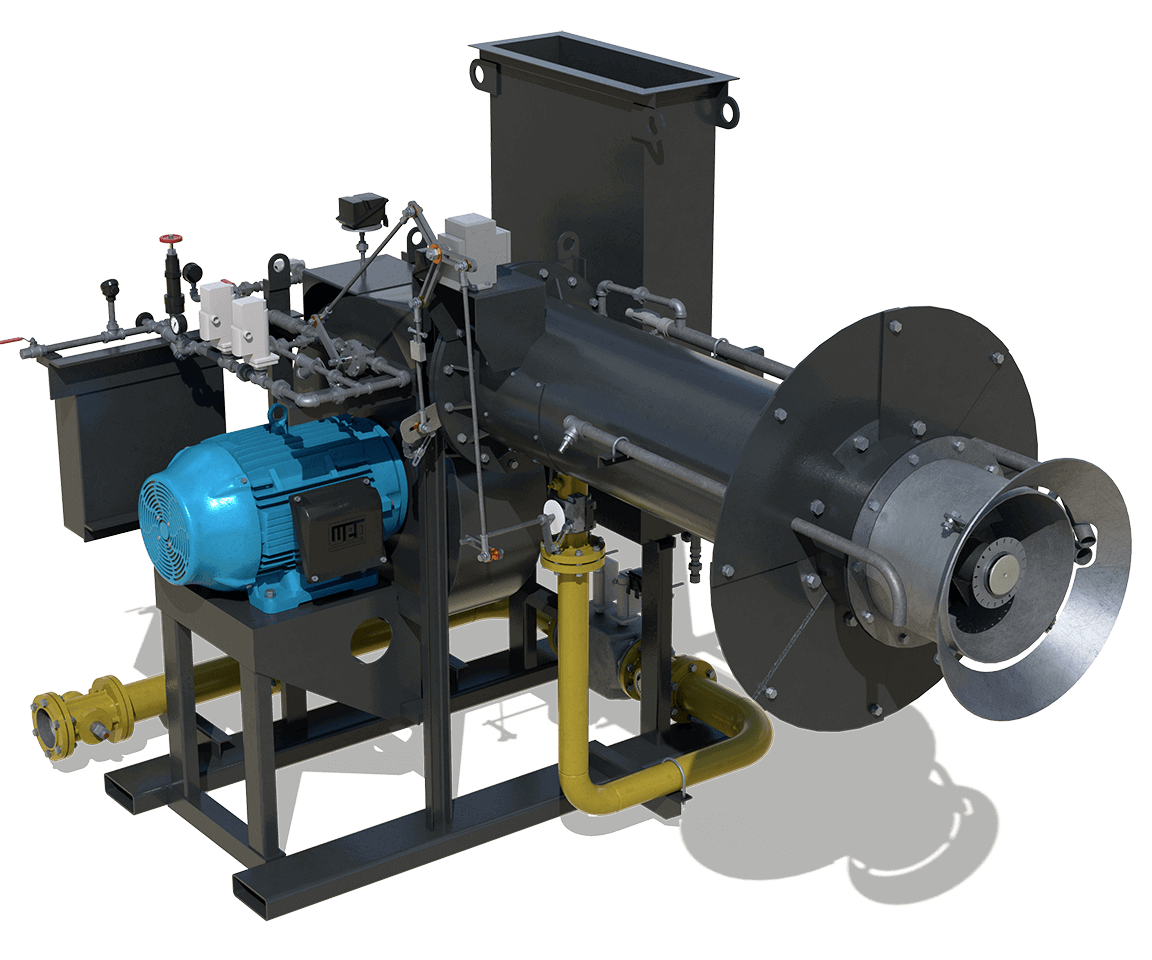

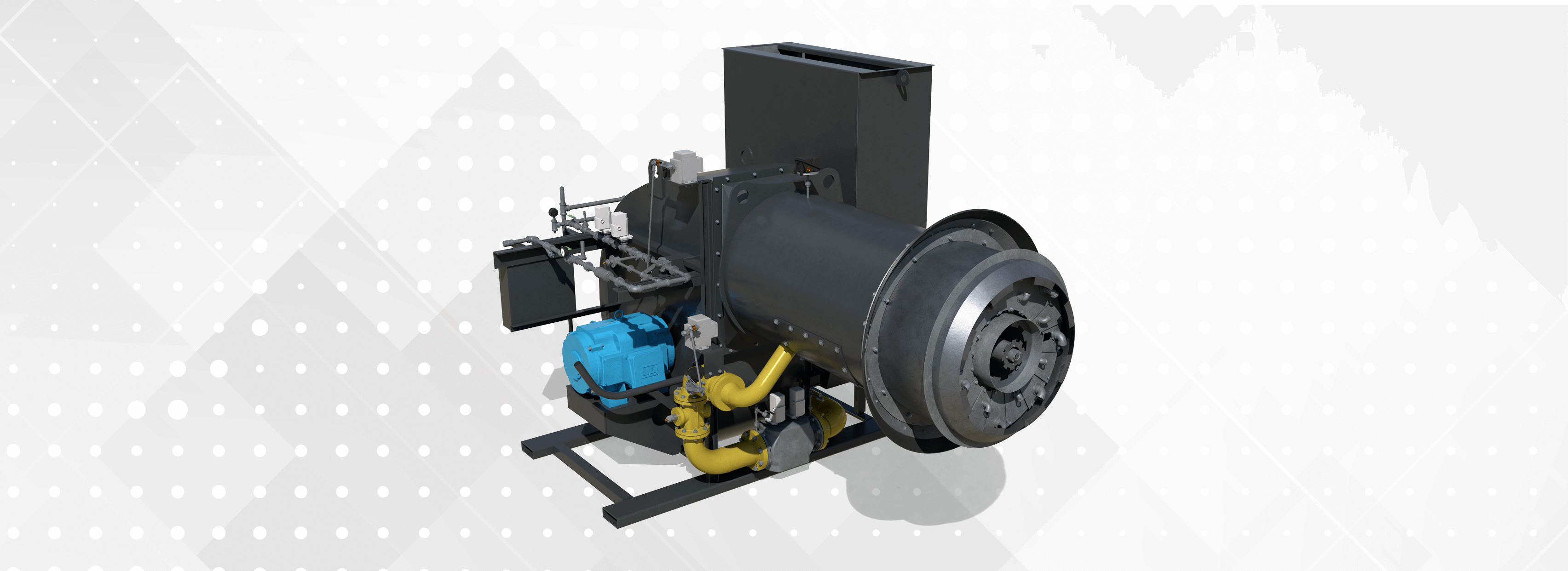

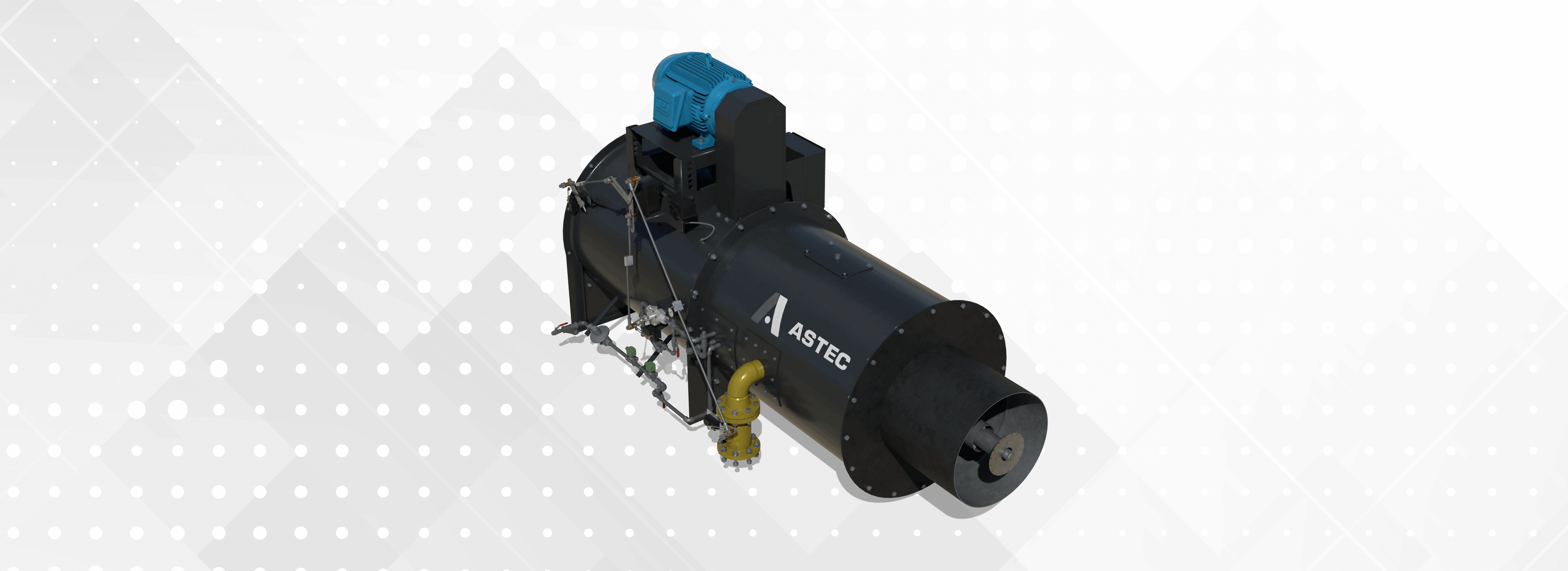

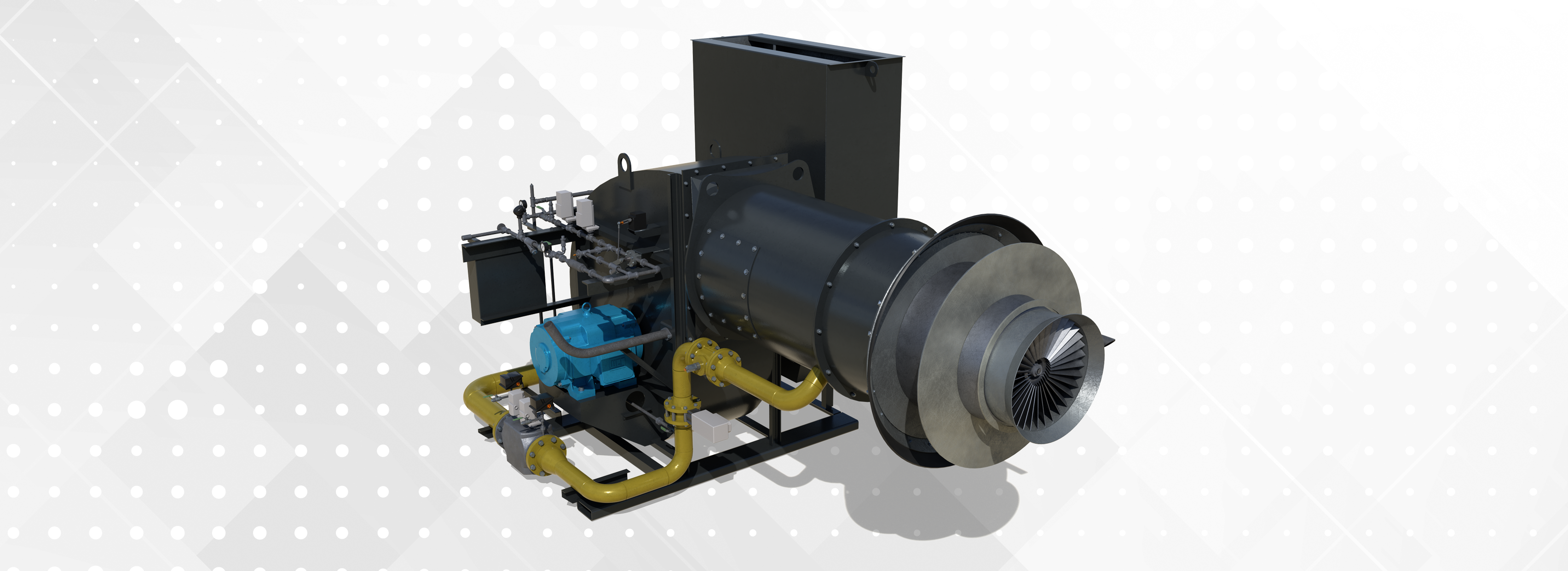

Astec Fury™ Burner

