Astec ReMix™ Cold Central Plant Recycle System

Overview

CCPR is a cold recycling technology. It is a sustainable approach to road construction that minimizes the environmental impact. By reusing RAP materials and mixing them at ambient temperatures, the CCPR significantly reduces the need for both virgin aggregate and energy for heating the mix. This conserves natural resources and lowers carbon emissions.

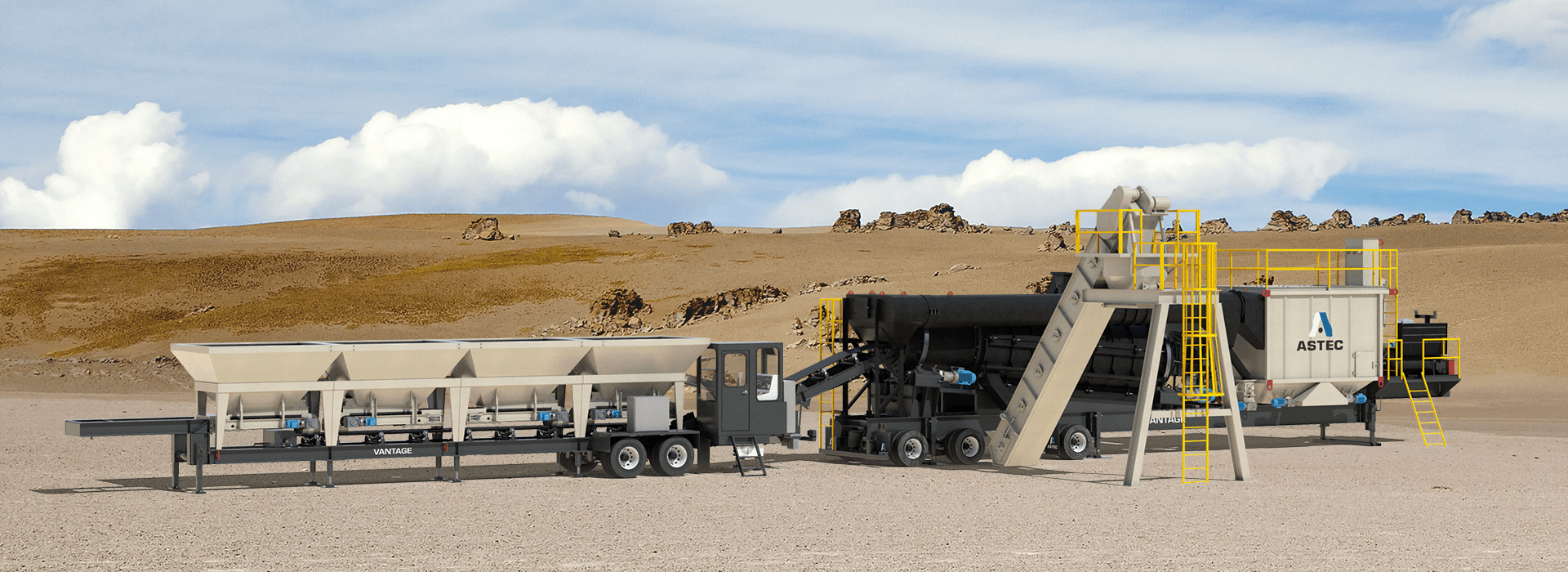

The Astec ReMix™ system is a modular solution, comprised of the following components:

A core load with a trailer chassis, 300 TPH (nominal) pugmill, feed conveyor, controls system, water line connection, shore power connection, water pump & metering system, and either a foamed asphalt injection system or an asphalt emulsion injection system.

Options:

- Five options for RAP feed, including integrated bins or standalone RAP bins

- Four options for material discharge

- Eight options for fines additive supply

- Three options for liquid asphalt supply

- Additional options available to include a flushing system to clean out the AC lines and spray bar, an integrated asphalt pump & metering system, and more.

Case Study

How Environmentally Responsible Roadbuilding

Benefits Your Bottom Line

Industry Resources

NCHRP Construction Guidelines for CCPR and CIR

NCAT CCPR Test Track Findings

NCAT Offers CCPR Mix Design

Applications

-

![]()

