Peterson 6710D Horizontal Grinder

Overview

The 6710D Horizontal Grinder is Peterson’s largest grinder, and is designed for operations that need the most durable, highest output machine.

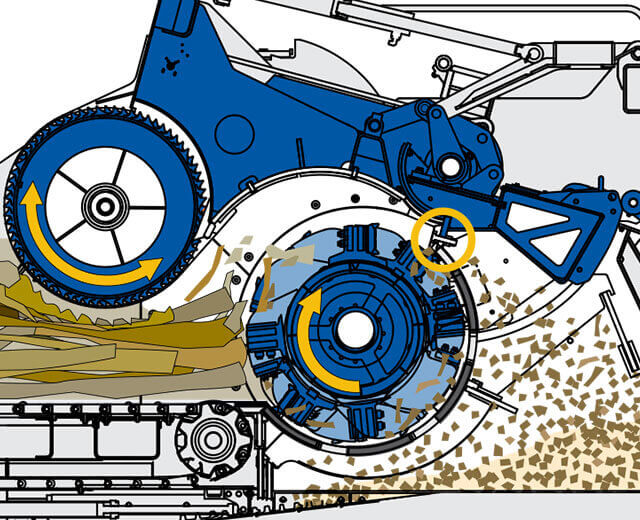

Powered by a 1125hp (839 Kw) Tier IV, Caterpillar C32 engine (or an export only Tier II engine), the 6710D is designed for the toughest jobs. With a feed opening of 50 x 66 inches (127 x 168 cm), the 6710D can even process large stumps that used to be reserved for tub grinders. The grinder is particularly suited for land clearing operations or other applications where mobility is desired. Track mounting also reduces material handling costs in conventional recycling yards as well.

Applications

-

![]()

Compost

Compost is decomposed organic matter derived from either a single source material or blended for specific application performance. Materials can include garden debris, kitchen scraps, manure or yard and lawn waste.Learn More -

![]()

Orchard Clearout

Commercial orchards are cleared on a rotating cycle to remove lower producing or unhealthy deciduous fruit, citrus and nut trees or to replace them with a more valuable crop. New, higher-producing trees are replanted so the cycle can start again.Learn More -

![]()

Municipal Solid Waste (MSW) Recycling

Municipal solid waste (MSW) consists of everyday items we use and then throw away, such as product packaging, furniture, clothing, bottles, food scraps and newspapers. These items come from our homes, schools, businesses, etc.Learn More -

![]()

Organic Recycling

Green waste recycling is fresh or biodegradable waste material including grass, leaves, plants and tree trimmings that can be diverted from landfills for recycling. This method is best used to produce compost for use on gardens, lawns, erosion control projects and agricultural crops.Learn More -

![]()

Natural Disaster Cleanup

Natural disasters such as hurricanes, tornadoes, earthquakes, fires or floods create debris that must be cleared to restore affected areas. This type of debris can be green waste (such as tree limbs), furniture, drywall or entire structures that have to be demolished and recycled.Learn More -

![]()

Construction & Demolition Recycling

Construction and demolition recycling (C&D) is mixed material associated with construction and demolition. The material could include wood, cardboard, gypsum, plastic, metal, wire, roofing shingles, asphalt, concrete and more. By separating and recycling different materials it reduces landfill waste and associated costs, while also producing value-added products.Learn More -

![]()

Wood Waste Recycling

Wood waste is the second largest category of construction and demolition (C&D) debris, and accounts for 10% of material added to landfills annually.Learn More -

![]()

Railroad Tie Recycling

The creosote treated railroad ties are a valuable energy source, once they have been broken down into a manageable and consistent size.Learn More -

![]()

Mulch

Organic mulch is a product that can decompose, providing nutrients to the soil over time. It can be made from a variety of materials, typically organic, but not exclusively.Learn More -

![]()

Land Clearing

Learn MoreLand clearing generally consists of trees, limbs and roots cleared from forested or partially forested land that will be used for a new purpose including farming, commercial development or right-of-ways.

