Heatec Reboiler

Heatec Reboilers are fired heat exchangers that can be used in systems that process natural gas for pipeline distribution.Two of these units may be used in a gas processing system. One may be used to regenerate glycol and the other to regenerate amine.

Overview

Heatec Reboilers are fired heat exchangers that can be used in systems that process natural gas for pipeline distribution.

Two of these units may be used in a gas processing system. One may be used to regenerate glycol. The other may be used to regenerate amine. When glycol is used to remove moisture from gas the glycol becomes a mixture of glycol and water. It must be regenerated before it can be reused. Regeneration removes the water from the glycol. The reboiler provides heat for this process. Heating the glycol-water mixture vaporizes the water, while the glycol remains mostly liquid. The vapors are usually piped to a distillation column, which recovers glycol that may have vaporized.

When amine is used to remove hydrogen sulfide (H2S) and carbon dioxide (CO2) from gas, it too must be regenerated before it can be reused. Regeneration removes these contaminants from the amine. The re-boiler provides heat for this process.

Features

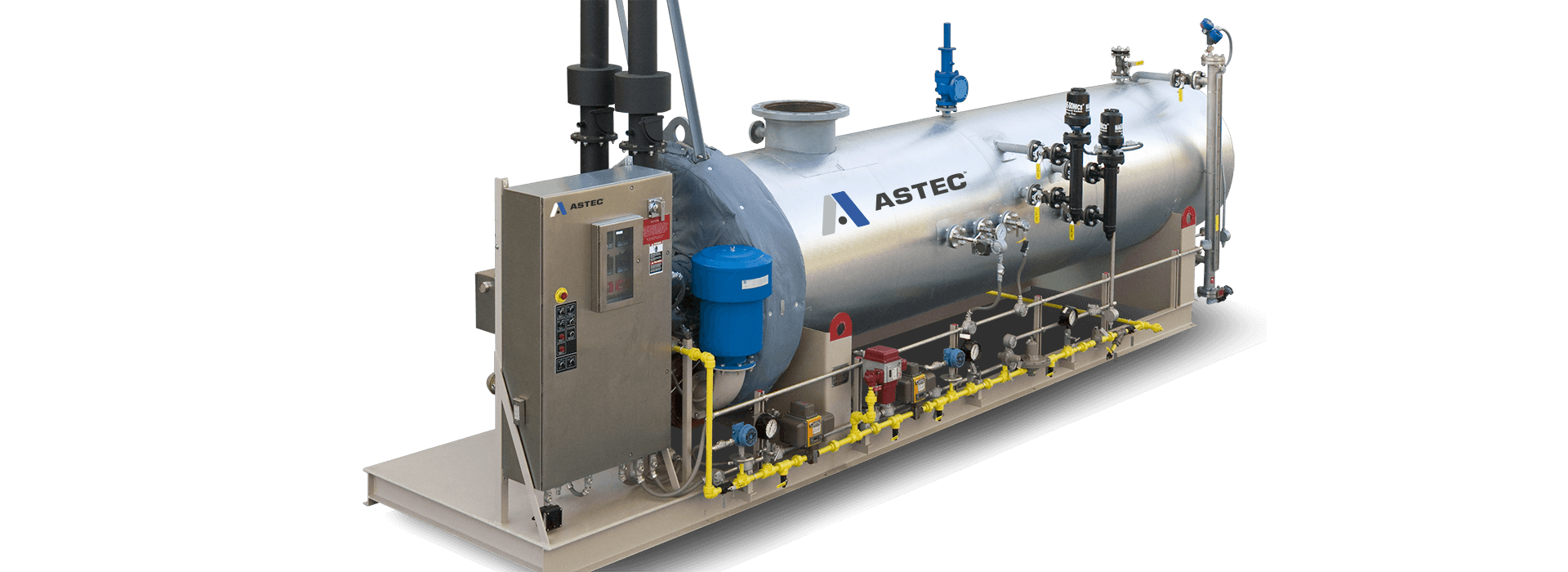

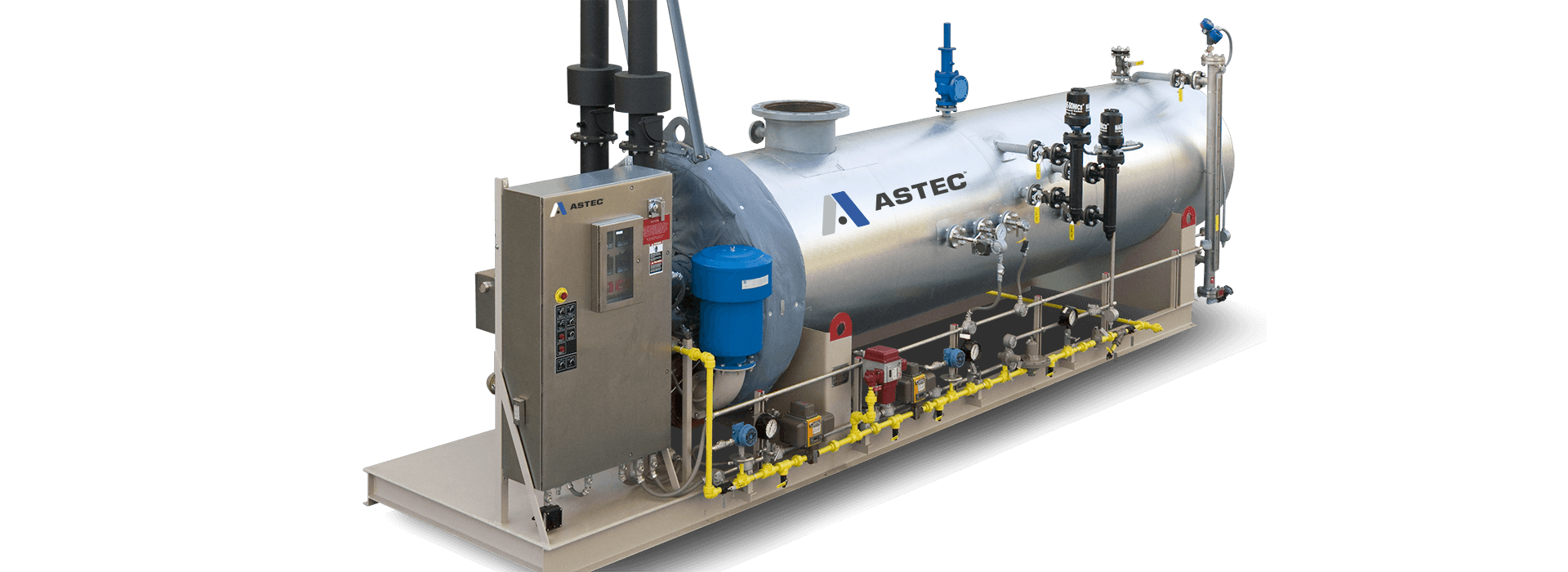

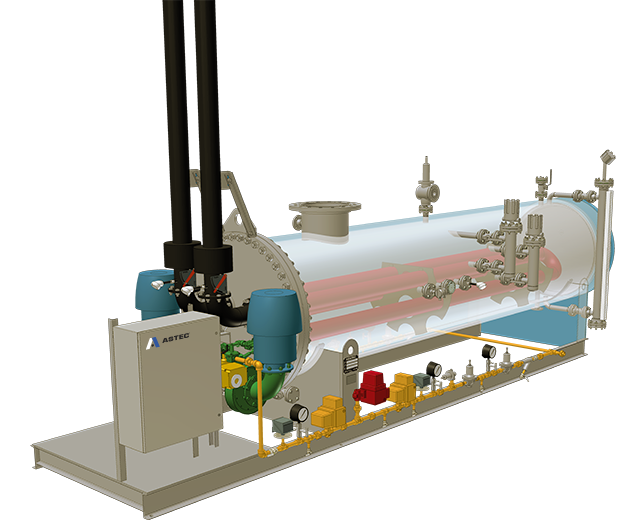

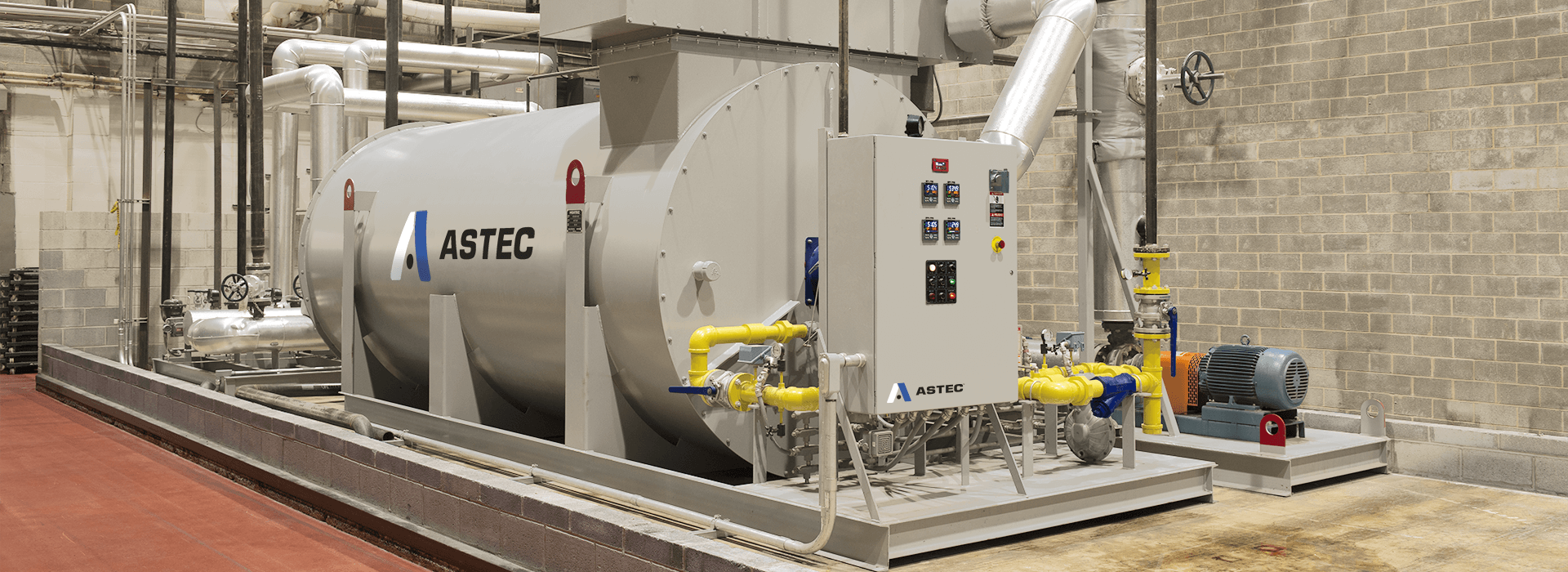

Heatec Fire Tube Reboiler

Our reboilers can be configured for a specific use and to suit customer needs. In its standard configuration the unit consists of a steel shell that contains two long-life fire tubes, each with a separate burner. The fire tubes are removable and can be replaced if necessary.

The forced draft burners are gas-fired. Natural draft burners are optional. Each burner has a turndown ratio of 10 to 1. Use of two burners provides a combined turndown ratio of 20 to 1.

The reboiler has natural circulation within the unit and does not require a booster pump. This reduces the electrical energy required—an important consideration for offshore platforms.