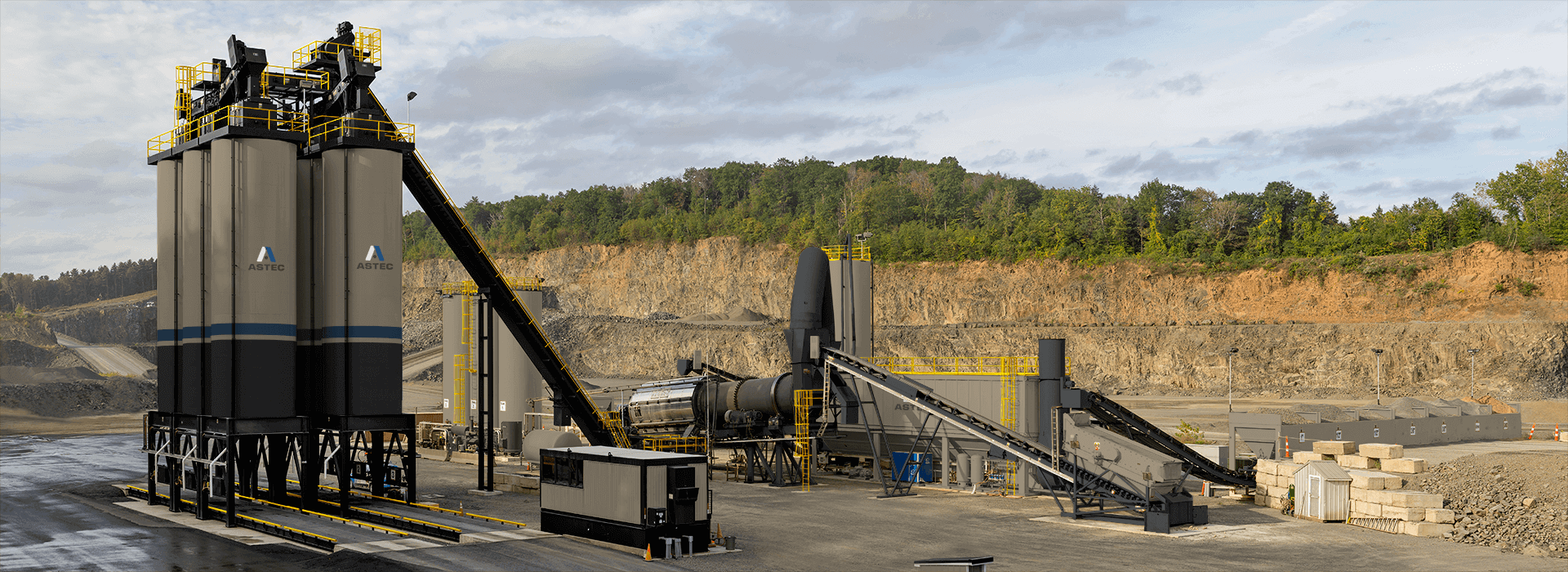

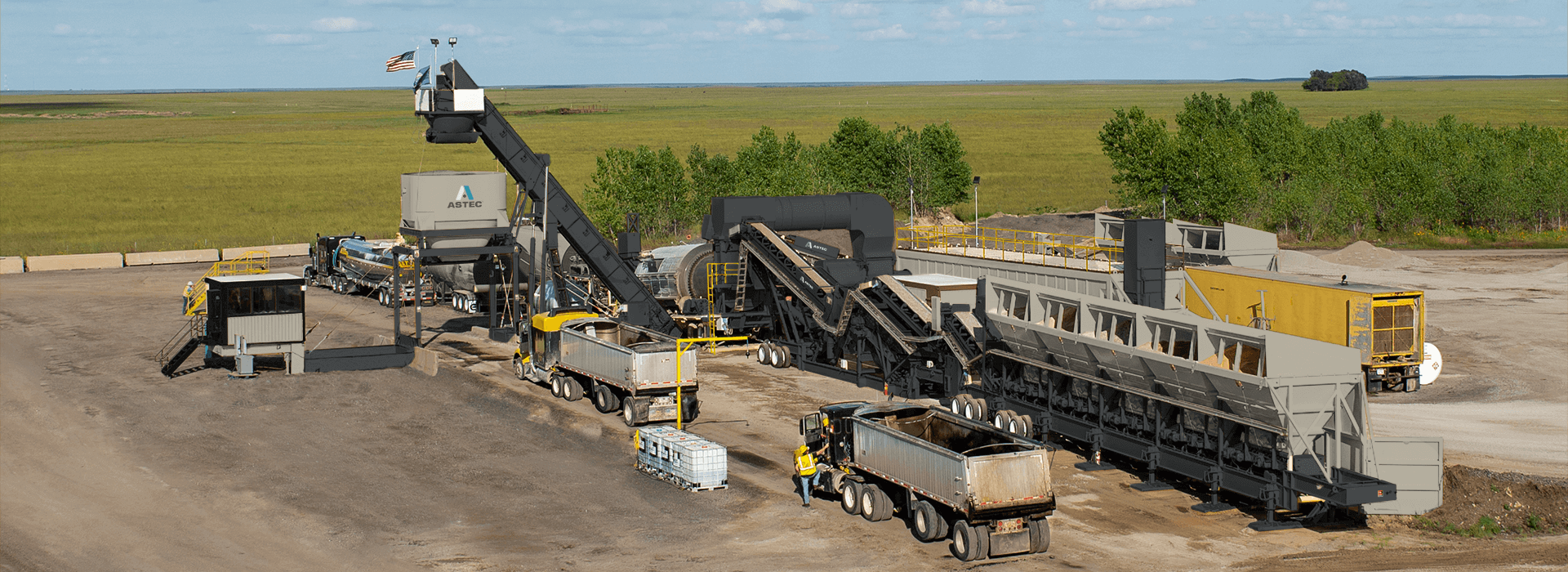

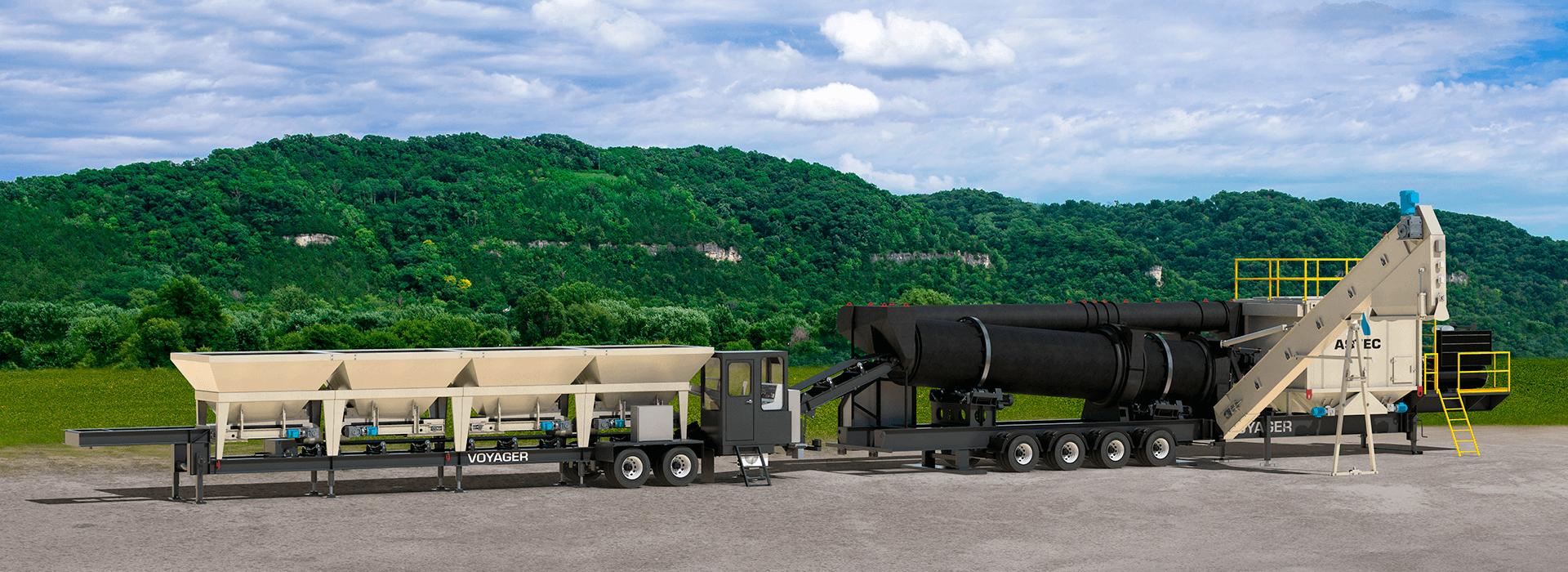

