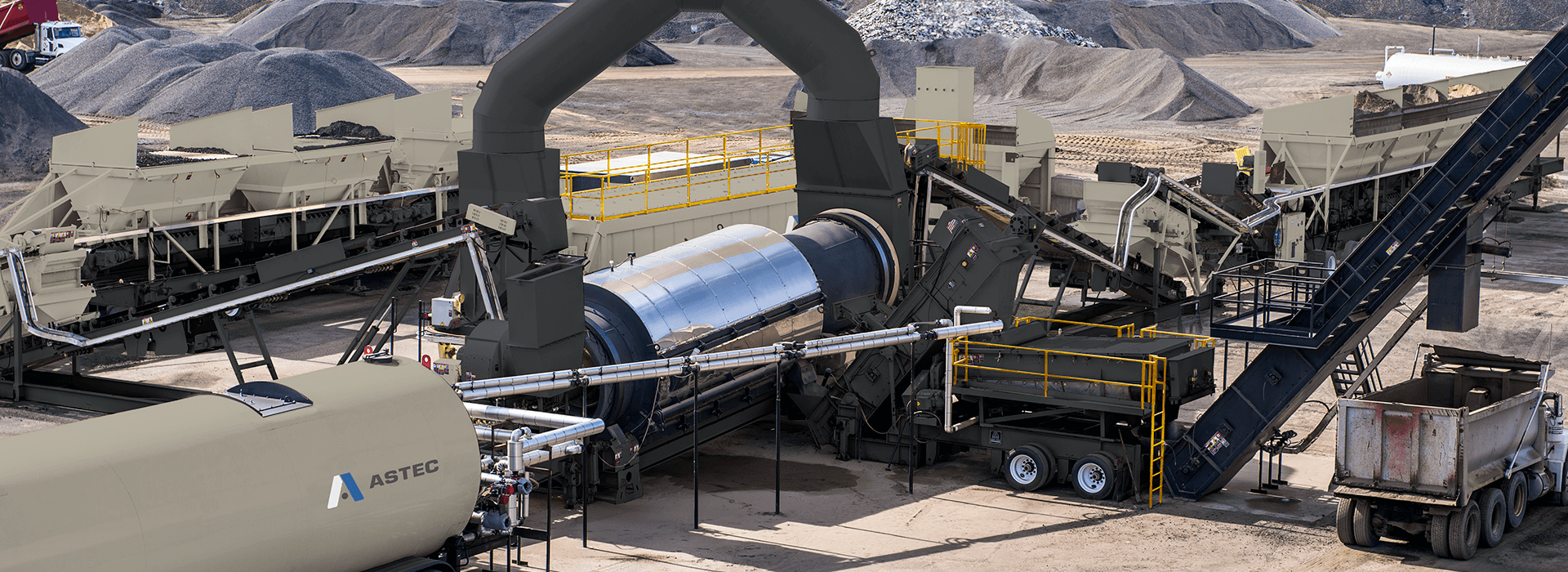

Astec Double Barrel® XHR Drum Mixer

Overview

The Double Barrel XHR system runs mix with up to 65% RAP*

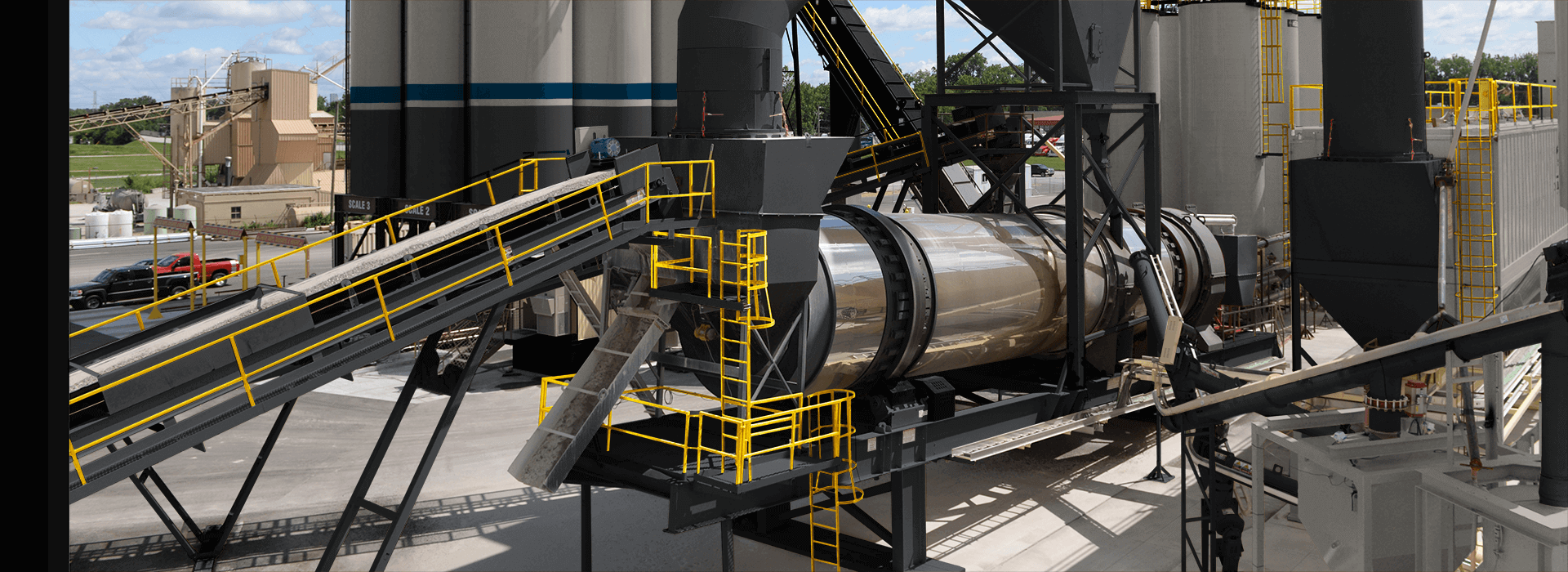

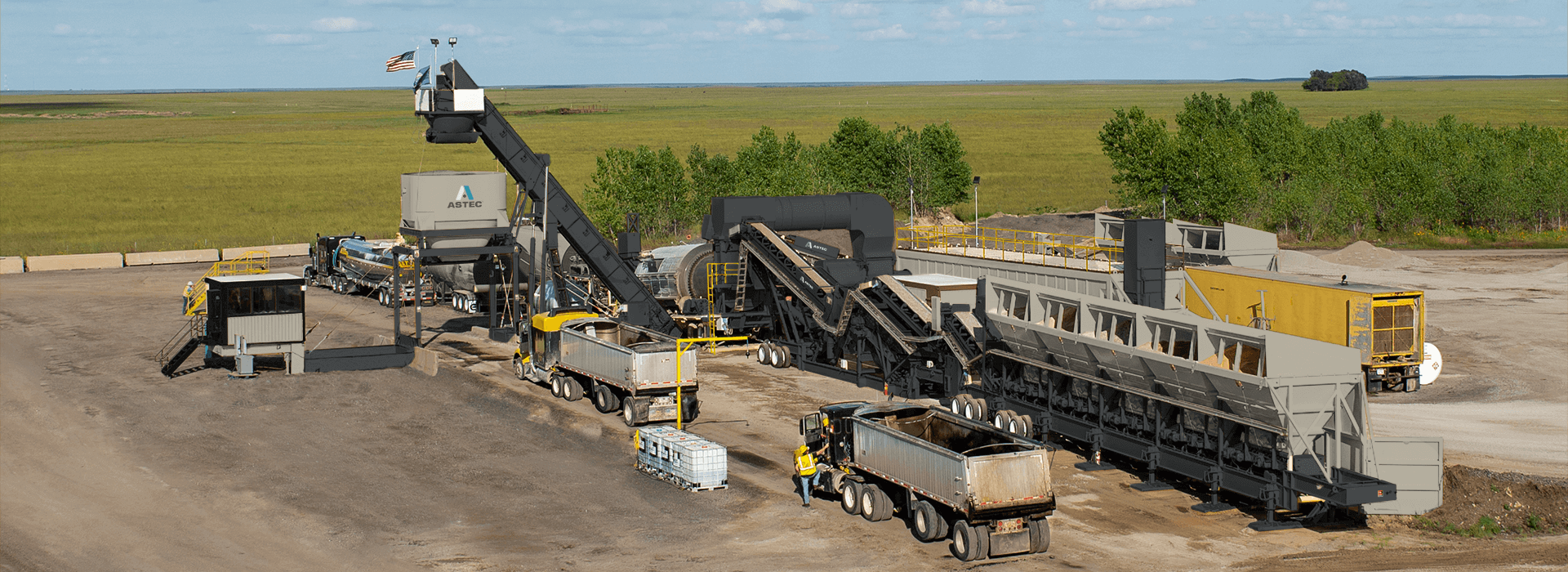

The Astec Double Barrel XHR achieves a quality high RAP mix. To achieve this quality