Overview

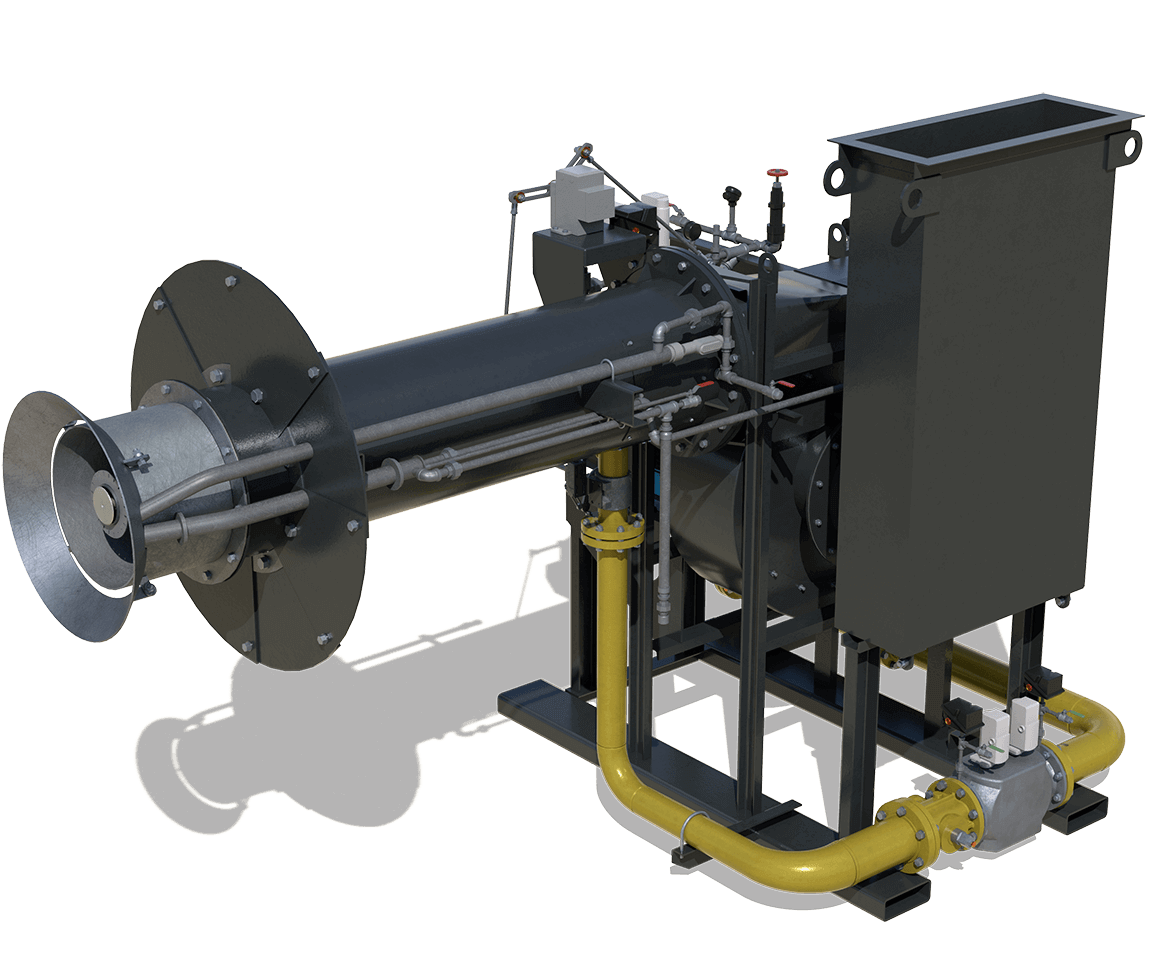

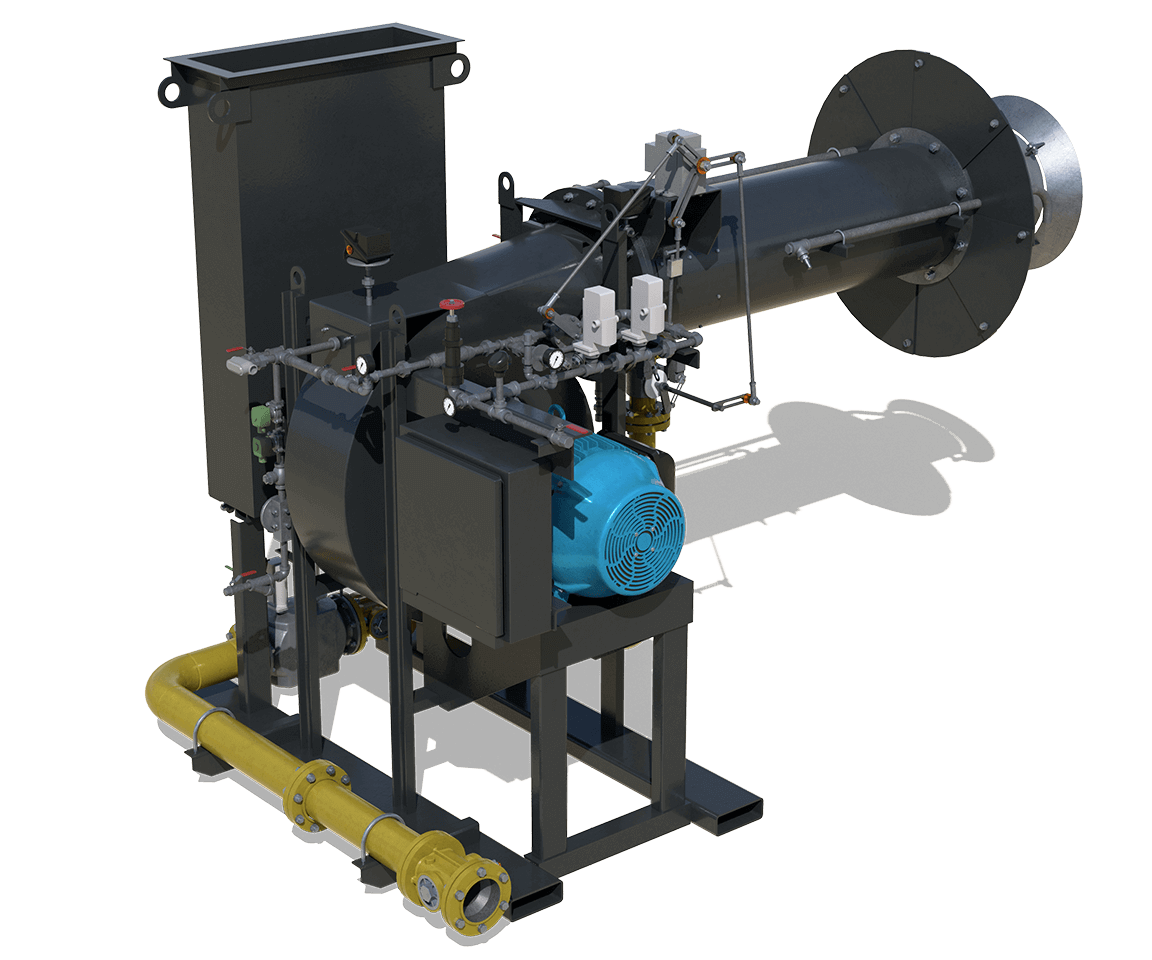

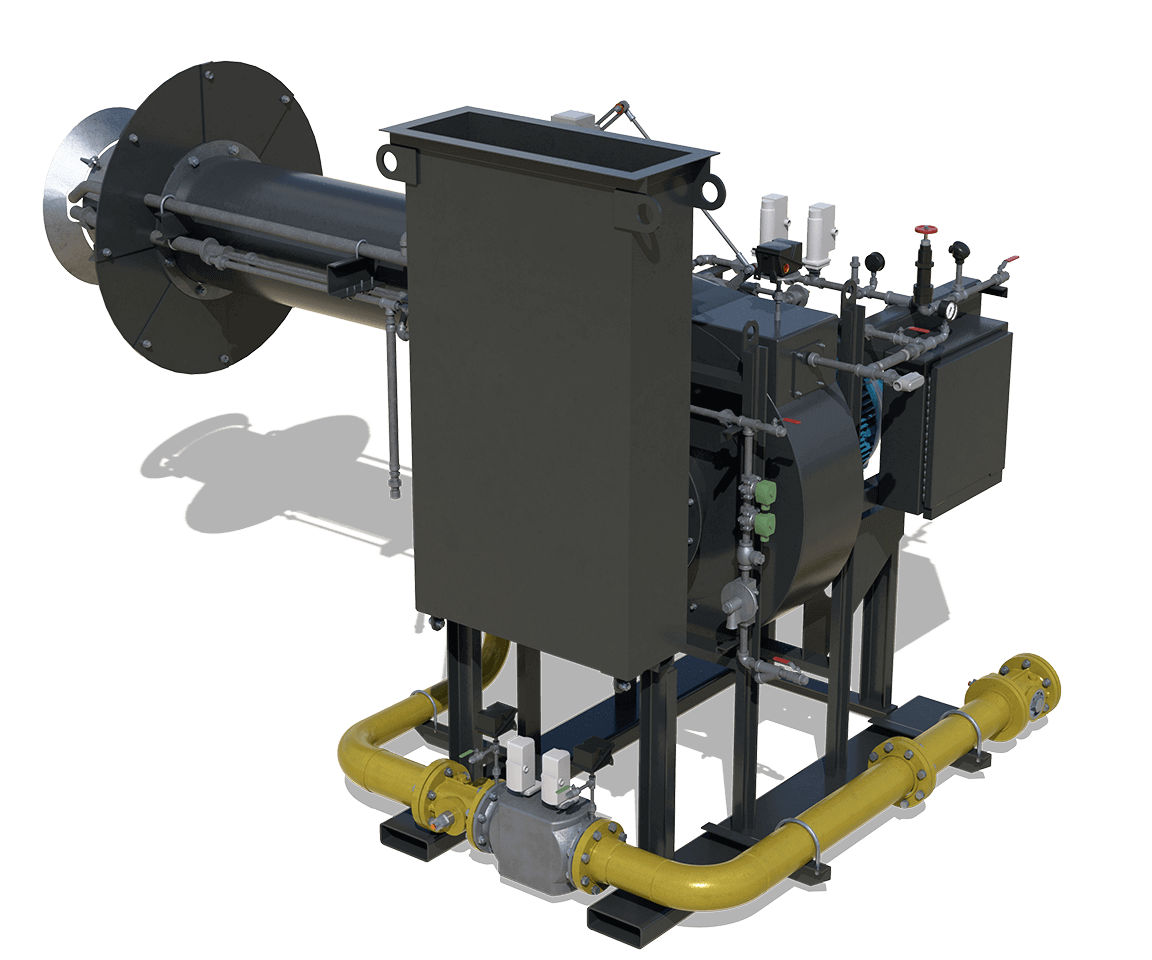

A robust build and simple, accessible construction make the Astec Fury burner a great cost-effective choice.

Compared to other open-fired designs, the Fury burner achieves better emissions and fuel efficiency by putting 50% more combustion air through the burner. The Astec Fury burner is designed to put 50% more combustion air through the burner than competitive designs with the balance of the combustion air drafted in around the burner nose. This means higher combustion quality, better emissions, and higher combustion efficiency throughout the entire firing range.