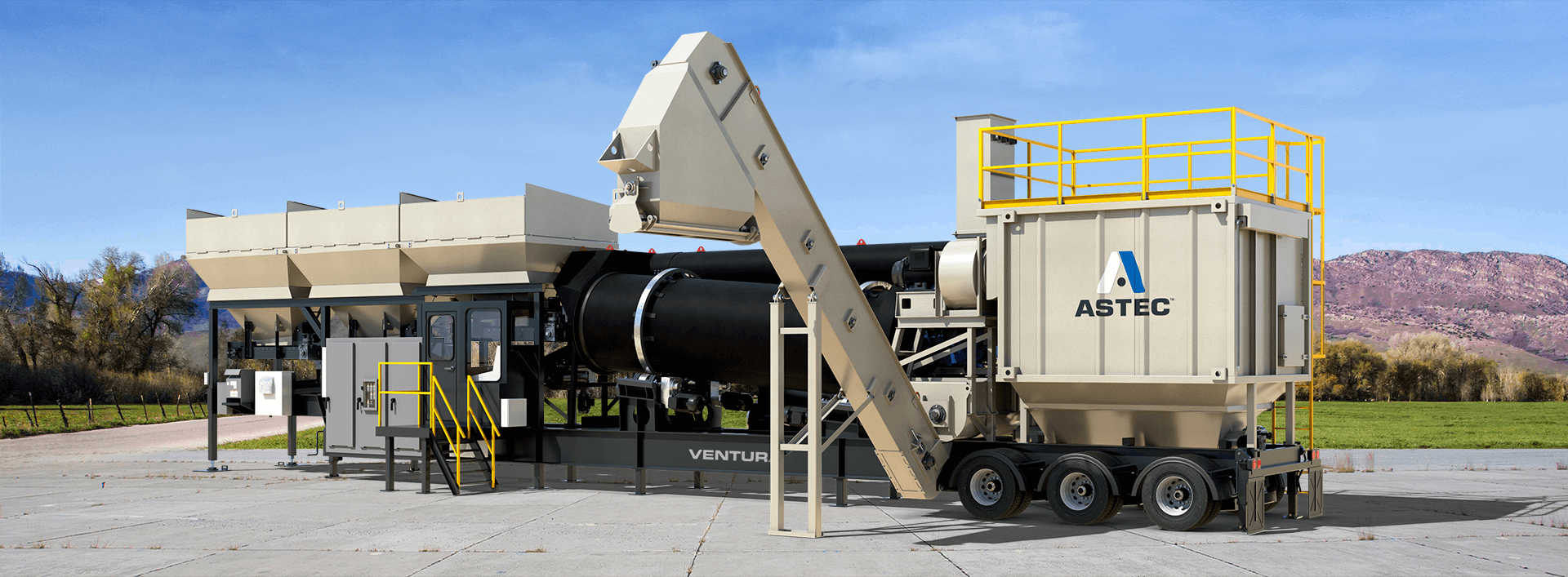

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More -

![]()

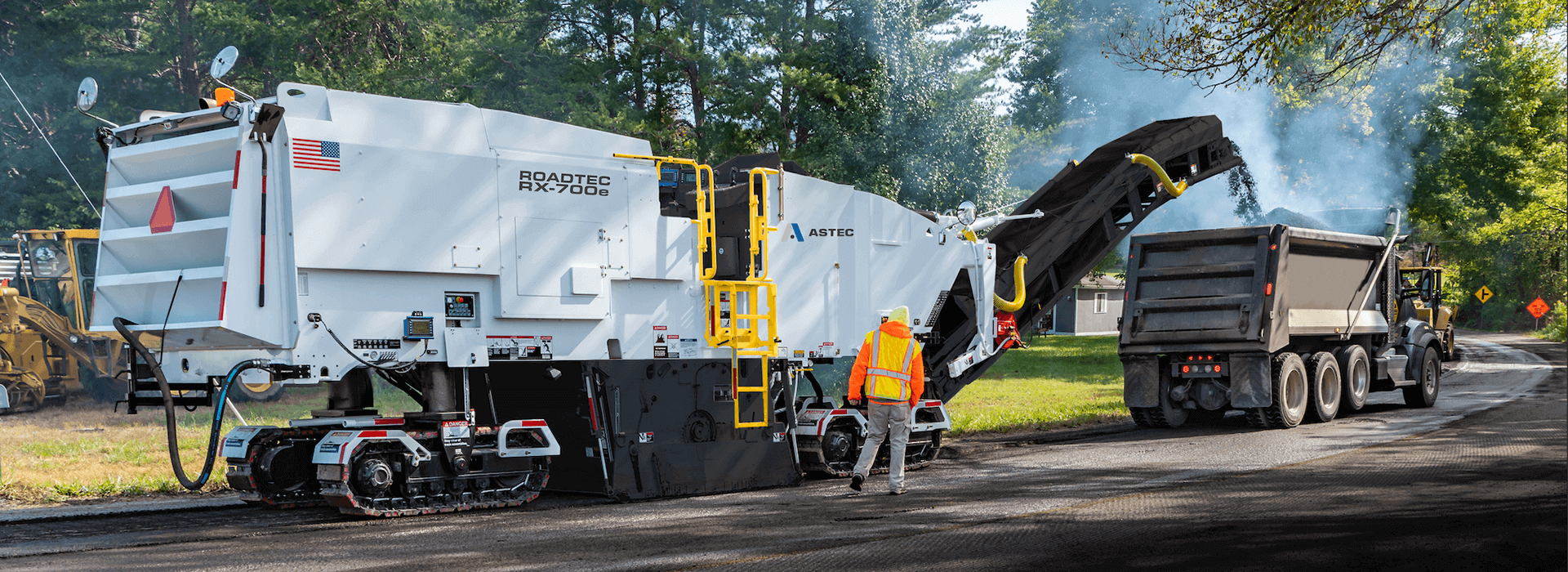

Recycled Asphalt Pavement

Recycled asphalt pavement (RAP) is asphalt paving material recovered from old road beds either by milling or excavation.Learn More