mix, it utilizes both an outer chamber on the drum and an external mixer with the addition of the V-Pac™ Stack Temperature Control System to maintain as low an exhaust temperature as possible when running high RAP content. A stainless-steel drum and stainless-steel combustion flights withstand the higher temperatures associated with running high RAP. The Astec warm mix system comes standard on all Double Barrel XHR mixing systems.

*65% RAP based on 5% RAP moisture

Double Barrel XHR

Applications

-

![]()

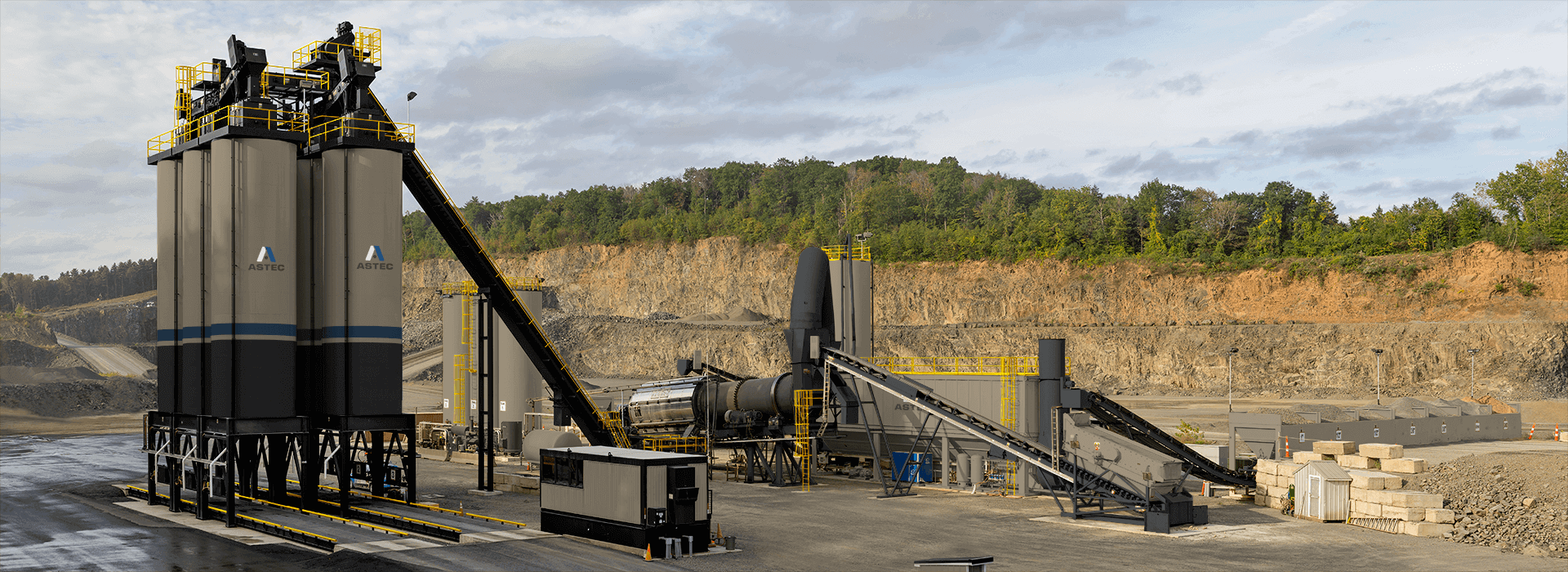

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More -

![]()

