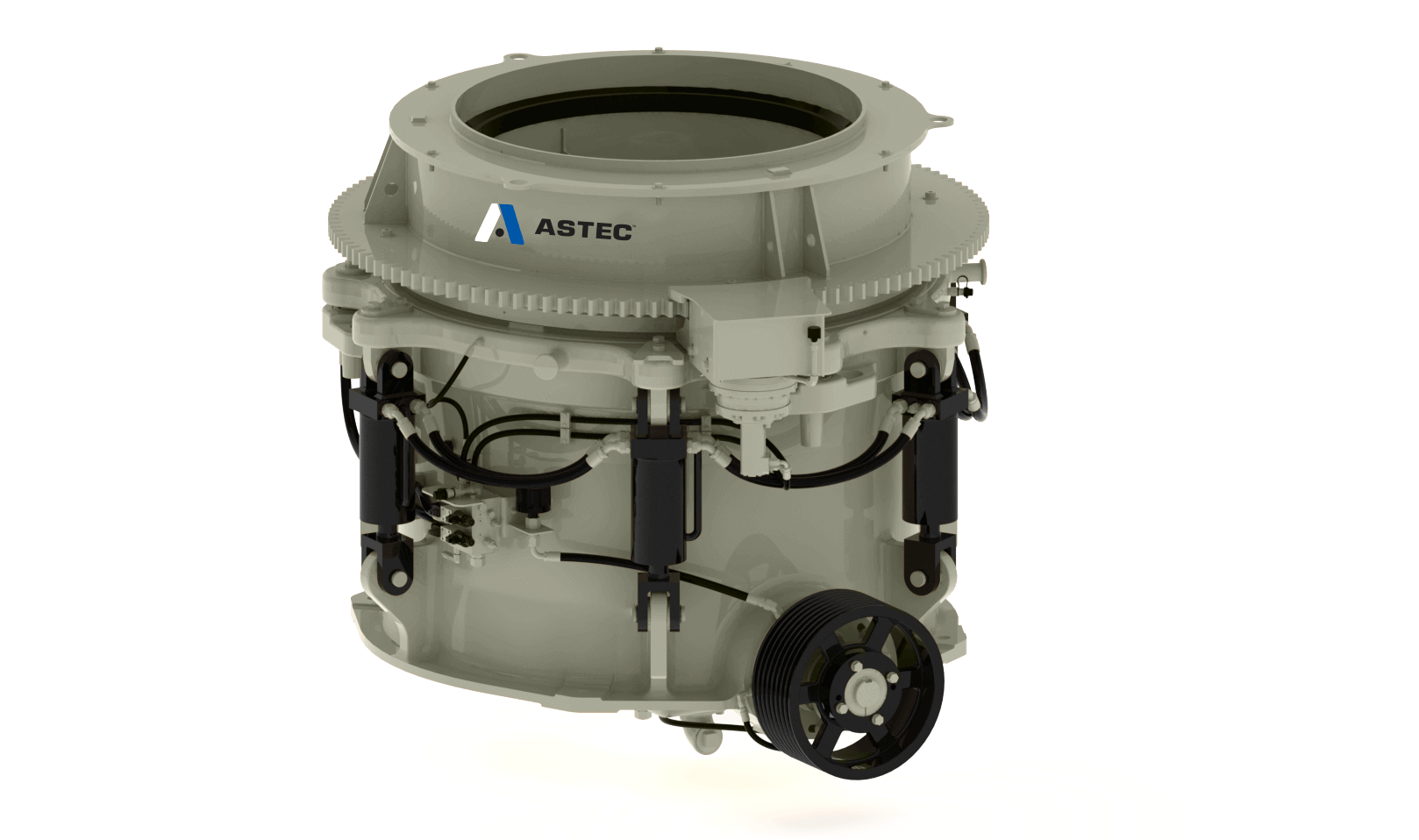

Titan® Cone Crushers

Overview

Titan® cone crushers are engineered to deliver uncompromising productivity, safety and ease-of-maintenance for maximum uptime in tough, abrasive applications.

With four sizes ranging from 200 to 500 horsepower, and capacities from 100 to 760 metric tons per hour, there is a Titan® cone for every application.

Applications

-

![]()

Sand & Gravel

Aggregates, when gathered, may contain clays, silts and other deleterious material that needs to be processed out for commercial-grade products.Learn More -

![]()

Crushed Stone

Crushed stone is a versatile product that can be used in a wide range of applications from construction to road building and even agriculture. Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles.Learn More -

![]()

Construction Aggregates

Construction aggregate is typically medium or coarse materials like granite, limestone or trap rock, sand, gravel, slag or recycled concrete. Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles.Learn More -

![]()

Aggregates

There are two main classes of aggregates: natural and manufactured. Deleterious material needs to be removed from both classes. Processing these materials typically requires various steps including reduction and sizing and also may include dewatering and sorting. Producers can use a variety of crushing, screening, dewatering and conveying equipment to meet their desired specifications.Learn More -

![]()

Construction & Demolition Recycling

Construction and demolition recycling (C&D) is mixed material associated with construction and demolition. The material could include wood, cardboard, gypsum, plastic, metal, wire, roofing shingles, asphalt, concrete and more. By separating and recycling different materials it reduces landfill waste and associated costs, while also producing value-added products.Learn More -

![]()

Concrete Recycling

Concrete is one of the most recycled materials in the world and can be repurposed several times over. Once the existing concrete is demolished or torn up, it needs to be processed for accurate shaping and sizing using a crusher and screen.Learn More

Downloads

Key Specifications

All specifications subject to change without notice.

/ranger-plants/ranger-line-header-02.jpg?sfvrsn=c145462e_5)

/mobile-hsi-ft4250-concrete-application-header-01.jpg?sfvrsn=e7637d85_5)