Heatec Barracuda® Colloid Mill

Overview

The Heatec Barracuda® Colloid Mill is used to make polymer modified asphalt and emulsified asphalt. It has the ability to produce 15,000* gallons of emulsified asphalt per hour in a single pass through the mill. It is powered by a either a 150 or 75 hp electric motor. The mill is designed so the motors are interchangeable without having to change many of the components in the event that you might need to upgrade to the larger motor for higher production.

Mixing in the mill takes place in the gap between the two mill plates. One plate is mounted on an adjustable stator and remains fixed during operation. The other plate is mounted on the rotor and spins at 3600 rpm. The liquids are combined or polymers are sheared by the action of the plates. The gap between the plates can be adjusted to produce the optimum mixture.

The mill comes as a stand alone unit but can be packaged on a skid with additional equipment to give you a complete system. The skid can be fitted with automated controls, metering package, latex pump, piping and more. The skid makes it easy to install the system. You simply need to attach power and tanks.

Applications

-

![Heatec Fuel Storage Tanks]()

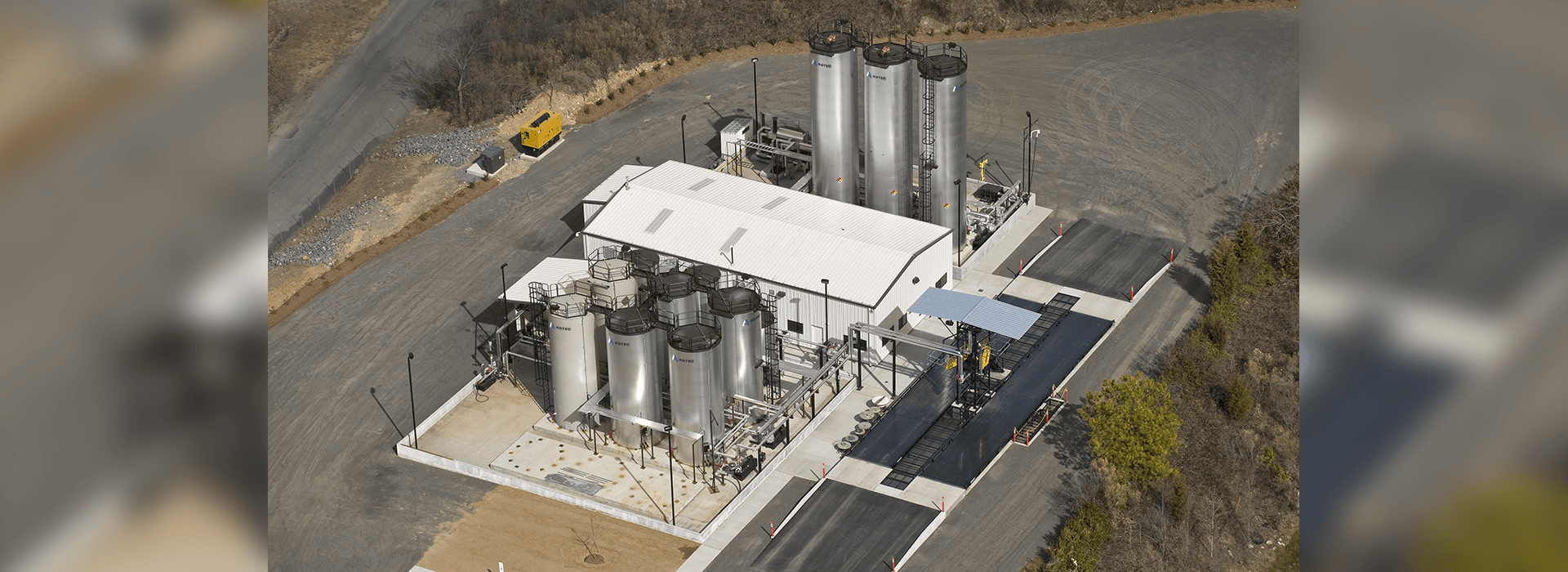

Roofing & Construction Products

Throughout the asphalt/roofing industry efficient heating systems and services are needed as well as reliable storage systems. Astec has an extensive background supplying equipment designed for heating and storing liquid asphalt as well as experience with all types of thermal systems.Learn More -

![]()

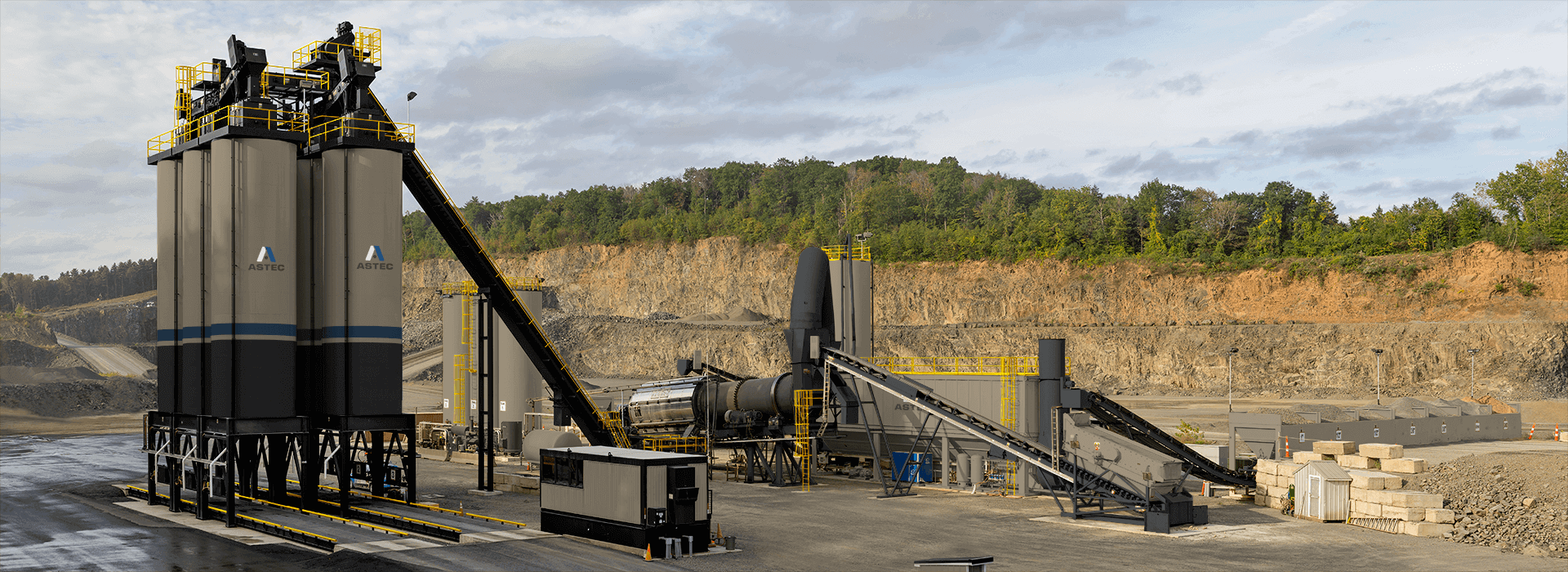

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More