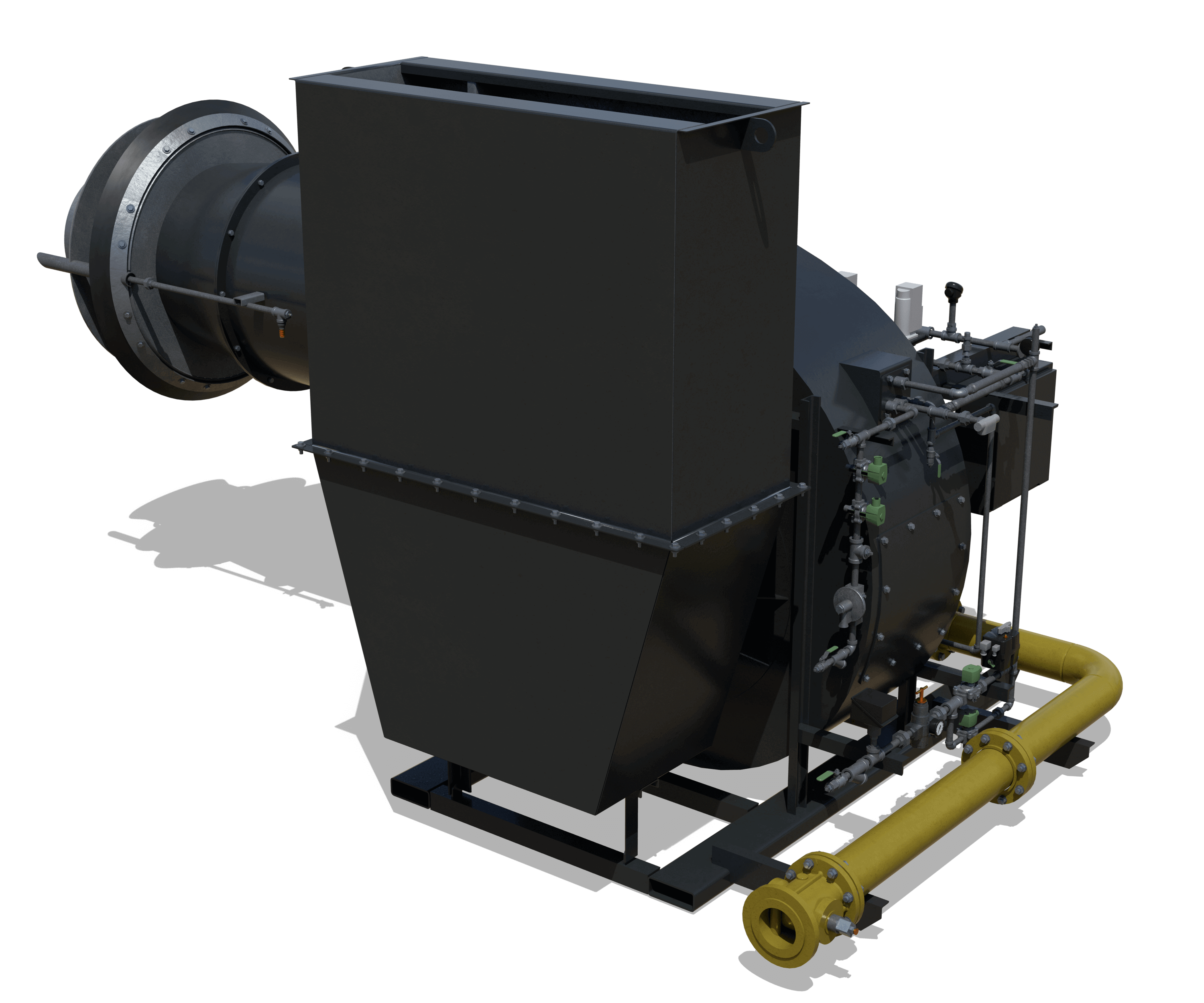

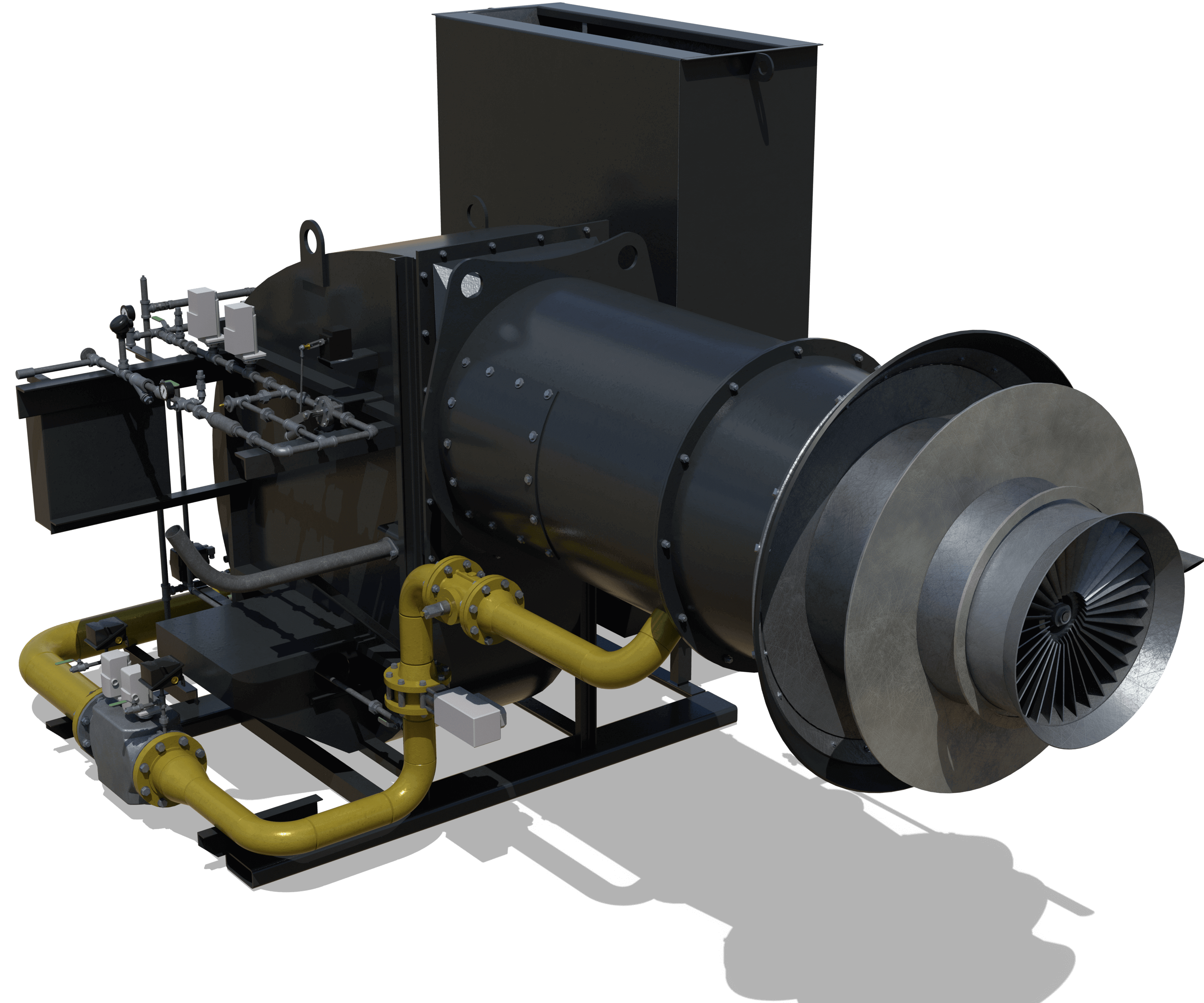