-

![]()

Biomass

Biomass is an energy source derived from renewable and sustainable organic materials to create electricity or other forms of power. Horizontal grinders and drum chippers are highly productive machines for creating biomass.Learn More -

![]()

Asphalt Shingle Recycling

Asphalt shingle grinding is the process of making recycled asphalt shingles (RAS). RAS is produced by grinding asphalt roofing shingles to a small spec, generally under 3/8” to salvage the valuable asphalt and sand.Learn More

Downloads

Key Specifications

| Dimensions | Specifications |

|---|---|

| Operating Length | 1857 cm |

| Operating Width | 374 cm |

| Operating Height | 515 cm |

| Travel Width | 364 cm |

| Travel Length | 1493 cm |

| Travel Height | 338 cm |

| Frame Length | 1336 cm |

| Front Angle of Approach | 10º |

| Rear Angle of Approach | 20° |

| Ground Clearance | 46 cm |

| Dimensions | Specifications |

|---|---|

| Operating Length | 60' 11" |

| Operating Width | 12' 3" |

| Operating Height | 16' 11" |

| Travel Width | 12' 0" |

| Travel Length | 49' 0" |

| Travel Height | 11' 1" |

| Frame Length | 43' 10" |

| Front Angle of Approach | 10º |

| Rear Angle of Approach | 20° |

| Ground Clearance | 18" |

| Weights | Specifications |

|---|---|

| Machine Weight | 48,987 kg |

| Specifications | Specifications |

|---|---|

| 108,500 lbs | 48,987 kg |

| Powertrain | |

|---|---|

| Engine | Caterpillar C32 Tier IV, 839 kW Caterpillar C32 Tier II, 839 kW export only |

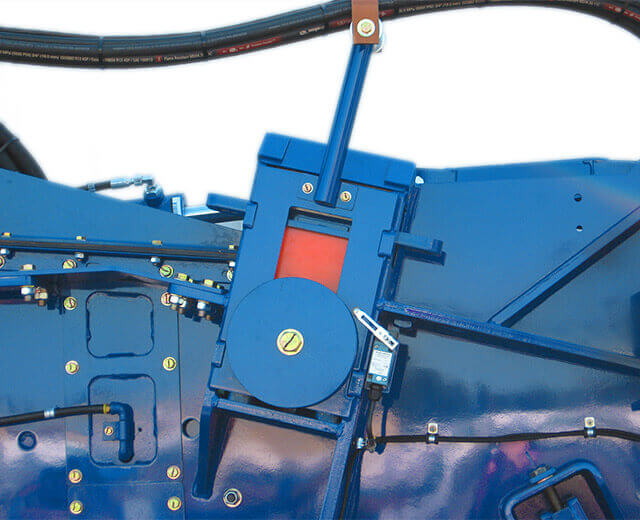

| Clutch | PT Tech HPT015FX |

| Fuel Tank Capacity | 1567 L |

| Main Hydraulic Tank Capacity | 360 L |

| System Controls | |

| Adaptive Control System | Checkmark |

| Radio Remote | Checkmark |

| Peterson+ Analytics | Checkmark |

| Powertrain | |

|---|---|

| Engine | Caterpillar C32 Tier IV, 1125 hp Caterpillar C32 Tier II, 1125 hp export only |

