Portable Screening/Washing Plants

Overview

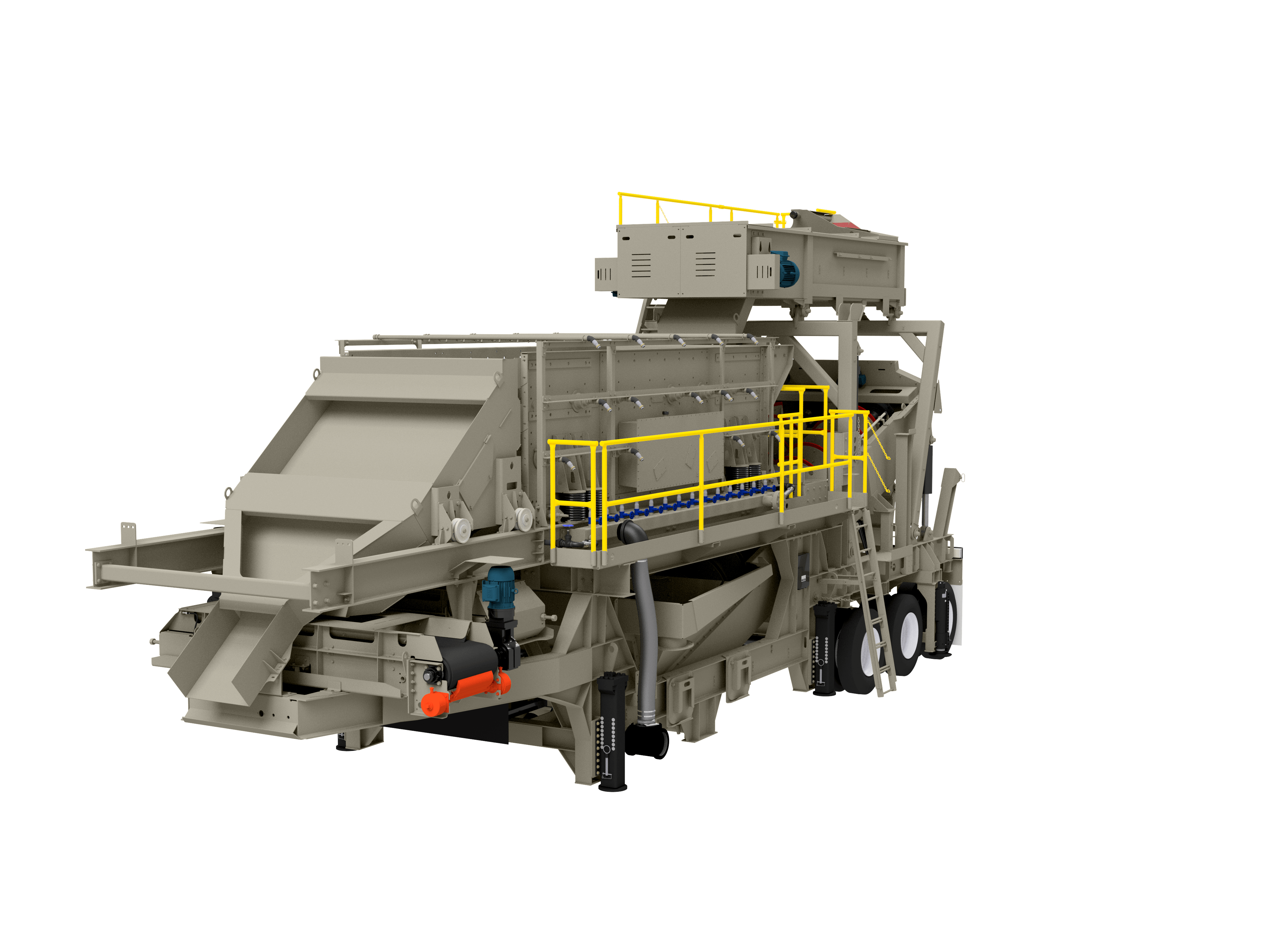

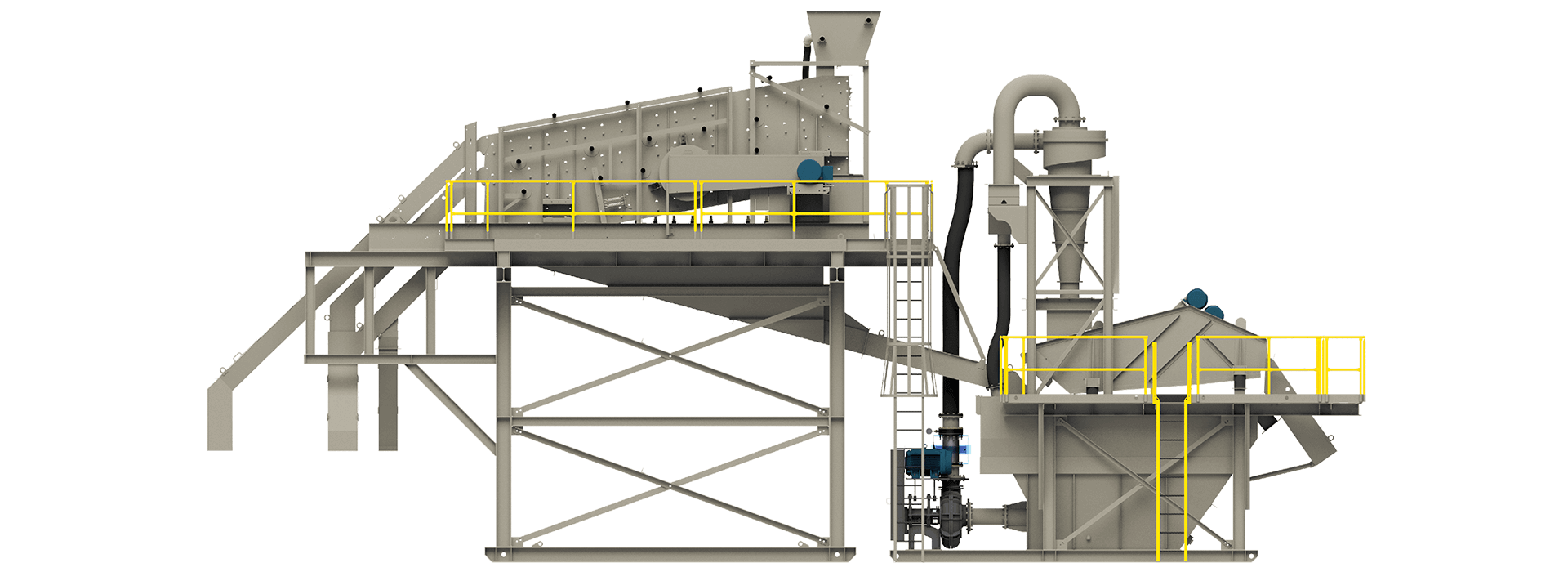

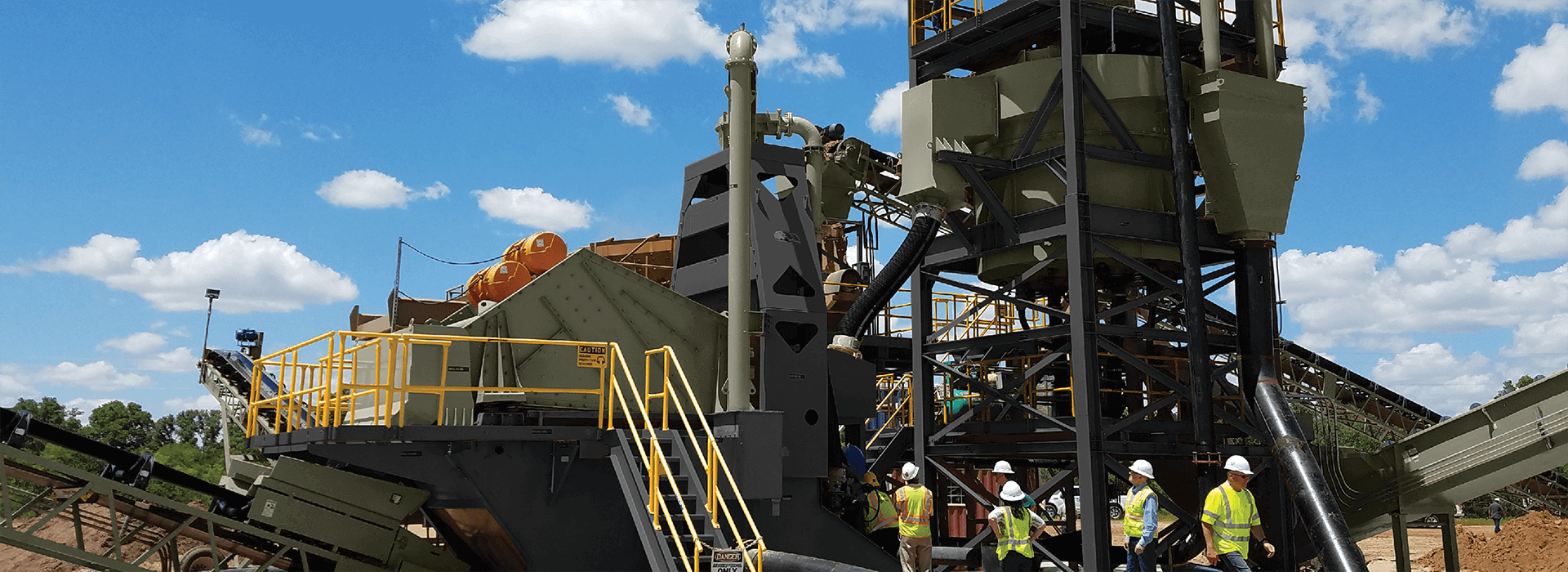

Efficiently process aggregate material wherever opportunities exist with our portable Series 1800 screening and washing plants.

Our Series 1800 plants offer our industry-leading fine material washer with an array of configurations — choose inclined or horizontal wet single-, double- or triple-shaft screens with two or three decks and even add a blademill — all on a single chassis. Standard and custom-built skid-mounted or stationary plants are available with an unlimited number of configurations and options to meet any application.

Applications

-

![]()

Aggregates

There are two main classes of aggregates: natural and manufactured. Deleterious material needs to be removed from both classes. Processing these materials typically requires various steps including reduction and sizing and also may include dewatering and sorting. Producers can use a variety of crushing, screening, dewatering and conveying equipment to meet their desired specifications.Learn More -

![]()

Construction Aggregates

Construction aggregate is typically medium or coarse materials like granite, limestone or trap rock, sand, gravel, slag or recycled concrete. Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles.Learn More -

![]()

Sand & Gravel

Aggregates, when gathered, may contain clays, silts and other deleterious material that needs to be processed out for commercial-grade products.Learn More

Downloads

Key Specifications

All specifications subject to change without notice.

/ranger-plants/ranger-line-header-02.jpg?sfvrsn=c145462e_5)