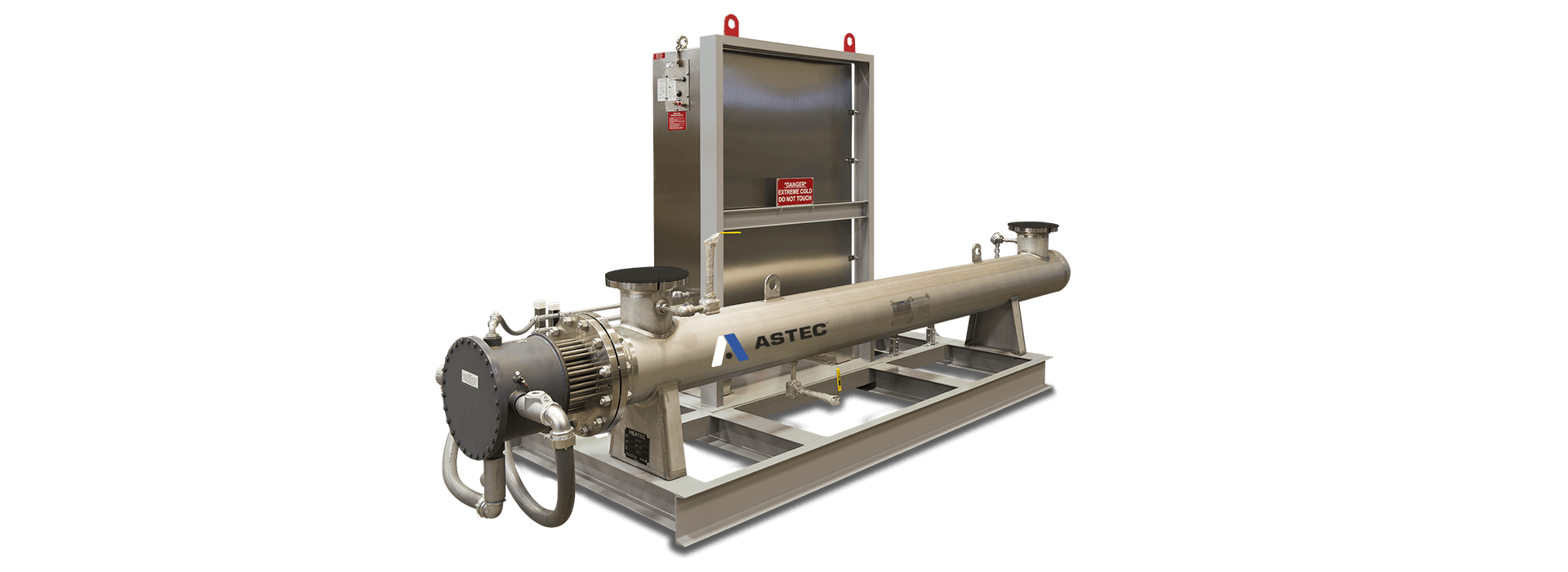

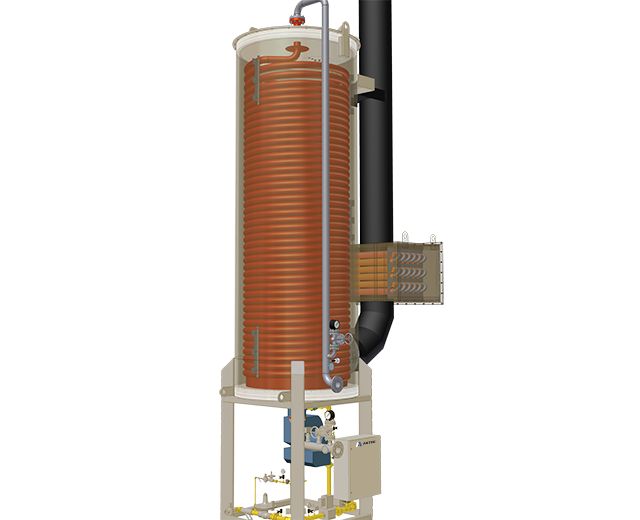

Heatec Helical Coil Reboiler

The unit has one or more helical coils that resemble those in HMO heaters or conventional thermal fluid heaters, also used in gas processing. However, these units should not be confused with each other. Unlike HMO heaters, the glycol or amine is heated directly as it flows through the coils of the reboiler.

