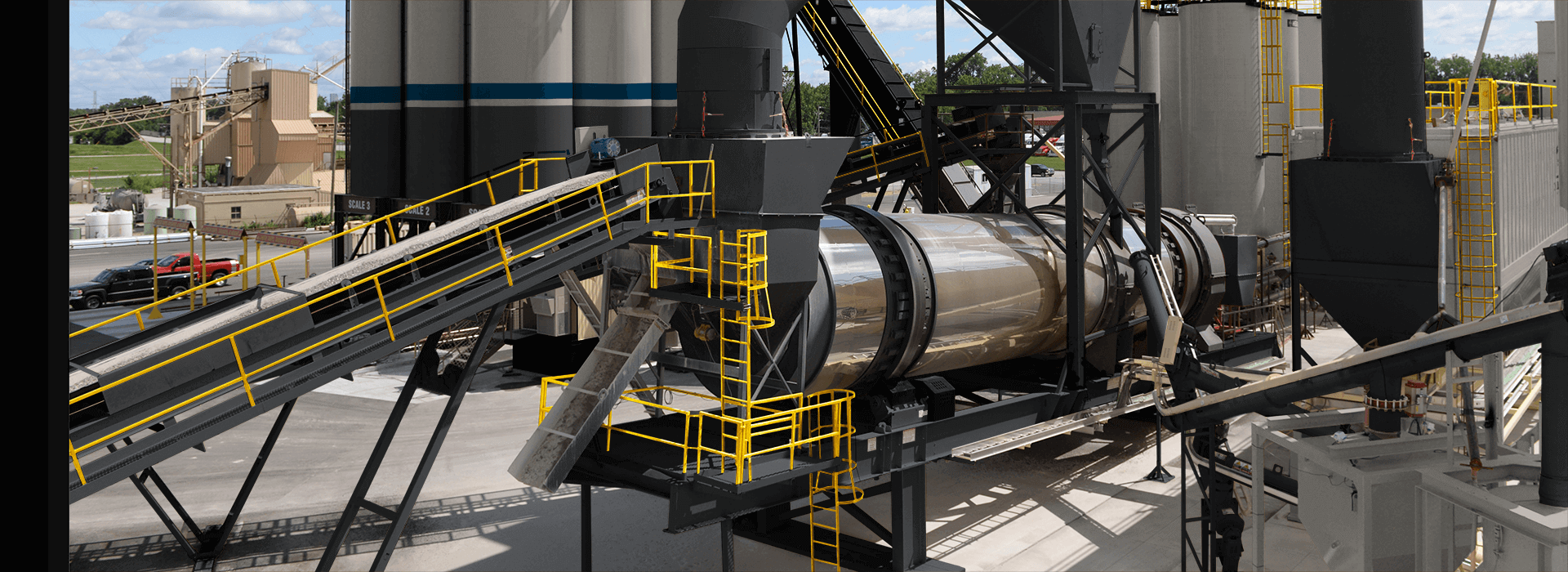

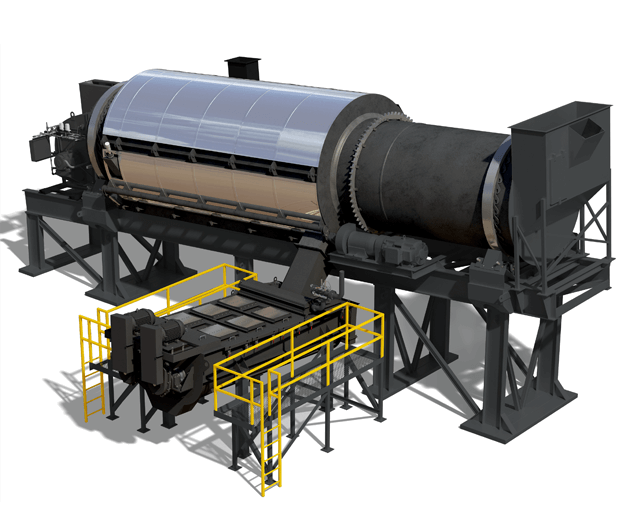

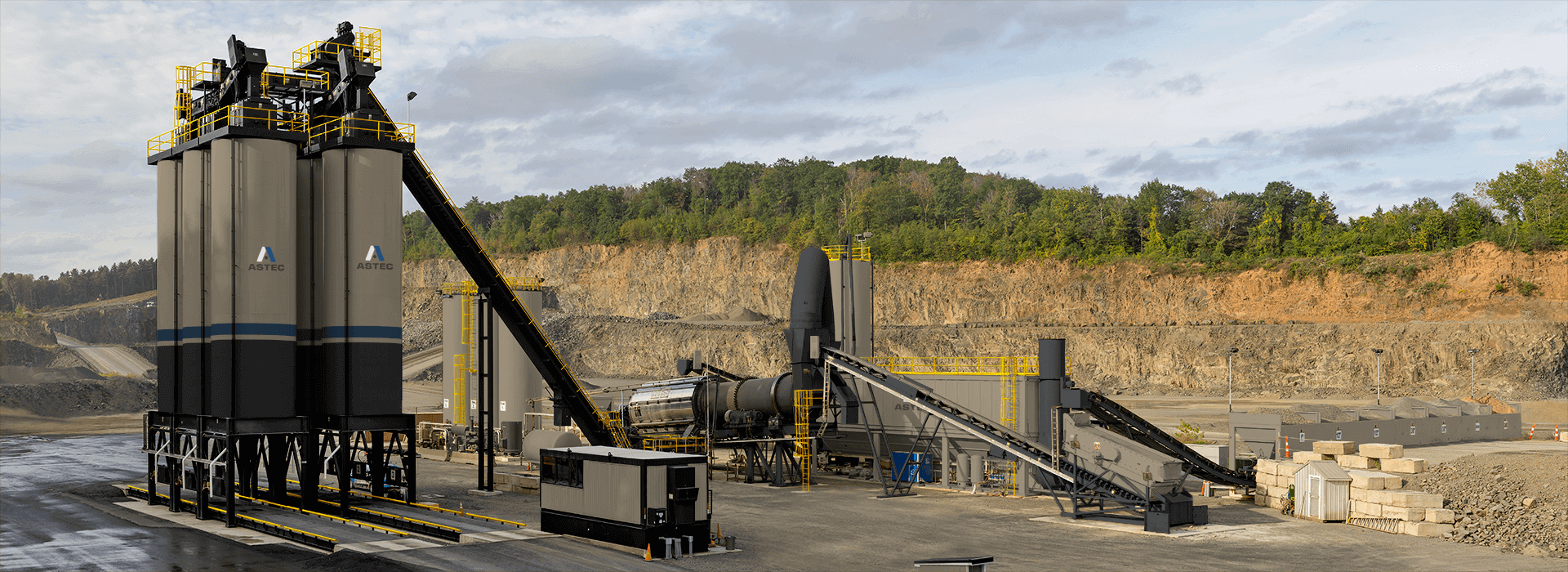

Astec Double Barrel® X Drum Mixer

The Double Barrel X system separates the drying process from the mixing process, thereby providing a very reliable tool to be used for the purpose of recycling reclaimed asphalt pavement (RAP).

Overview

Drum Dryer with External Mixer

The Double Barrel X system separates the drying process from the mixing process, thereby providing a very reliable tool to be used for the purpose of recycling reclaimed asphalt pavement (RAP). With a Double Barrel X system, a plant can process both warm and hot asphalt mixes with up to 50% RAP content while maintaining zero opacity at the stack.

The Double Barrel X technology allows for RAP to be pre-conditioned through the external part of the DBX dryer, flashing off moisture in the drum, thus eliminating the problems associated with scavenger systems.

