Peterson 1710D Horizontal Grinder

Delivering high-impact performance in a surprisingly compact package, the 1710D Horizontal Grinder combines a nimble transport footprint with a powerful Cat® C9.3B engine and a robust feed system—making it ideal for recycling operations that demand consistent efficiency and versatile performance.

Feed Opening:

54" x 27" (137 x 69 cm)

Horsepower:

455 hp (339 kW)

Machine Weight:

46,500 lbs (21092 kg)

Overview

Heavy duty and mobile, the 1710D Horizontal Grinder can readily reduce a wide range of materials.

The 1710D’s large feed opening, measures 54″ x 27″ (137 x 69 cm). When boosted by Peterson’s high-lift feed roll, the feed opening’s maximum lift of 41.5 inches (105 cm) can tackle the largest of feedstock, and allows excellent accessibility to the rotor for maintenance.

The 1710D Horizontal Grinder is equipped with a Caterpillar Tier IV C9.3B 455 hp (Stage V, 339 kW) engine, or an optional, export-only C9.3B Tier III, 415 hp (309 kW) engine. At 46,500 pounds (21,092 kg), it is one of the lightest of Peterson’s grinder series, and is easily transportable.

The 1710D Horizontal Grinder features a quick-change multiple grate system, making it easy to customize grate configurations. Grates are removed through an easy-access door on the side wall. With Peterson’s patented up-turn rotor, and heavy-duty bits, and robust anvil, the 1710D has an exceptional wear life and accurate product sizing.

Features

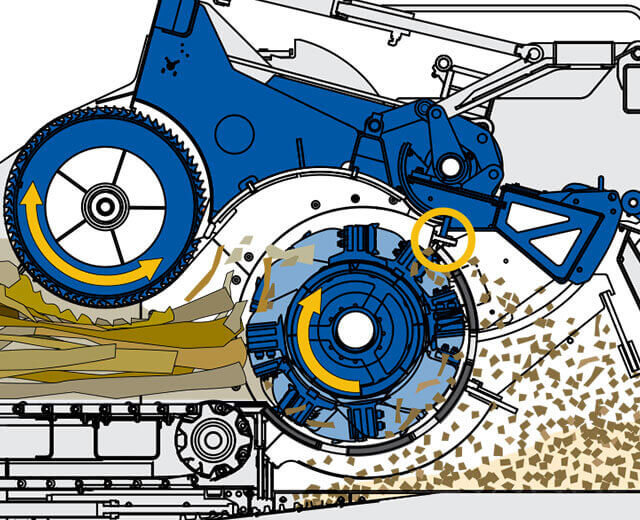

3-Stage Grinding Process

The powerful up-turn 3-stage grinding process provides better fracturing of material and a more consistent product, giving you just the product your buyers want.

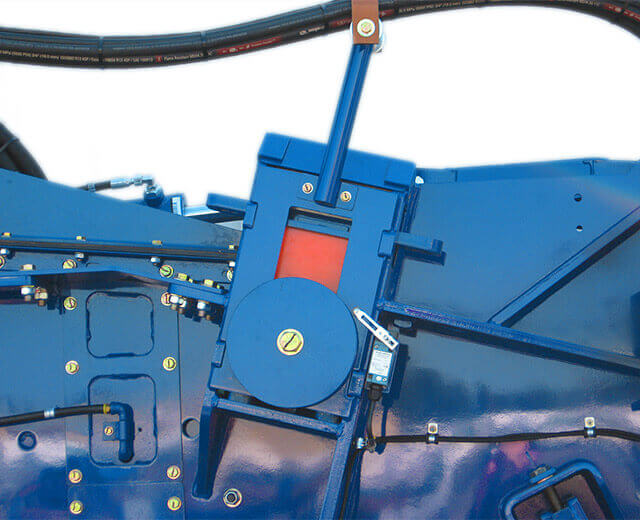

Impact Release System Protects Your Investment

The air bags on the patented Astec Impact Release System provide uniform grinding and protection from contaminated feedstock, a feature unique to Peterson grinders.

The Second Line of Defense: the Impact Cushion System

Urethane cushions and shear pins help protect the mill from catastrophic damage in the event of a severe impact from contaminants in the feedstock.

Downloads

Specifications

All specifications subject to change without notice.

Where to Buy

Find an Astec Dealer Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Biomass

Biomass is an energy source derived from renewable and sustainable organic materials to create electricity or other forms of power.

Learn More about Biomass

Land Clearing

Land clearing generally consists of trees, limbs & roots cleared from forested or partially forested land that will be used for a new purpose including farming, commercial development or right-of-ways

Learn More about Land Clearing

Mulch

Organic mulch is a product that can decompose, providing nutrients to the soil over time.

Learn More about Mulch

Organic Recycling

Green waste recycling turns biodegradable materials into compost, keeping them out of landfills and enriching gardens.

Learn More about Organic Recycling

Wood Waste Recycling

Wood waste is the second largest category of construction and demolition (C&D) debris, and accounts for 10% of material added to landfills annually.

Learn More about Wood Waste Recycling