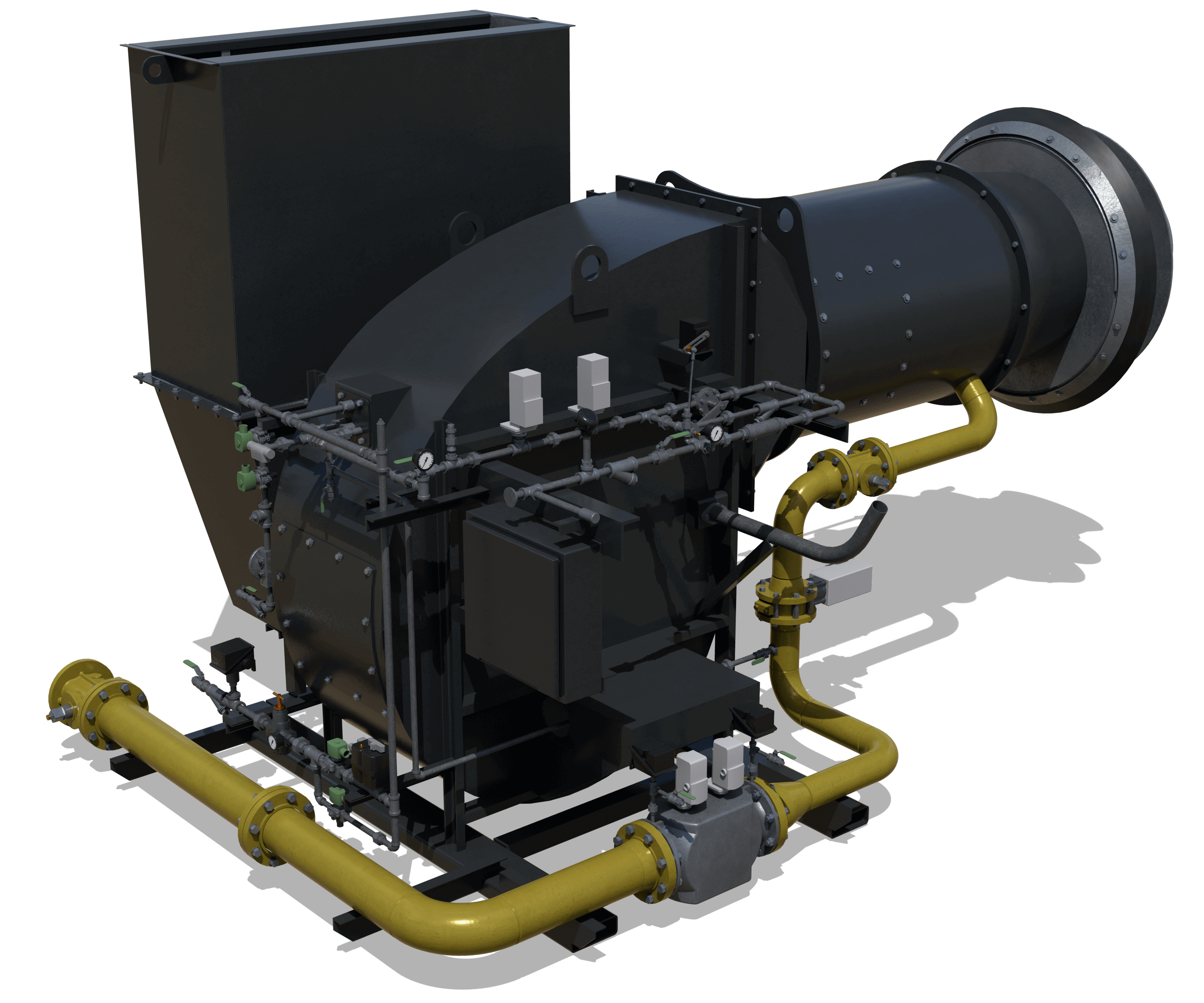

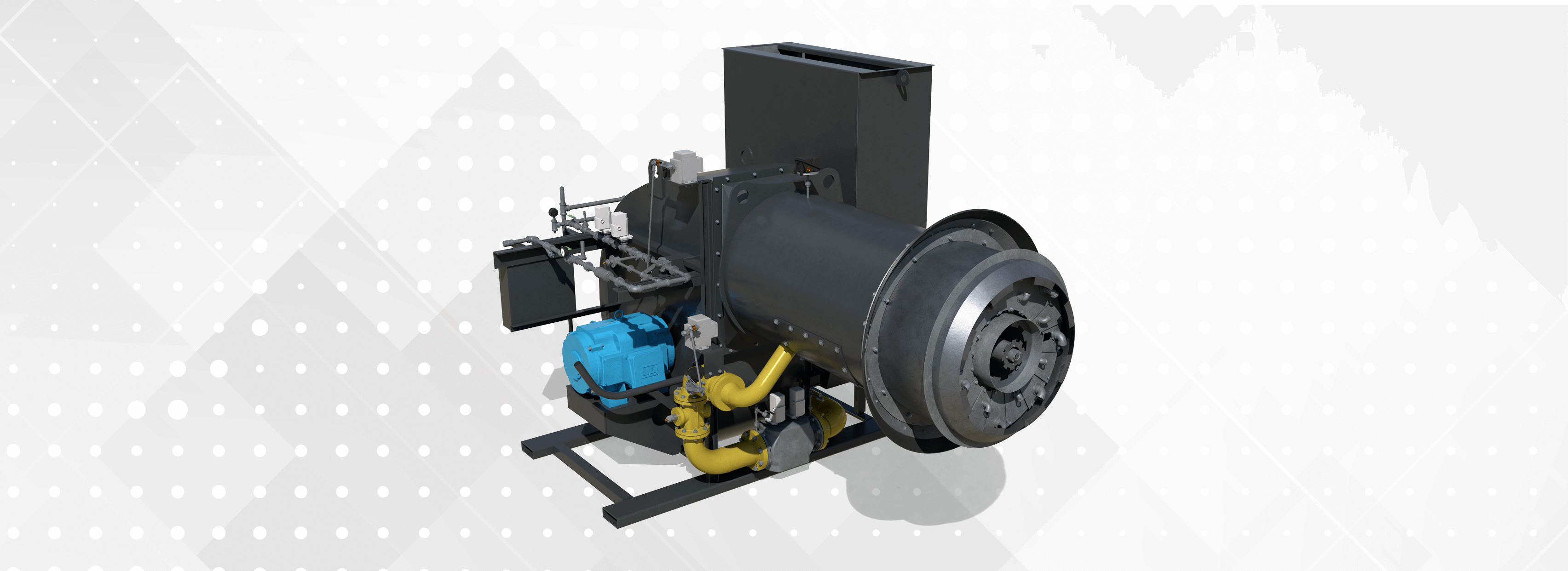

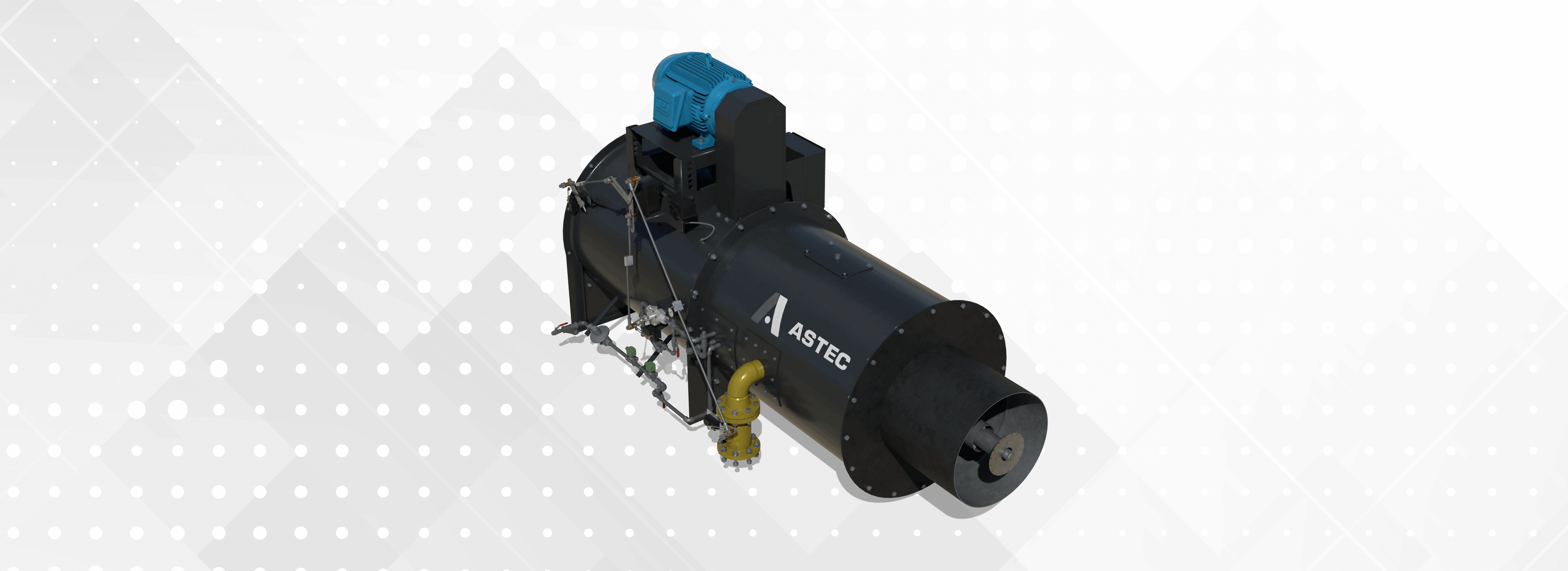

