Peterson R+ Grinder Package

With 10+ years of development, the R+ package combines the very best in engineering and innovative design to equip a typical “high speed” Peterson horizontal grinder into a “medium speed” machine.

Overview

With 10+ years of development, the R+ package combines the very best in engineering and innovative design to equip a typical “high speed” Peterson horizontal grinder into a “medium speed” machine, utilizing the production of a typical high speed grinder, and the protection of a slow-speed shredder.

With performance nearly doubling the output of typical slow speed shredders, R+ equipped Peterson horizontal grinders offer a solution that has high output, and superior machine protection against ungrindable materials.

Typical R+ applications include Municipal Solid Waste (MSW), Construction and Demolition (C&D) debris, chunk wood such as stumps, storm debris, railroad ties, and other materials.

The R+ package uses a specially designed rotor with high and low bits, that turns at half the speed of our standard units. This processes material through a specialized heavy duty grate, with the high and low bits passing through the fingers, providing extensive fracturing surfaces for superior product reduction.

The R+ package utilizes Peterson’s patented Impact Release System, and Impact Cushion System to protect your investment against an ungrindable object, but has additional modifications such as a heavier duty cushion block to prevent nuisance openings, and an upgraded Impact Release System designed to perform in the harsher environment.

Other mods include more space for ground material to exit the machine, and a heavier duty discharge belt.

Already own a Peterson grinder? Your 4700, 5700, or 6700-series machine may be able to be upgraded as a package so you can take on the difficult jobs that you may have passed by before. Likewise, if you no longer need the protection of the R+ package, and your grinder is going into other applications, the R+ specific parts can be removed and replaced with standard units to change the machine back to a standard “high speed” grinder– no other machine on the market can do that!

Features

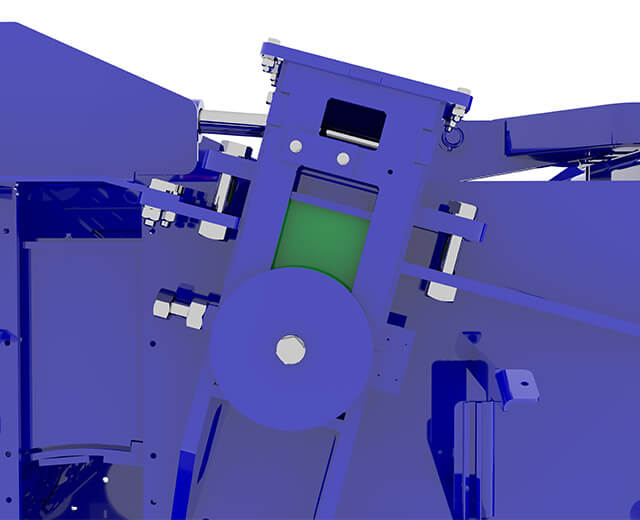

Rotor

Heavy duty and robust, the R+ rotor’s asymmetrical pattern of high & low bits create an aggressive shearing action with the comb grate.

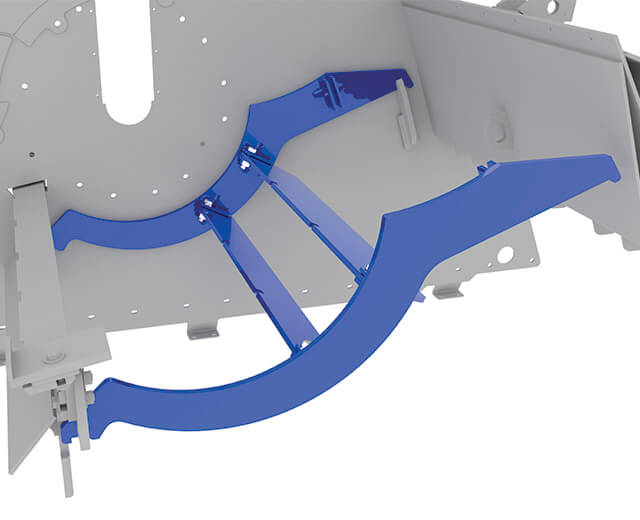

Comb Grate

The comb grate is a heavy-duty grate with additional shearing area, allowing material to be fractured across many surfaces. The three lower grate positions remain empty for material to easily exit the grinding chamber.

Tougher Impact Release System

The larger shear pin allows a dramatic increase of force needed to trip the Impact Release System.

Cushion blocks with increased hardness allows the Impact Release system to absorb harder hits.

Grate Supports and Baffle Plate

Modified grate supports allow for multiple baffle plate placements. Reinforced steel for heavier impacts from ejected materials.

Larger Sheave

The larger sheave decreases the rotor speed in half, allowing the rotor to sustain less damage from impact while creating more torque to efficiently power through heavy materials.

Heavy Duty Conveyor Belt

A heavy duty conveyor belt combinedwith an increased discharge clearance allows for larger volume of materials and superior belt life.

Air Bags

Air bags allow more materials to pass through the grinding chamber without unnecessary machine shutdowns, but still offers protection by opening the Impact Release System if an ungrindable object is encountered.

Downloads

Where to Buy

Find an Astec Dealer Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Construction & Demolition Recycling

Construction & Demolition Recycling materials include wood, cardboard, gypsum, plastic, metal, wire, roofing shingles, asphalt and concrete.

Learn More about Construction & Demolition Recycling

Municipal Solid Waste (MSW) Recycling

Grinding MSW is often part of the long-term plans for many landfills and municipalities to reduce MSW volume and fill rates, mitigate wear on machinery and help material decompose faster.

Learn More about Municipal Solid Waste (MSW) Recycling

Natural Disaster Cleanup

Natural disasters create debris that must be cleared to restore affected areas.

Learn More about Natural Disaster Cleanup

Railroad Tie Recycling

Expired or damaged railroad ties can be valuable for a variety of applications.

Learn More about Railroad Tie Recycling