Features

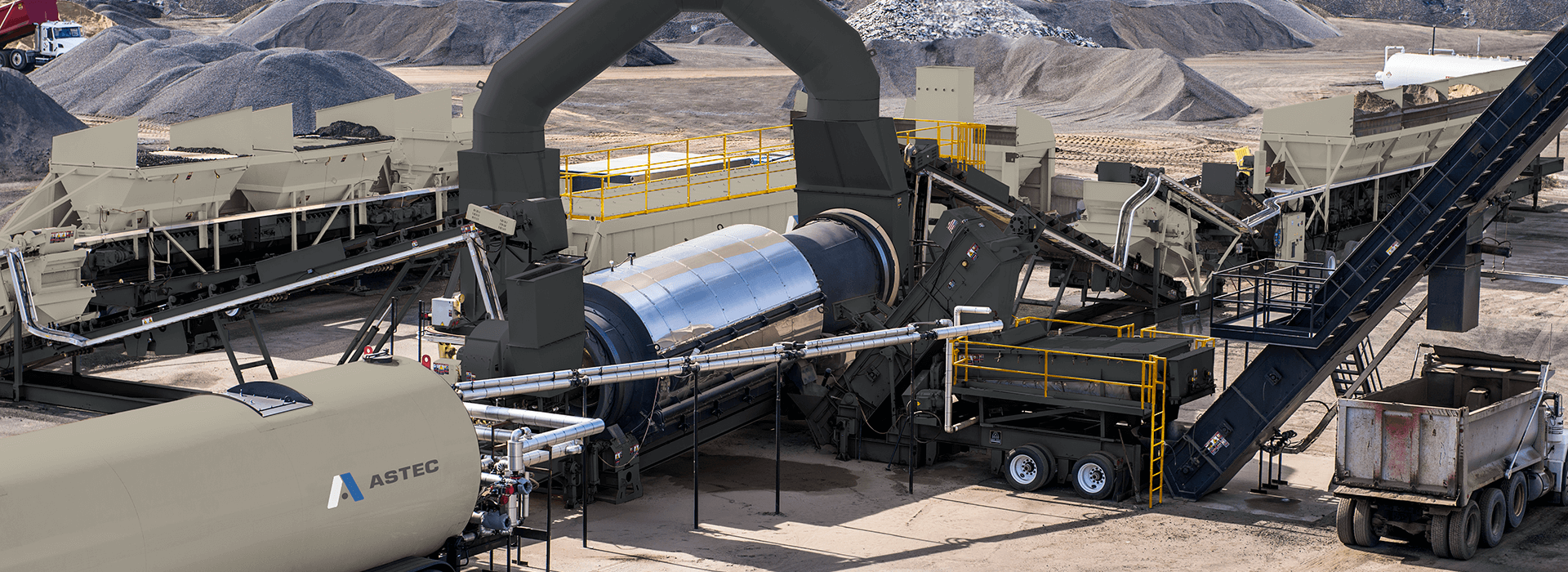

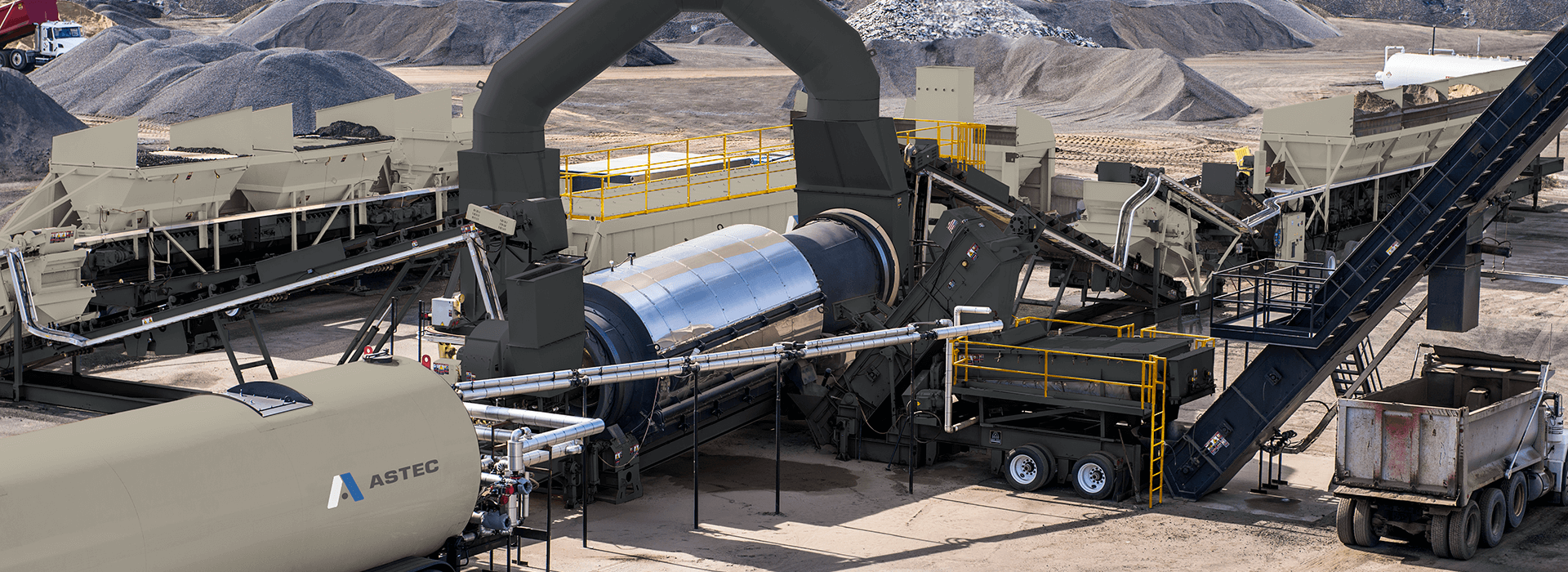

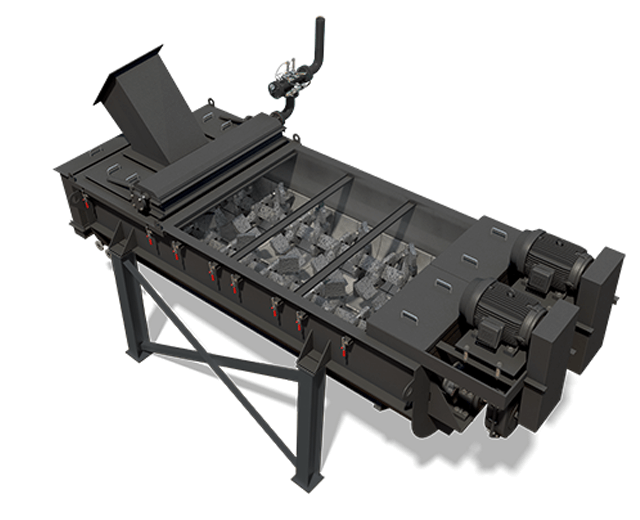

External Mixer

The Double Barrel X system separates the drying process from the mixing process to ensure proper mix quality and ease of drum maintenance.

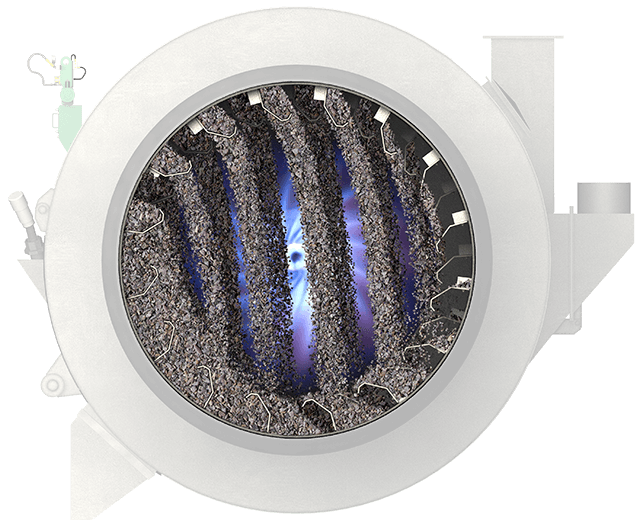

Twin-shaft Pugmill Mixer

After the heated and dried virgin aggregate thoroughly mixes with the RAP and fines, it passes out of the drum dryer/mixer and moves into an external pugmill. This is where liquid AC is added. Because the liquid AC only enters in the external mixer, virtually no build-up is produced in the dryer. With the addition of an optional Astec warm mix system, the Double Barrel X system produces warm mix asphalt.