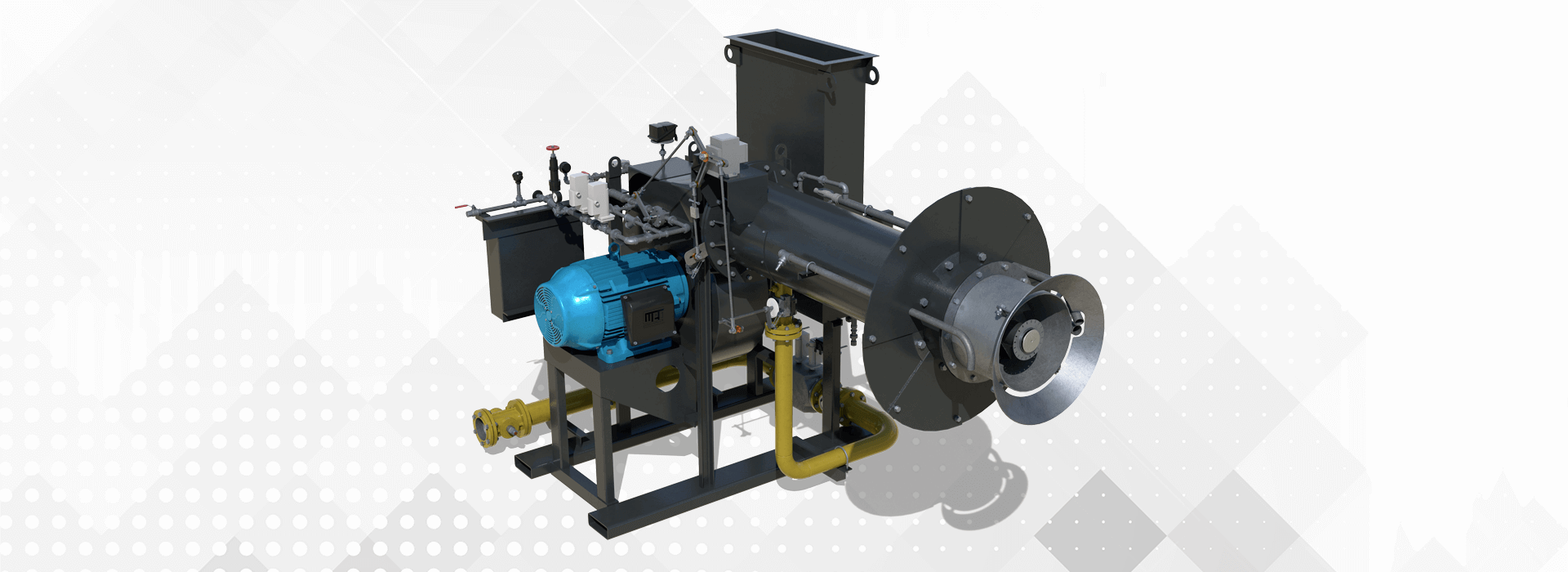

Astec Phoenix® Talon 2 Burner

Overview

Advanced Emission Reduction, Electric Power Efficiency, Firing Efficiency, Compact Flame Size