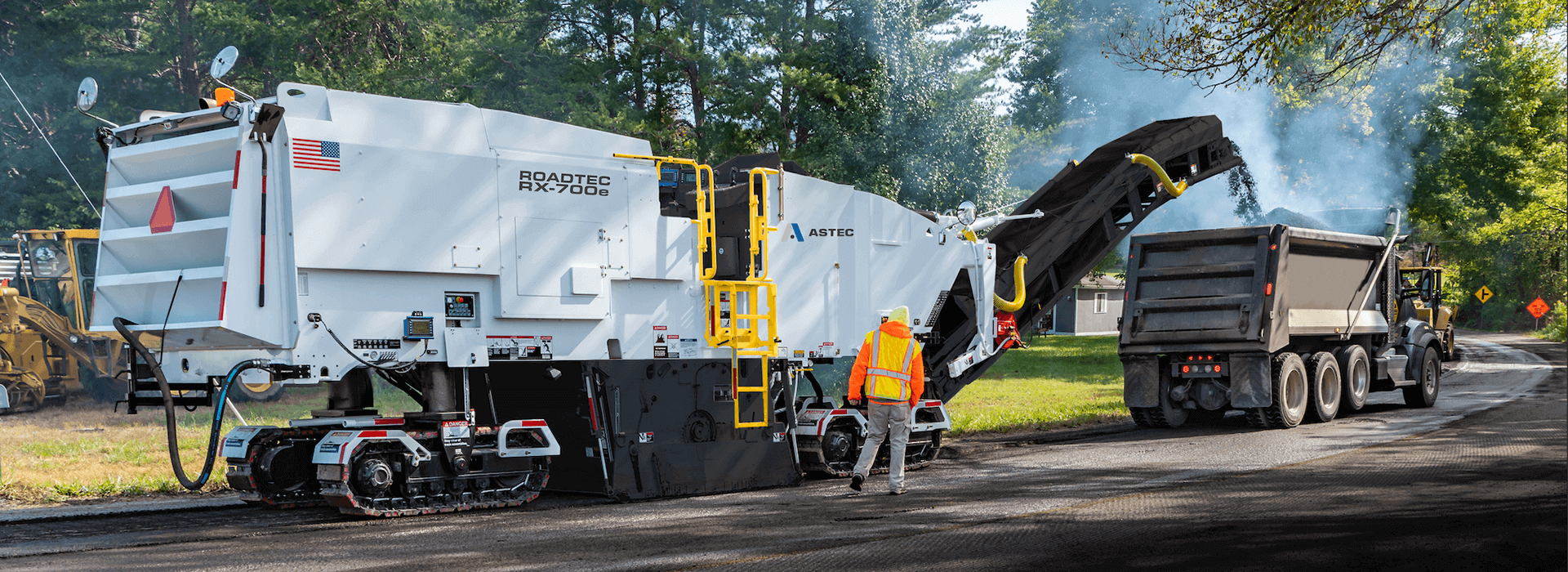

Recycled Asphalt Pavement

Recycled asphalt pavement (RAP) is asphalt paving material recovered from old road beds either by milling or excavation.Learn More

Downloads

Key Specifications

| Drum Size (m) | Mixing Chamber Size (m) | Metric Tons Per Hour (MTPH) |

|---|---|---|

| 1.8 x 13.1 | 5.9 | 181 |

| 2.1 x 14.6 | 5.9 | 272 |

| 2.4 x 15.2 | 6.9 | 362 |

| Drum Size | Mixing Chamber Size | Tons Per Hour |

|---|---|---|

| 6' x 43' | 19' 4.5" | 200 |

| 7' x 48' | 19' 4.5" | 300 |

| 8' x 50' | 22' 10.5" | 400 |

| Drum Size (m) | Mixing Chamber (m) | Metric Tons Per Hour (MTPH) |

|---|---|---|

| 1.8 x 13.1 | 5.9 | 181 |

| 2.1 x 14.6 | 6.8 | 272 |

| 2.4 x 15.2 | 6.9 | 363 |

| 2.7 x 17.3 | 6.9 | 454 |

| 3 x 18.2 | 6.9 | 544 |

| Drum Size | Mixing Chamber | Tons Per Hour |

|---|---|---|

| 6' x 43' | 19' 4.5" | 200 |

| 7' x 48' | 22' 4.5" | 300 |

| 8' x 50' | 22' 10.5" | 400 |

| 9' x 57' | 22' 10.5" | 500 |

| 10' x 60' | 22' 10.5" | 600 |

All specifications subject to change without notice.