Heatec Barrel Melter

Overview

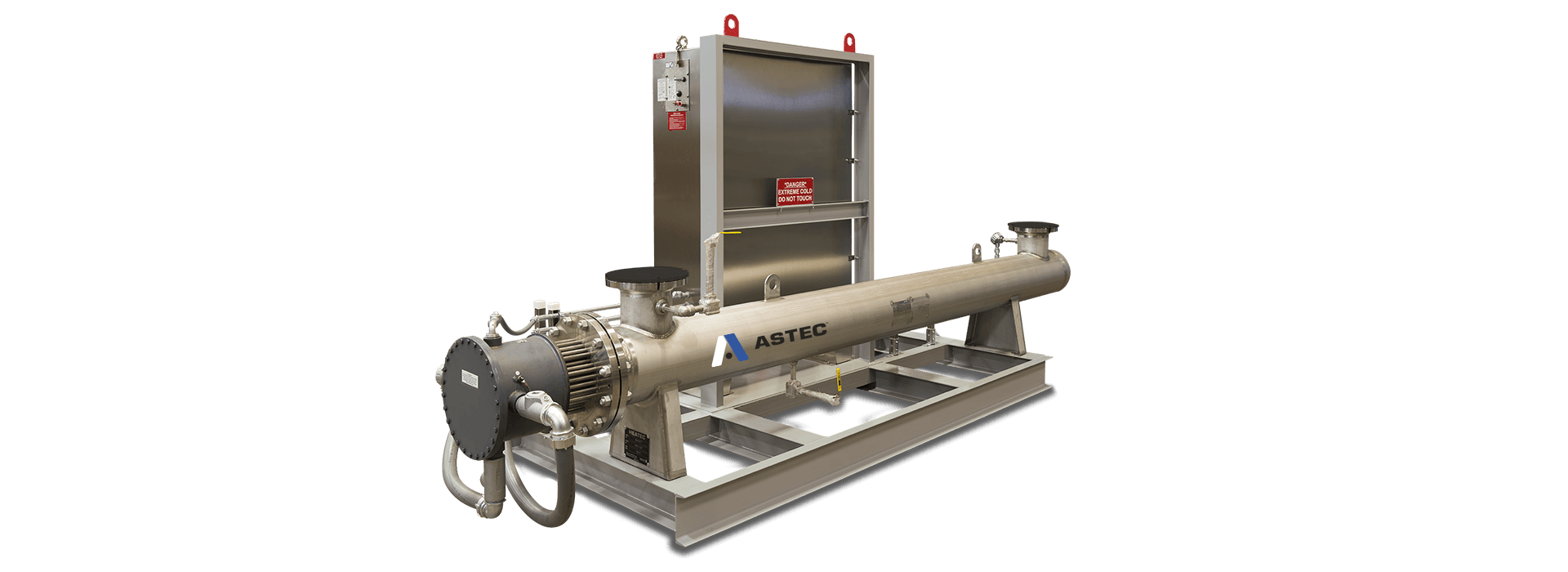

Astec offers two types of melters to change solidified asphalt cement into liquid asphalt cement. One is known as a barrel melter. The other is known as a hot box.

The barrel melter is used at isolated asphalt plants and terminals to melt incoming loads of asphalt shipped in barrels. Isolated plants are usually those at remote locations not served by rail cars or barges.

The barrel melter has a built-in hydraulic crane and internal trolley to handle the barrels and place them atop or into the unit. Heat is applied to the barrels causing the asphalt to drop as a slug into the insulated tank of the unit where the asphalt is heated to mix temperature.

The barrel melter includes a thermal fluid heater that provides hot oil for the coils that heat the tank. The unit also includes a pump system to transfer the liquid cement to other equipment for storage. It has a capacity of 30 drums per hour.

Other variations are offered, such as stationary units that uses an existing thermal fluid heater if one is available.

The hot box is used at asphalt terminals and emulsion plants to re-melt

buckets of asphalt that have been collected from drippings and samples

used for testing. It is heated by the plant’s hot oil system.

Applications

-

![]()