| Clutch | PT Tech HPT015FX |

| Fuel Tank Capacity | 414 gal |

| Main Hydraulic Tank Capacity | 95 gal |

| System Controls | |

| Adaptive Control System | Checkmark |

| Radio Remote | Checkmark |

| Peterson+ Analytics | Checkmark |

| Tracks | Specifications |

|---|---|

| Track Type & Width | triple grouser, 71 cm |

| Travel Speed | 1.6/2.7 kph |

| Track Length | 495 cm |

| Front to Track Length | 528 cm |

| Tracks | Specifications |

|---|---|

| Track Type & Width | triple grouser, 28" |

| Travel Speed | 1.0/1.7 mph |

| Ground Pressure | 12.1 lbs/in² |

| Track Length | 16' 3" |

| Front to Track Length | 17'3" |

| Feed System | Specification | |

|---|---|---|

| Feed Opening (w x h) | 168 x 127 cm | |

| Hopper Width | 168 cm | |

| Feed Conveyor Width | 168 cm | |

| Feed Chain | 5 sections, full hopper width | |

| Compression Roll Diameter | 107 cm | |

| Land Clearing Mode | 168 x 165 cm |

| Feed System | Specification |

|---|---|

| Feed Opening (w x h) | 66" x 50" |

| Hopper Width | 66" |

| Feed Conveyor Width | 66" |

| Feed Chain | 5 sections, full hopper width |

| Compression Roll Diameter | 42" |

| Land Clearing Mode | 66" x 65" |

| Discharge | Specifications |

|---|---|

| Discharge Conveyor Width | 152 cm |

| Discharge Conveyor Height | 511 cm |

| Conveyor Speed | 152,183, or 213 mpm |

| Discharge | Specifications |

|---|---|

| Discharge Conveyor Width | 60" |

| Discharge Conveyor Height | 16' 9" |

| Conveyor Speed | 500, 600, or 700 fpm |

| Production | Volume | Weight |

|---|---|---|

| Greenwaste | 446 m3 | 154 tonnes |

| Scrap Board | 499 m3 | 101 tonnes |

*Actual production output may vary due to moisture content, material density and size, support equipment, grate size, and equipment options. Production rates are based on operating 50 minutes per hour with the standard diesel engine.

| Production | Volume | Weight |

|---|---|---|

| Greenwaste | 583 yd³ | 170 tons |

| Scrap Board | 653 yd³ | 111 tons |

*Actual production output may vary due to moisture content, material density and size, support equipment, grate size, and equipment options. Production rates are based on operating 50 minutes per hour with the standard diesel engine.

| Options | 6710D |

|---|---|

| Magnetic Head Pulley | Checkmark |

| LED work Lights | Checkmark |

| Dust Control | Checkmark |

| Crossbelt Magnet | Checkmark |

| Scrap Metal collection box | Checkmark |

| Export kit | Checkmark |

| CE Certification | Checkmark |

| Feed Tailgate | Not applicable |

| Cold Weather Kit | Checkmark |

| Air Compressor | Checkmark |

| R+ Package | Checkmark |

| ASG Package | Not applicable |

| Flat Feed Deck | Not applicable |

| Liquid Injection System | Not applicable |

| Tow Dolly | Not applicable |

| Extra-Long Discharge Conveyor | Not applicable |

| Options | 6710D |

|---|---|

| Magnetic Head Pulley | Checkmark |

| LED work Lights | Checkmark |

| Dust Control | Checkmark |

| Crossbelt Magnet | Checkmark |

| Scrap Metal collection box | Checkmark |

| Export kit | Checkmark |

| CE Certification | Checkmark |

| Feed Tailgate | Not applicable |

| Cold Weather Kit | Checkmark |

| Air Compressor | Checkmark |

| R+ Package | Checkmark |

| ASG Package | Not applicable |

| Flat Feed Deck | Not applicable |

| Liquid Injection System | Not applicable |

| Tow Dolly | Not applicable |

| Extra-Long Discharge Conveyor | Not applicable |

All specifications subject to change without notice.

Features

Media Gallery

| Current Item | |||||

| Compare Horizontal Grinders |  |  |  |  |  |

| 6710D | 1710D | 2710D | 4710D | 5710D | |

| Standard Engine | CAT C32 Tier IV, 839 kW | CAT C9.3B EU Stage V, 339 kW | CAT C15 Tier IV, 580 hp | CAT C18 Tier IV, 563 kW | CAT C27 Tier IV, 782 kW |

| Scrap Board Production* | 499 m³ | 141 m³ | 247 m³ | 325 m³ | 452 m³ |

| Feed Opening | 168 x 127 cm | 137 x 69 cm | 153 x 81 cm | 152 x 97 cm | 152 x 102 cm |

| Weight | 48,987 kg | 21,092 kg | 28,123 kg | 35,834 kg | 43,091 kg |

*Actual production output may vary due to moisture content, material density and size, support equipment, grate size, and equipment options. Production rates are based on operating 50 minutes per hour with the standard diesel engine.

| Current Item | |||||

| Compare Horizontal Grinders |  |  |  |  |  |

| 6710D | 1710D | 2710D | 4710D | 5710D | |

| Standard Engine | CAT C32 Tier IV, 1125 hp | CAT C9.3B Tier IV, 455 hp | CAT C15 Tier IV, 580 hp | CAT C18 Tier IV, 755 hp | CAT C27 Tier IV, 1050 hp |

| Scrap Board Production* | 653 yd³ | 185 yd³ | 368 yd³ | 425 yd³ | 591 yd³ |

| Feed Opening | 66” x 50” | 54” x 27” | 60” x 32” | 60” x 38” | 60” x 40” |

| Weight | 108,500 lbs | 46,500 lbs | 68,100 lbs | 79,000 lbs | 95,000 lbs |

*Actual production output may vary due to moisture content, material density and size, support equipment, grate size, and equipment options. Production rates are based on operating 50 minutes per hour with the standard diesel engine.