Heatec Steam Generator

Overview

Heatec steam generators eliminate the need for a boiler. They produce steam by heating water with hot thermal fluid from a thermal fluid heater. The hot thermal fluid circulates through tubes of the steam generator, heating water surrounding the tubes and converting it into steam.

Steam generators have significant advantages over boilers. Tubes in the steam generator never get hotter than the thermal fluid flowing through them. This minimizes explosion hazards associated with boilers. And because steam generators are not fired, they are not subject to restrictions for fired boilers. Steam generators do not require a boiler operator, who (in most states) must be present whenever a boiler is in operation.

Steam is used for temporary heating hookups where use of hot oil is not practical. For example, steam is used at asphalt terminals to heat tank cars filled with asphalt so they can be unloaded.

Applications

-

![]()

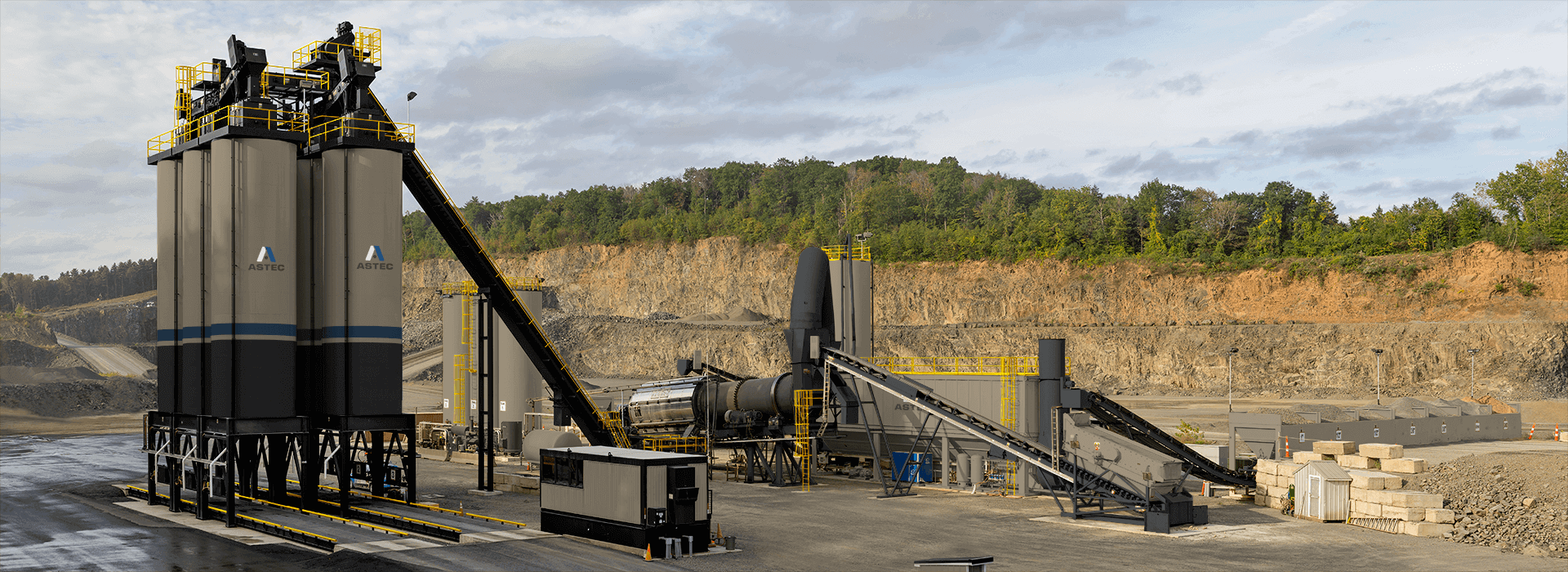

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More -

![Heatec HCI Heater]()

