Peterson 4300B Drum Chipper

The 4300B drum chipper is suited for high volume biomass producers who have a wide variety of feed material, from logs up to 26 inches (61 cm) in diameter, to brush and small feedstock.

Overview

The 4300B drum chipper is suited for high volume biomass producers who have a wide variety of feed material.

The 4300B drum chipper can easily handle material from logs up to 26 inches (61 cm) in diameter, to brush and small feedstock.

The chipper utilizes a 36 inch diameter by 40 inch wide (91 by 102 cm) drum with wear resistant AR450 wear surfaces on the drum pockets and shell. A sloped feed deck makes feeding the chipper easier. The optional material sizing bars and chip accelerator minimize oversize twigs and branches in the chips, and

help ensure tight chip packing and fully loaded chip vans.

Features

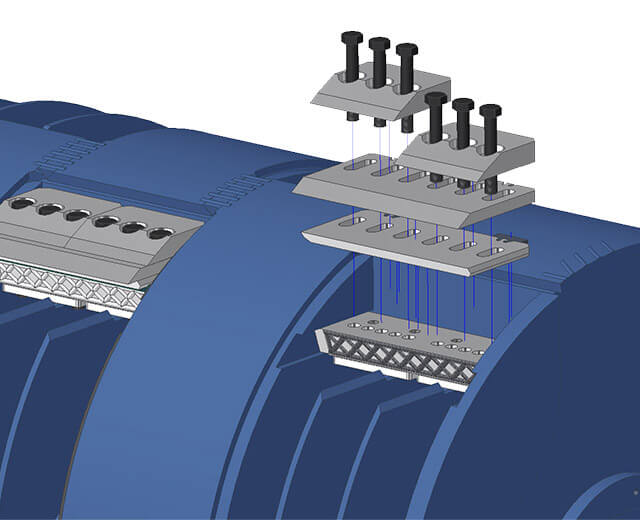

Knife Assemblies at the Heart of the Chipper

Produced from the highest quality alloy chromium steel, heavy-duty Astec knife assemblies achieve uniform production of woodchips with high accepts and minimal losses.

Select From 6- or 12-Pocket Drum

Featuring durable AR400 wear surfaces, the 4300 series Drum Chippers comes standard with an 6-pocket drum rotor with one Babbitted knife per pocket. A 12-pocket drum rotor is available for chipping microchips.

Discharge Spout Options

Two discharge spouts are available on all Peterson Drum Chippers. An end-load spout designed to load closed-top chip vans. A top-load discharge spout is also available and designed to load open-top chip vans.

Superior Product Sizing

Peterson’s drum chipper grate system provides ultra-consistent chip sizing; twigs and small stems which can be difficult to size are easily fractured through our innovative system. The chipper grate is located next to the chipper drum and ensures that materials passing through the grate meet a specific size requirement.

Downloads

Specifications

All specifications subject to change without notice.

Where to Buy

Find an Astec Dealer Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Aggregates

There are two main classes of aggregates: natural and manufactured.

Learn More about Aggregates