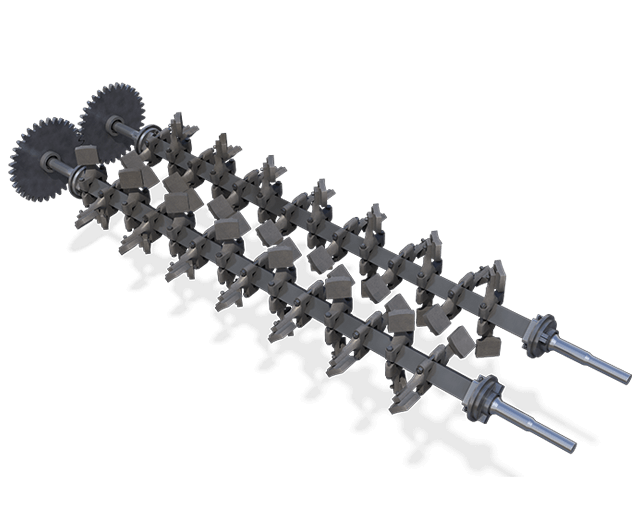

Counter-rotating Mix Paddles

Counter-rotating mix paddles of the external coater/mixer pugmill.

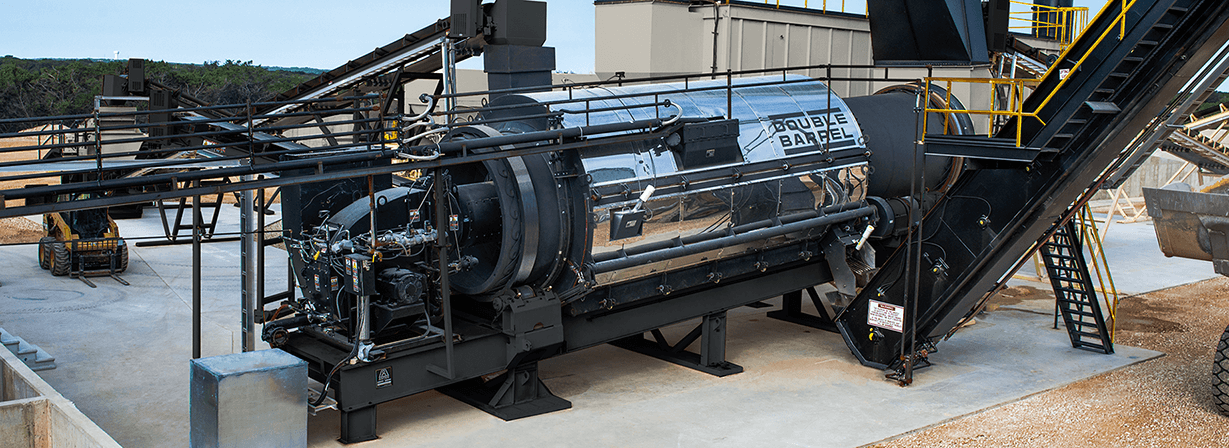

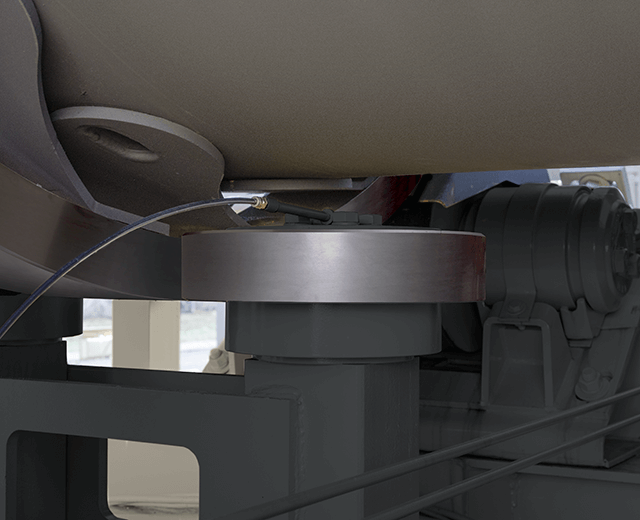

Double Barrel Hydraulic Access Door

A large hydraulically operated access door allows easy service of mixing shanks and tips from the outside of the drying drum.