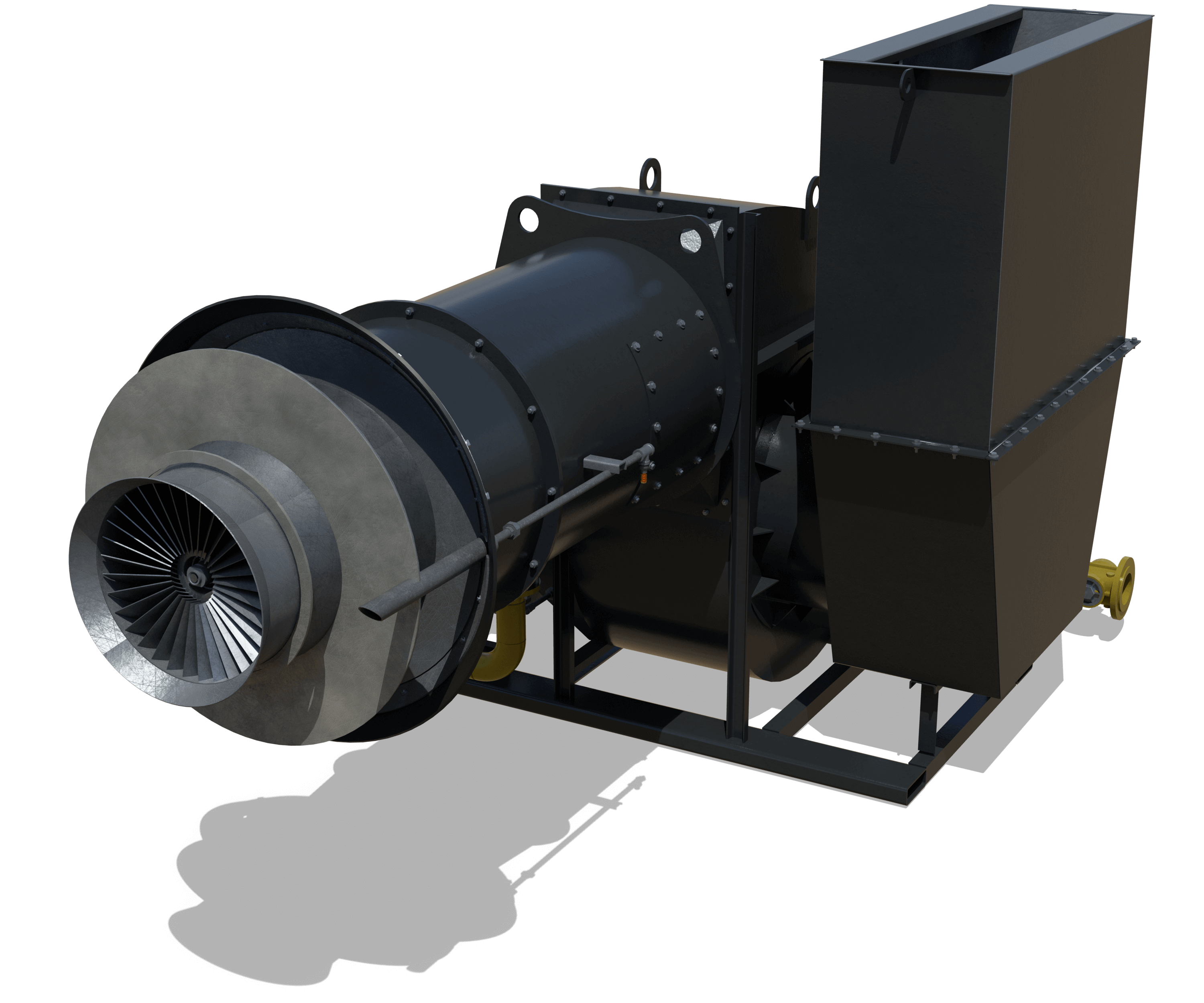

The Astec Phoenix® Talon 2 burner utilizes the latest burner technology to deliver very low emissions combined with energy efficiency. With the optional silencer, it’s even possible to have a phone conversation on the burner platform while it is firing.