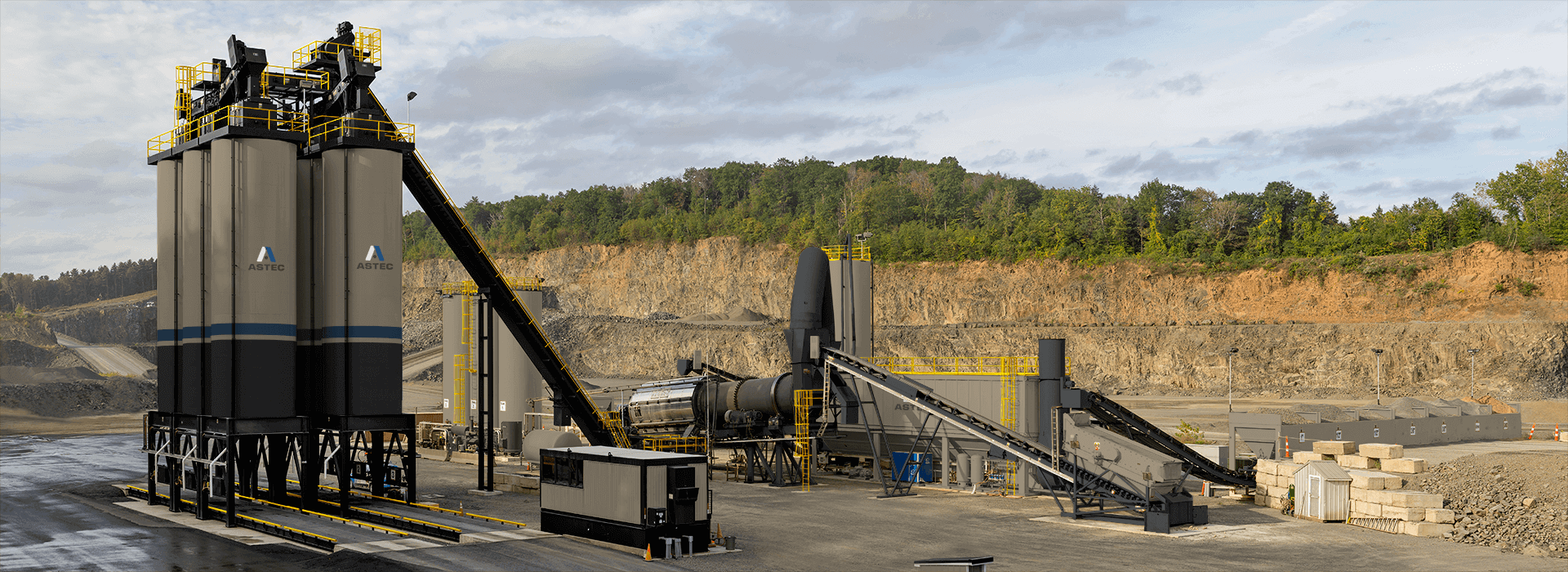

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More -

![Heatec Fuel Storage Tanks]()

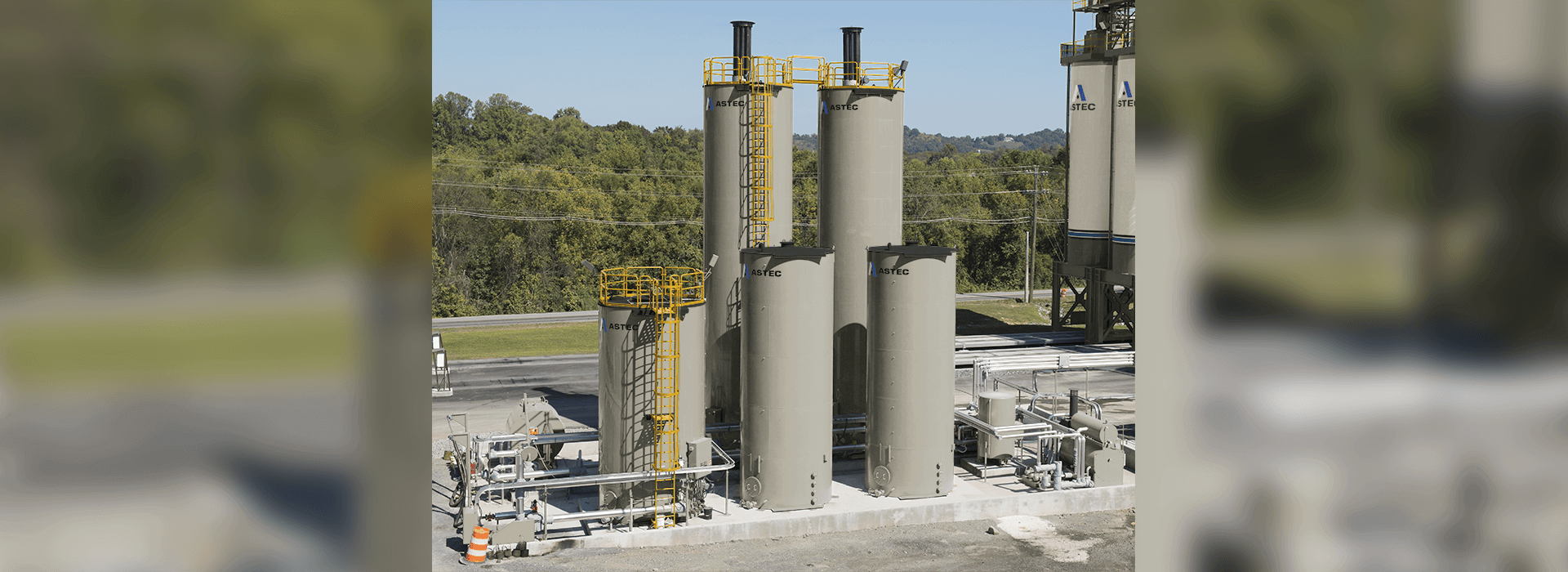

Roofing & Construction Products

Throughout the asphalt/roofing industry efficient heating systems and services are needed as well as reliable storage systems. Astec has an extensive background supplying equipment designed for heating and storing liquid asphalt as well as experience with all types of thermal systems.Learn More