Rapidly swirling, high-energy air is the key to the Fury burner’s efficient combustion. The swirling air and flame are created by the fixed internal spin vanes, high-pressure blower, and high-velocity nose. The Astec designed pre-filming fuel nozzle uses the combustion air from the high-pressure blower to atomize fuel. This eliminates the need for compressed air at the burner, and helps increase nozzle life. A compact flame makes the Astec Fury burner compatible with virtually all drum designs without complicated drum modifications.

Applications

-

![]()

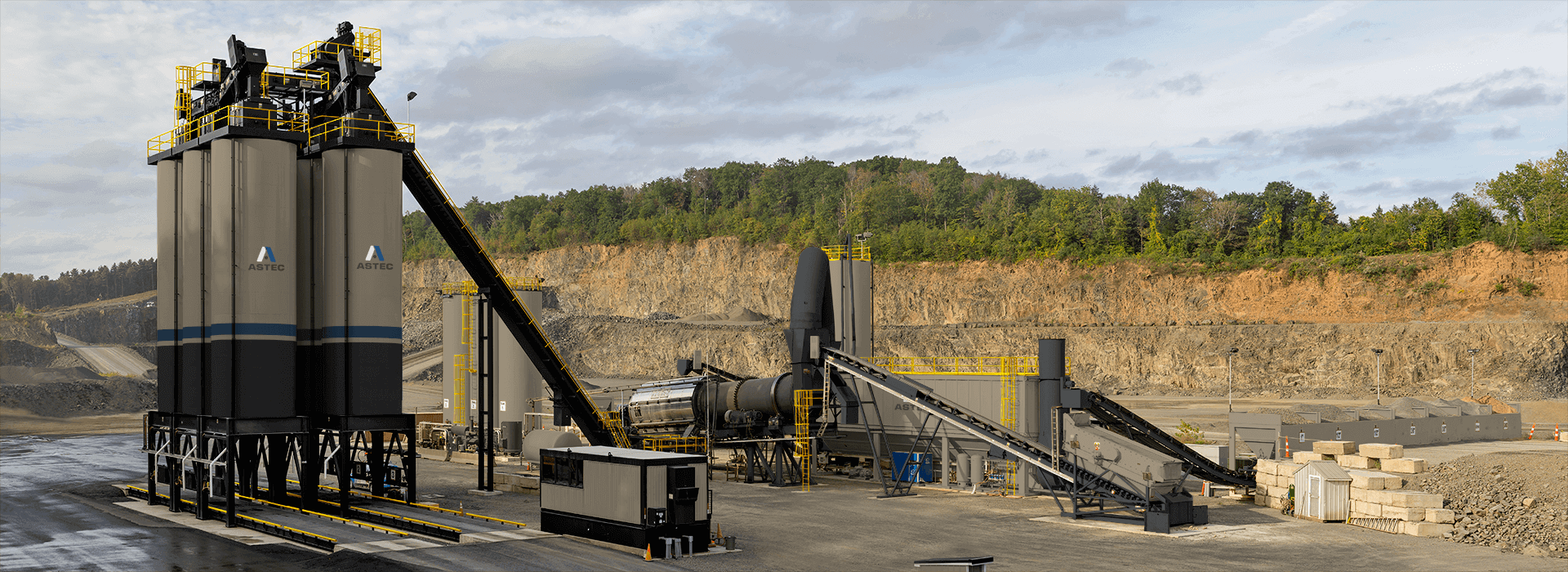

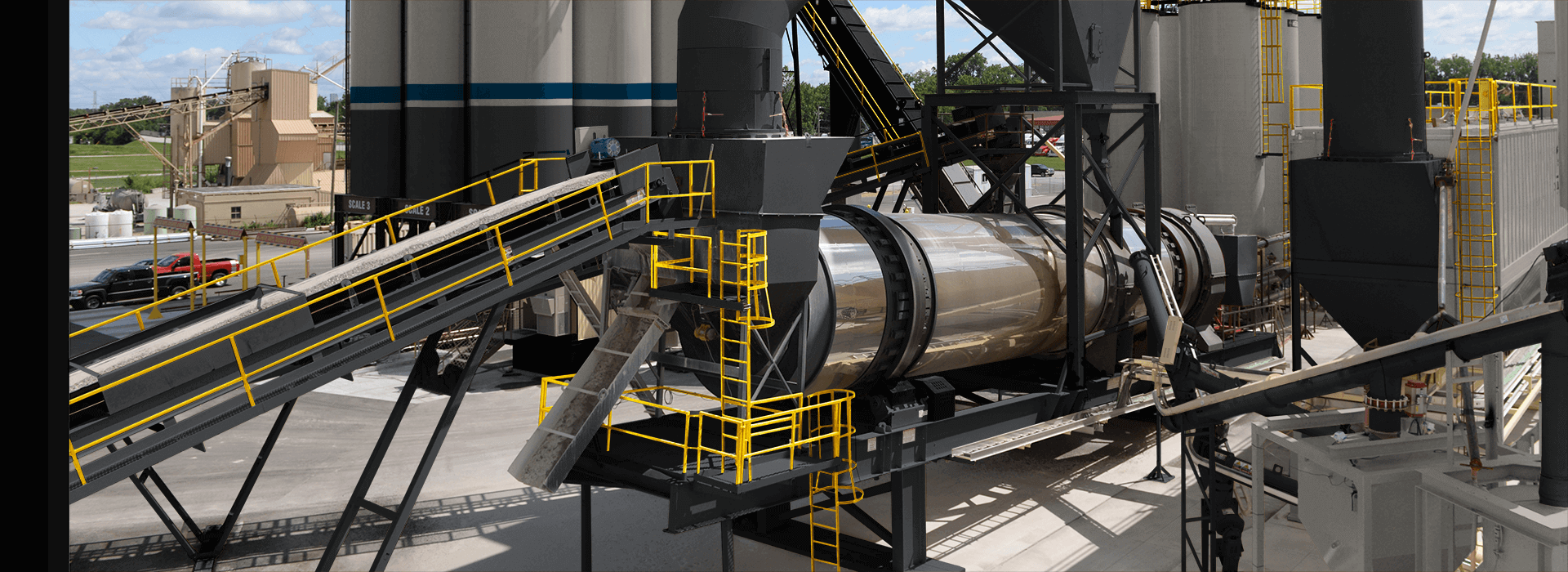

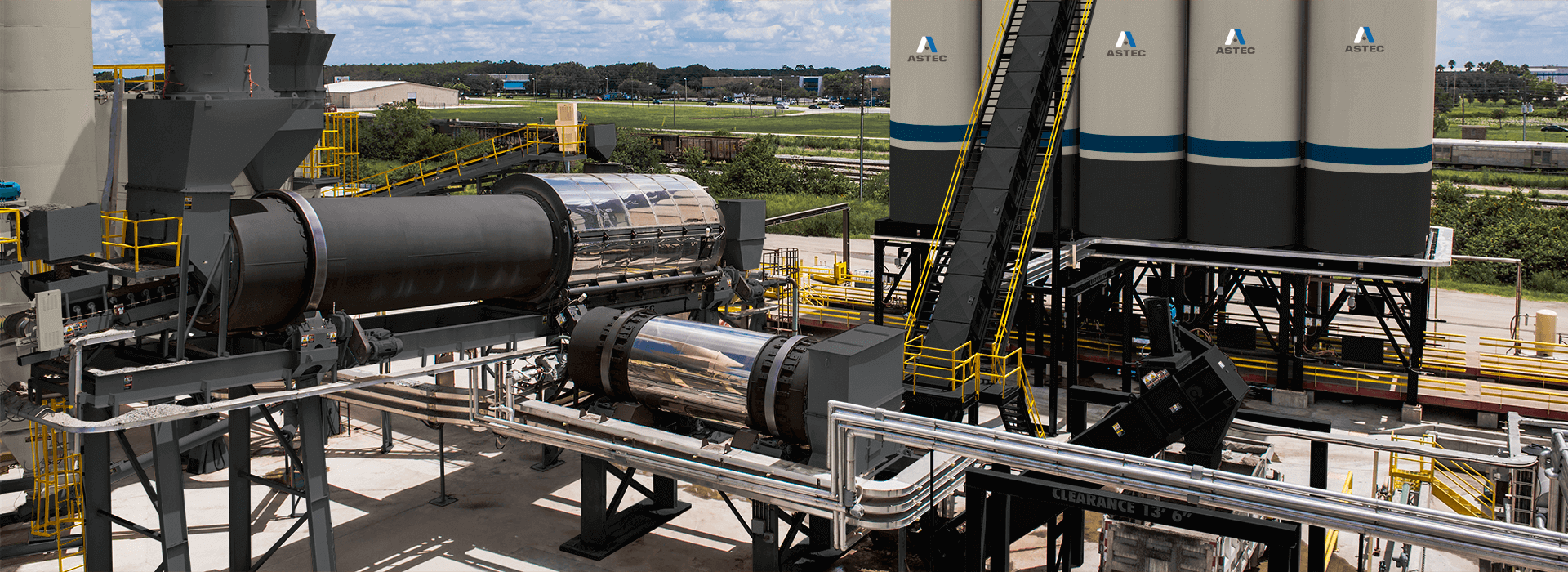

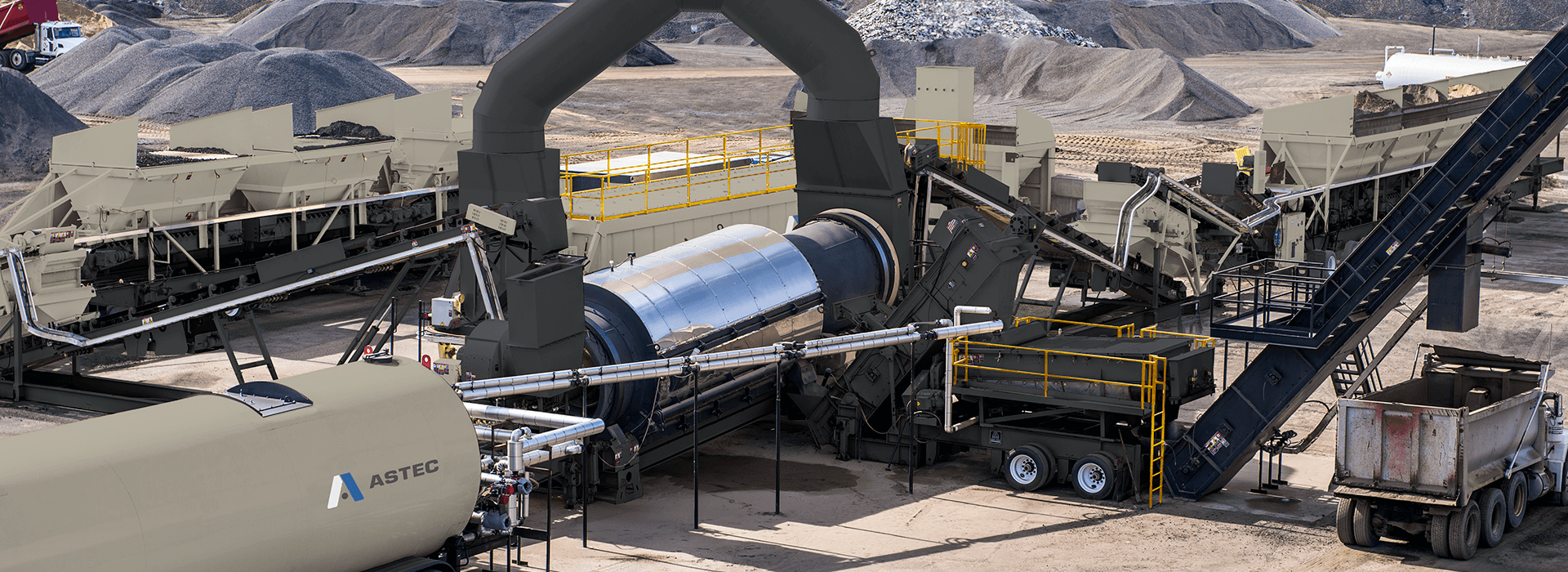

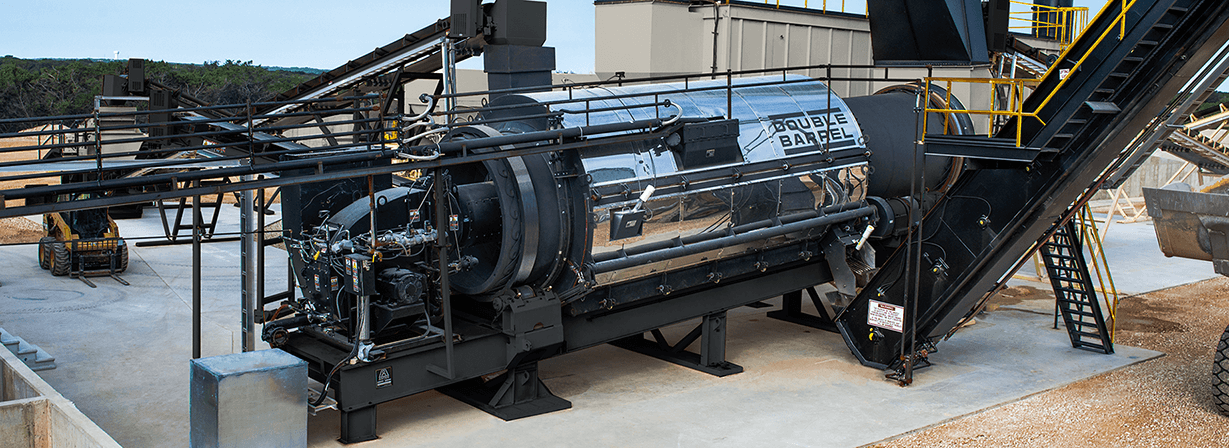

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More

Downloads

Key Specifications

All specifications subject to change without notice.

Above conditions are standard at 75° F at sea level. See detailed capacity, performance sheets for each size for more information and specific flows and pressures. Nominal aggregate drying capacity based on typical exhaust stack temperatures of 240° F, 0.2 BTU/Lbm F specific heat in the aggregate. Burner maximum design capacity is 100% of rated capacity. Advertised numbers are achievable in some conditions, but not guaranteed