Insulation

4″ thick insulation under the outer skin of the mixing chamber minimizes heat loss and increases efficiency. In addition, temperature-resistant ceramic fiber insulation is used in critical high-heat areas.

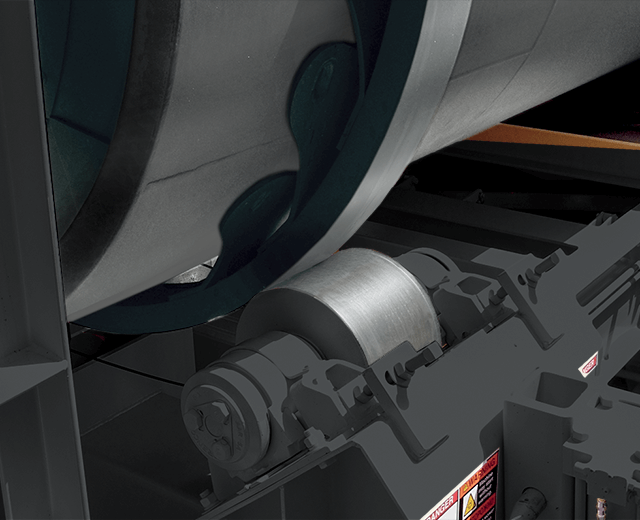

Double Barrel Thrust Rollers

Thrust rollers on either side of the tire restrain the drum.

Double Barrel Trunnions

Adjustable steel trunnions with railroad duty bearings.

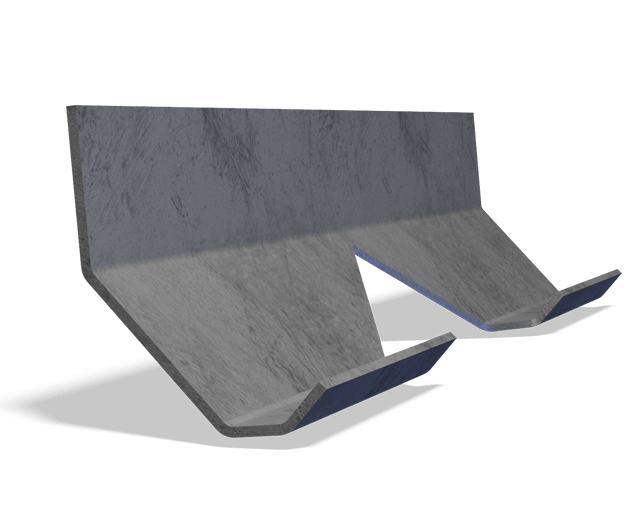

Double Barrel V-flight Veiling

Provides greater uniformity of the aggregate veil through the gas stream during the drying process, across a wide variety of mix designs and tonnage rates.

Astec V-flight

The v-shaped notch allows material to start pouring out of the bucket at the beginning of each revolution. The material in the bucket continues to pour out until the rotation is complete. This is what provides an even veil of material. The v-flight is also larger than a traditional flight, allowing it to carry the same amount of aggregate even with the notch.

Downloads

Where to Buy

Find an Astec Contact Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Asphalt Mixing

Astec produces a complete line of asphalt mixing plants, and its range of capacities and features gives you the choices and flexibility to create your optimum plant.

Learn More about Asphalt Mixing

Recycled Asphalt Pavement

Recycled asphalt pavement (RAP) is asphalt paving material recovered from old road beds either by milling or excavation.

Learn More about Recycled Asphalt Pavement