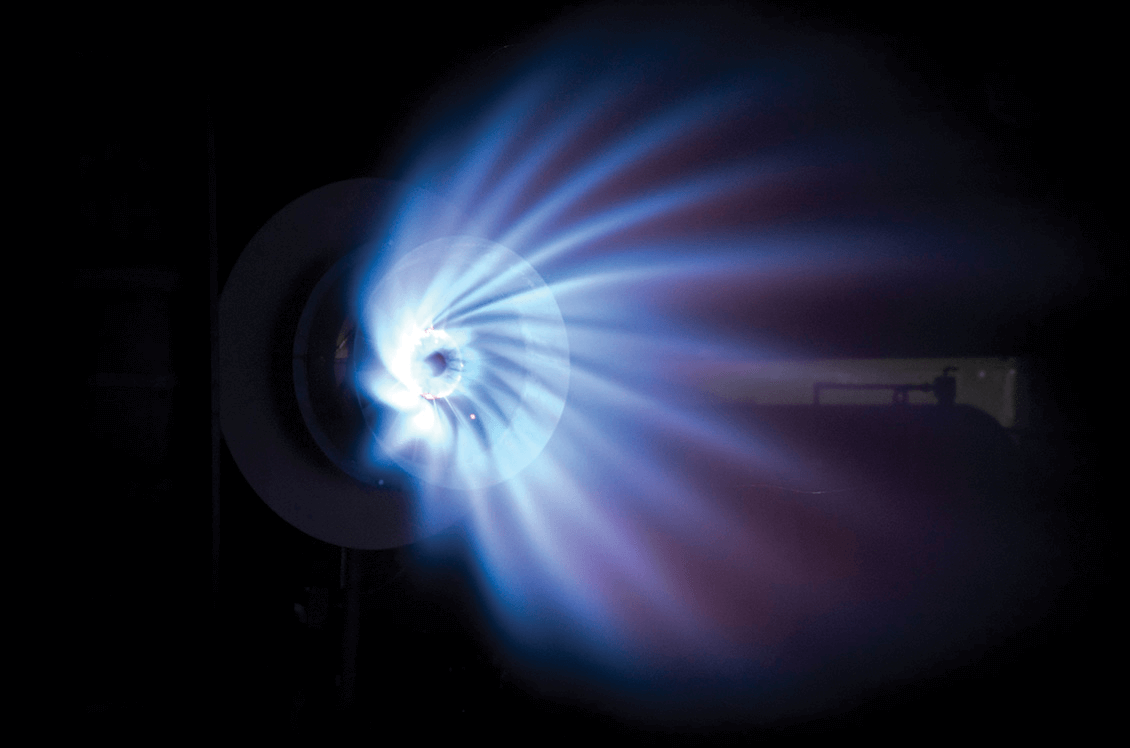

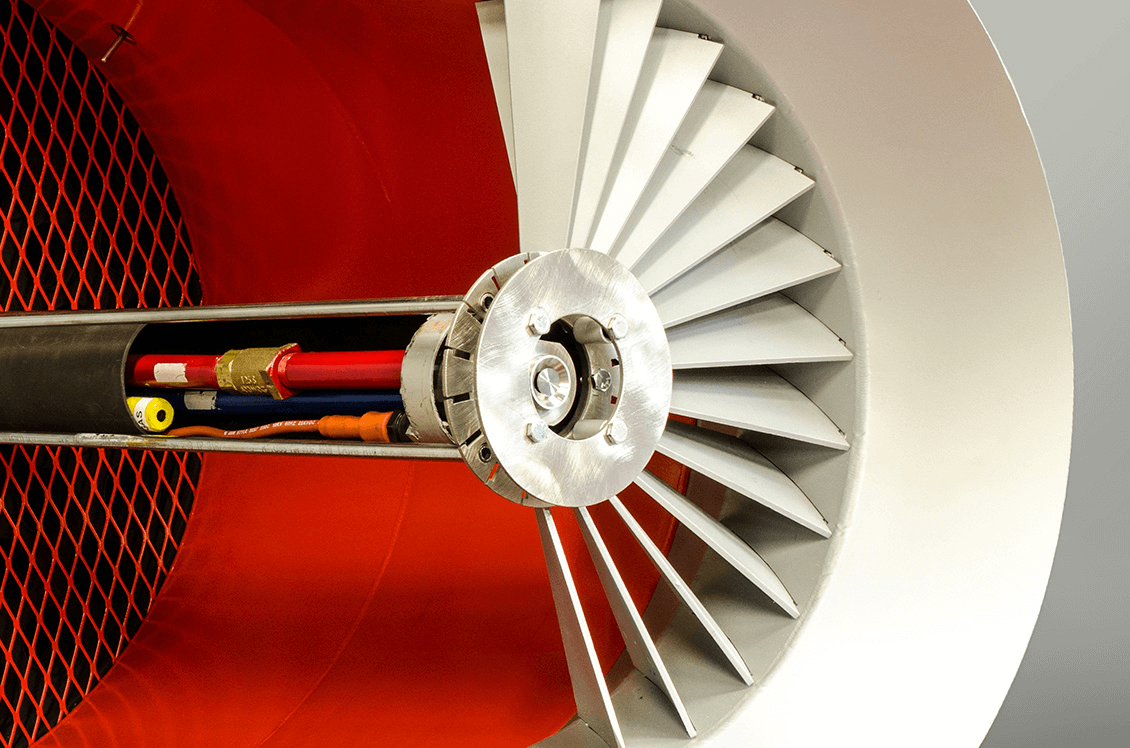

The use of a multiple, parallel, turbulent, tube mixer achieves nearly perfect mixing of gaseous fuel and air to achieve an advanced low NOx and CO method called lean-burn premix. High-quality mixing of air and fuel creates the most compact flame available with a small combustion zone. This ensures that all of the fuel is combusted for peak efficiency without taking away valuable dryer heating capacity.

The variable speed main combustion blower drive helps provide precise firing rate control and uses much less electrical energy. It also eliminates the need for an air damper and for drive motor adjustments and maintenance.

Applications

-

![]()