The reboiler can be designed with one or more coils, depending on the flow rate needed. The shell of the unit is insulated to minimize heat loss and increase thermal efficiency. The vertical orientation of the reboiler uses a smaller footprint than the fire tube reboiler. It also makes draining the coils easier. Our reboilers can be provided in various sizes to meet customer needs.

Downloads

Where to Buy

Find an Astec Dealer Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Chemical

Chemical plants convert oil, natural gas, air, water, metals, and minerals into chemical products.

Learn More about Chemical

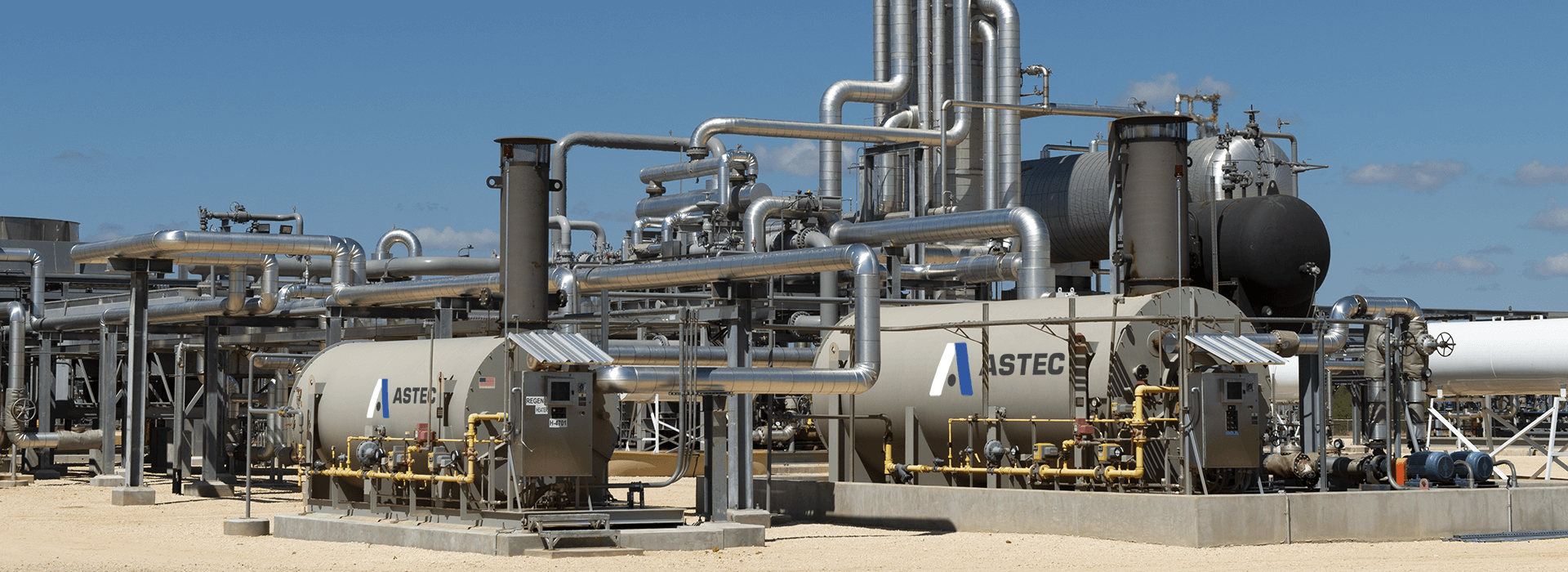

Crude Oil & Natural Gas Processing

Refining and processing crude oil and natural gas require highly reliable and efficient heating systems and services.

Learn More about Crude Oil & Natural Gas Processing

Paints, Resins & Adhesives

Astec has a long history producing trustworthy and efficient thermal systems that can be used in the production of paints, resins, and adhesives.

Learn More about Paints, Resins & Adhesives