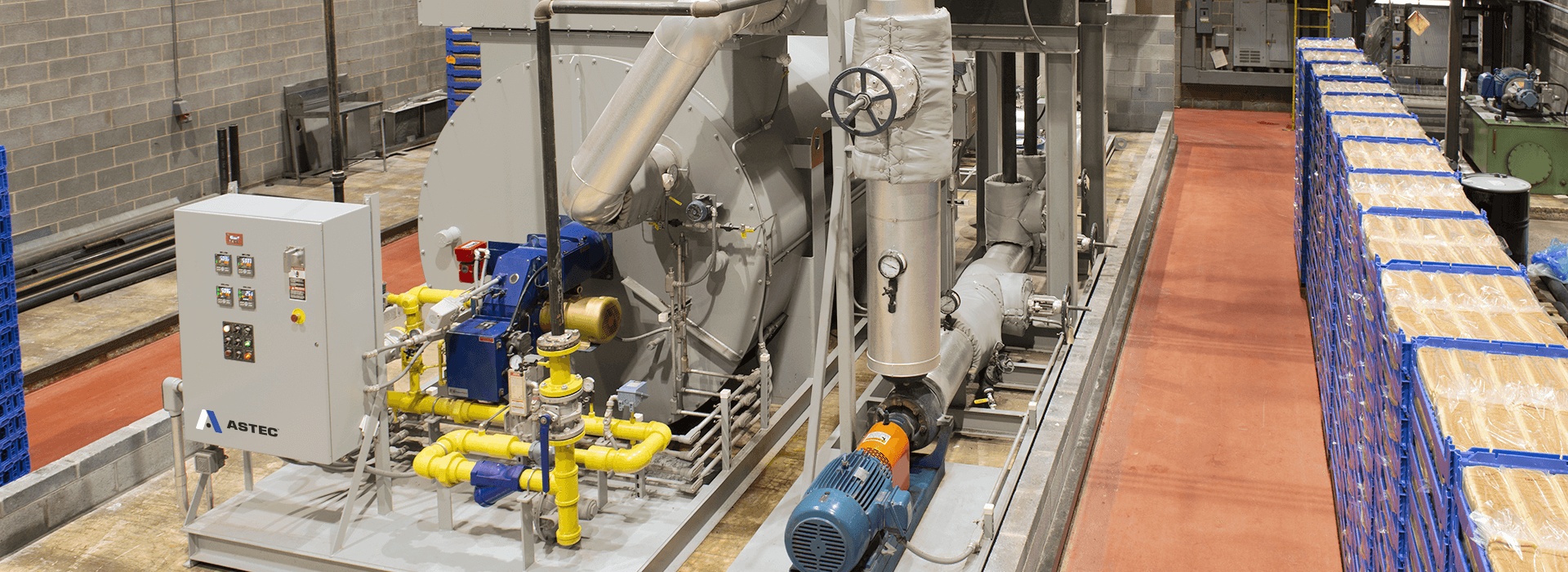

Food & Beverage Production

Large-scale, commercial food and beverage production relies on thermal processing techniques to ensure the safety of consumables. Reliable and efficient systems are critical to ensure safe food and beverage production. Astec has extensive experience with supplying systems for large-scale food and beverage production.Learn More -

![Heatec Fuel Storage Tanks]()

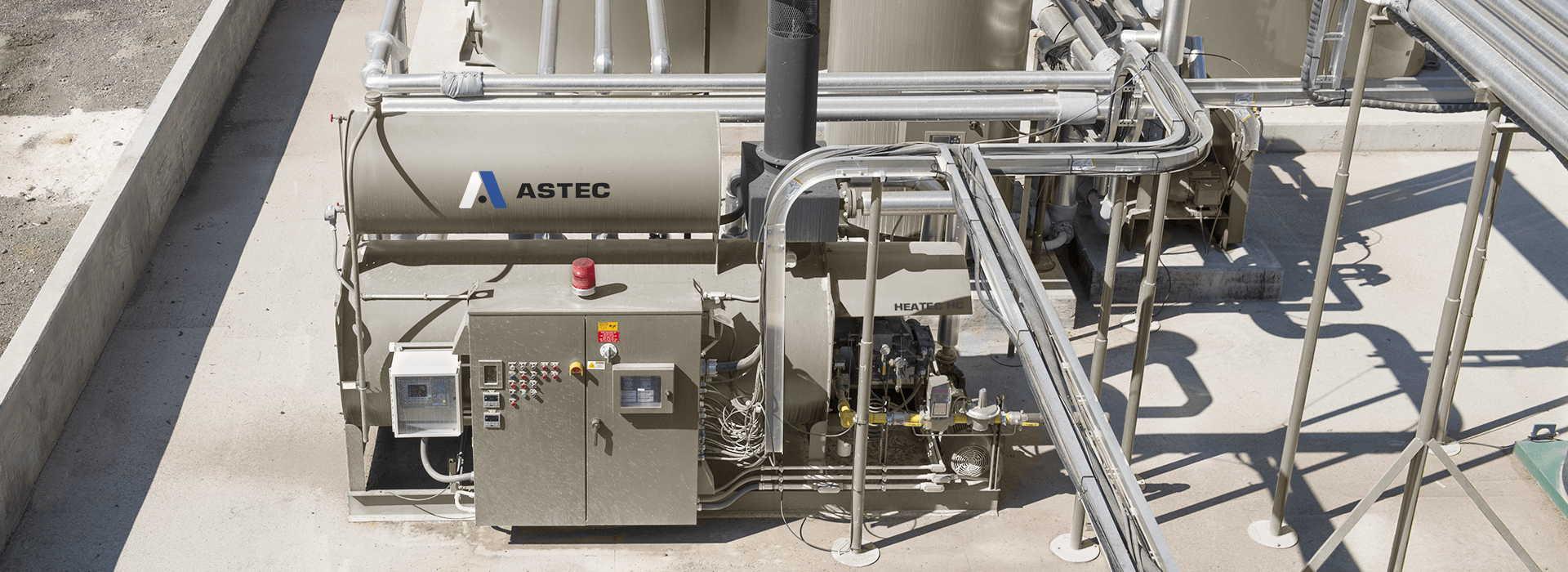

Roofing & Construction Products

Throughout the asphalt/roofing industry efficient heating systems and services are needed as well as reliable storage systems. Astec has an extensive background supplying equipment designed for heating and storing liquid asphalt as well as experience with all types of thermal systems.Learn More