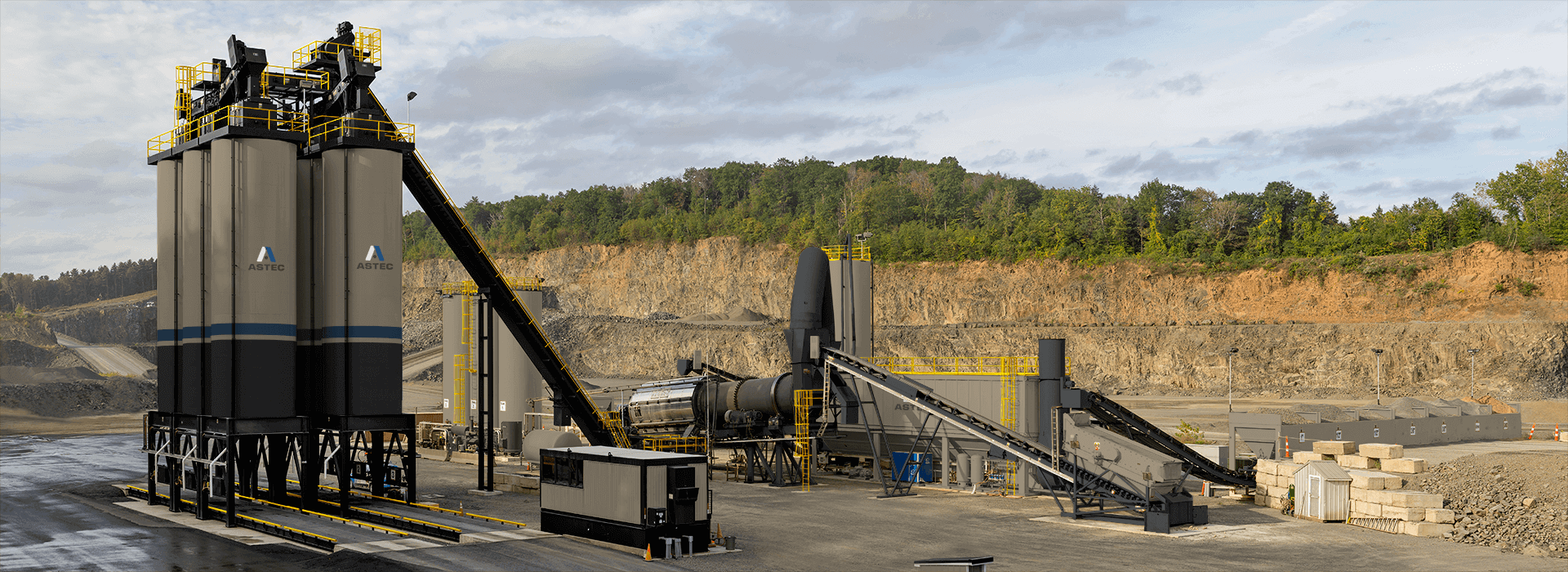

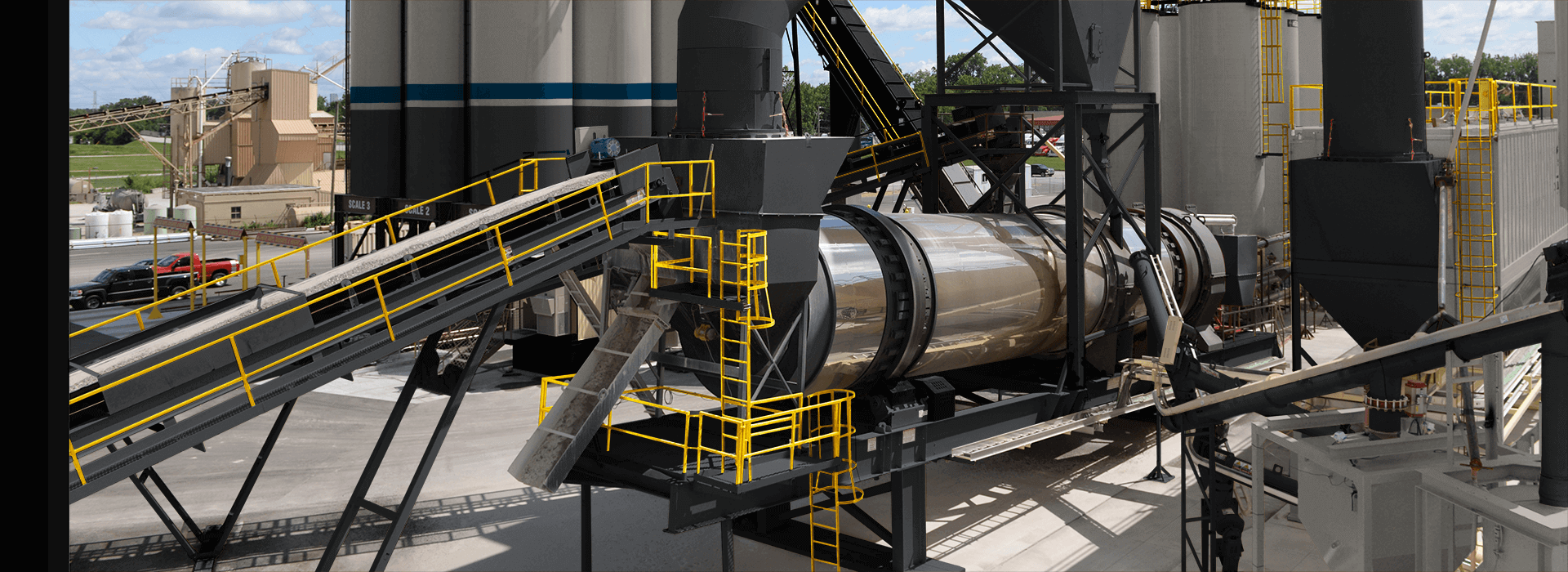

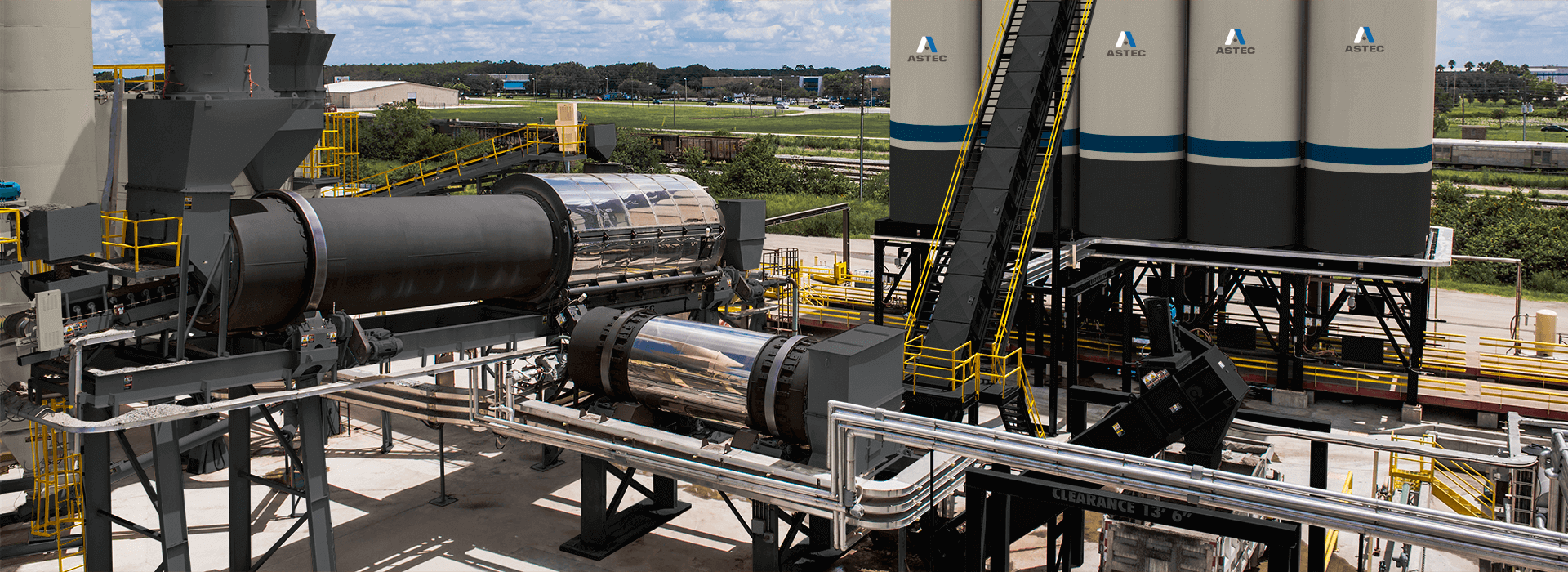

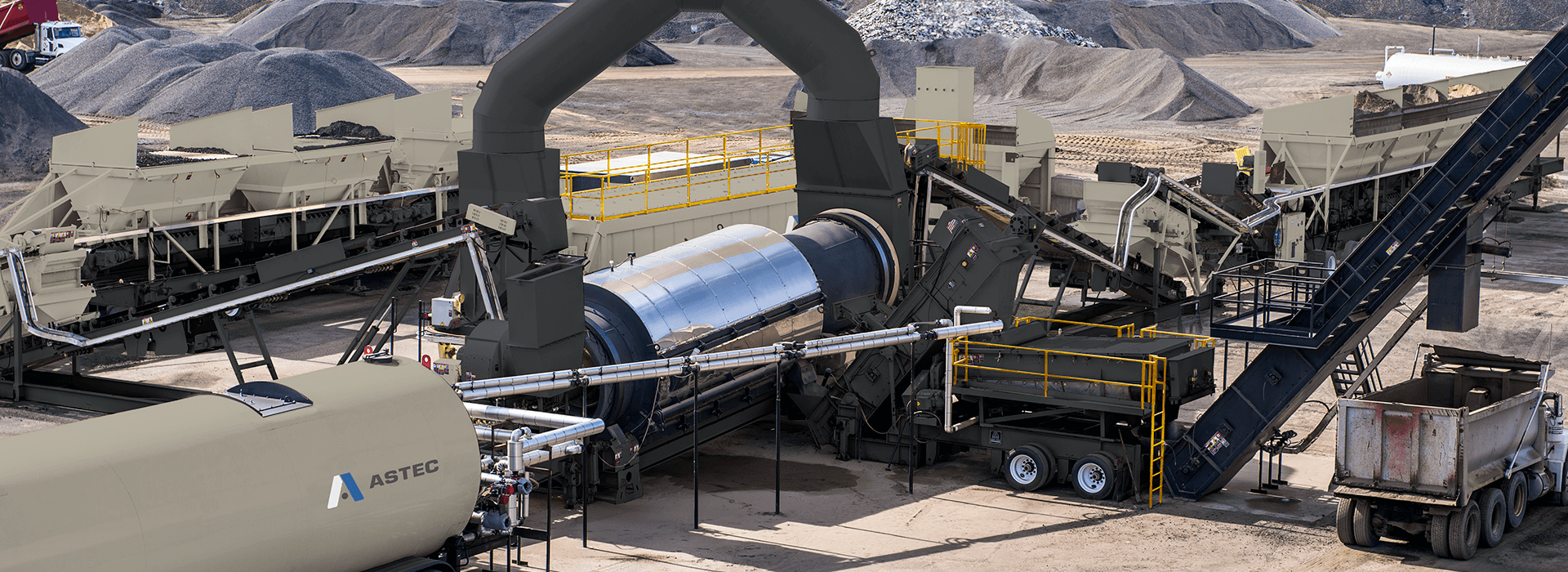

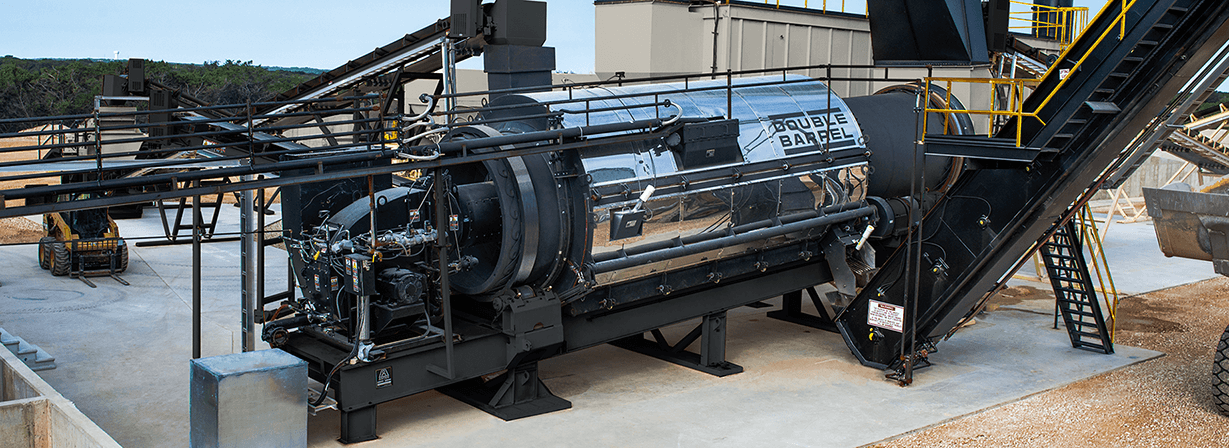

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More

Downloads

Key Specifications

All specifications subject to change without notice.

Above conditions are standard at 75° F at sea level. See detailed capacity, performance sheets for each size for more information and specific flows and pressures. Nominal aggregate drying capacity based on typical exhaust stack temperatures of 240° F, 0.2 BTU/Lbm F specific heat in the aggregate. Burner maximum design capacity is 100% of rated capacity. Advertised numbers are achievable in some conditions, but not guaranteed.