Heatec Booster Heater

Heatec Booster Heaters are used when liquids, such as liquid asphalt (bitumen), are stored at a lower temperature than what is needed for the end user. These types of heaters are found at asphalt terminals and roofing products manufacturing facilities.

Overview

Heatec Booster Heaters are used when liquids, such as liquid asphalt (bitumen), are stored at a lower temperature than what is needed for the end user. Booster heaters work by circulating the liquid through the heater to increase the temperature before the liquid is loaded for transport or sent to its end user. These types of heaters are frequently found at asphalt terminals, roofing manufacturing facilities, gas processing facilities and more.

Heatec builds different types of booster heaters: fired heaters, heater/exchanger combination, or an electric heater. All come in a variety of sizes and are customizable.

Features

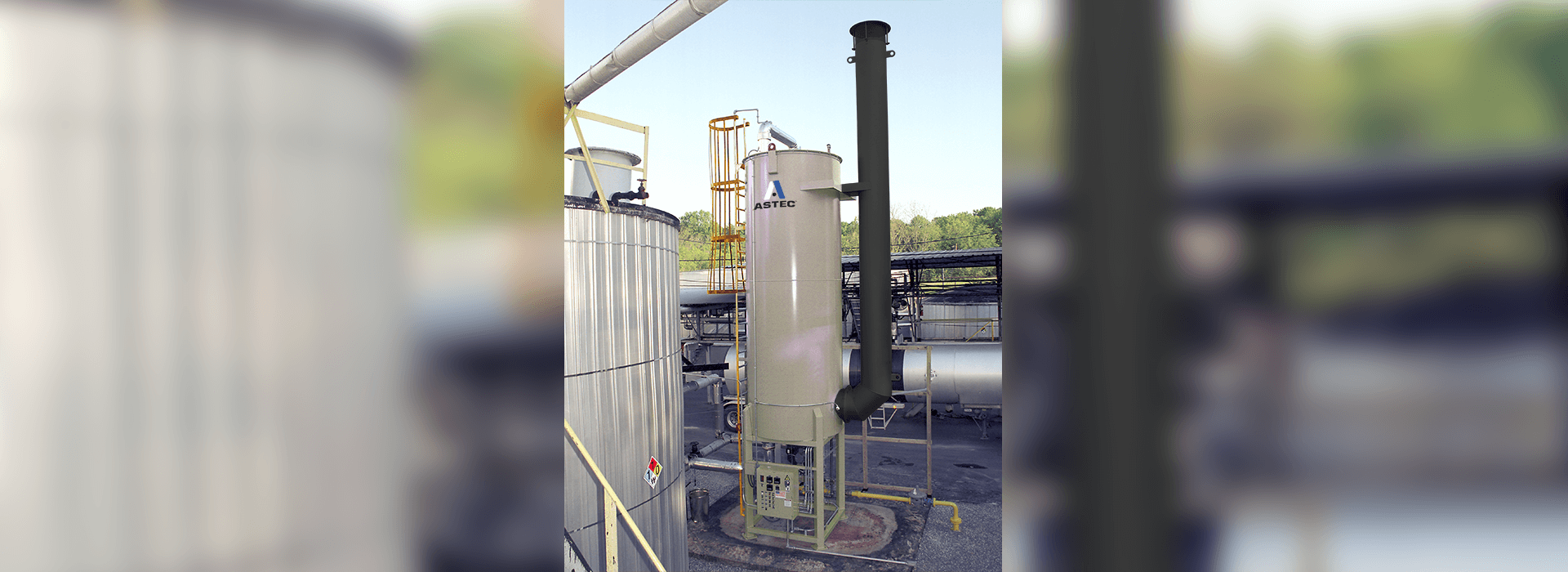

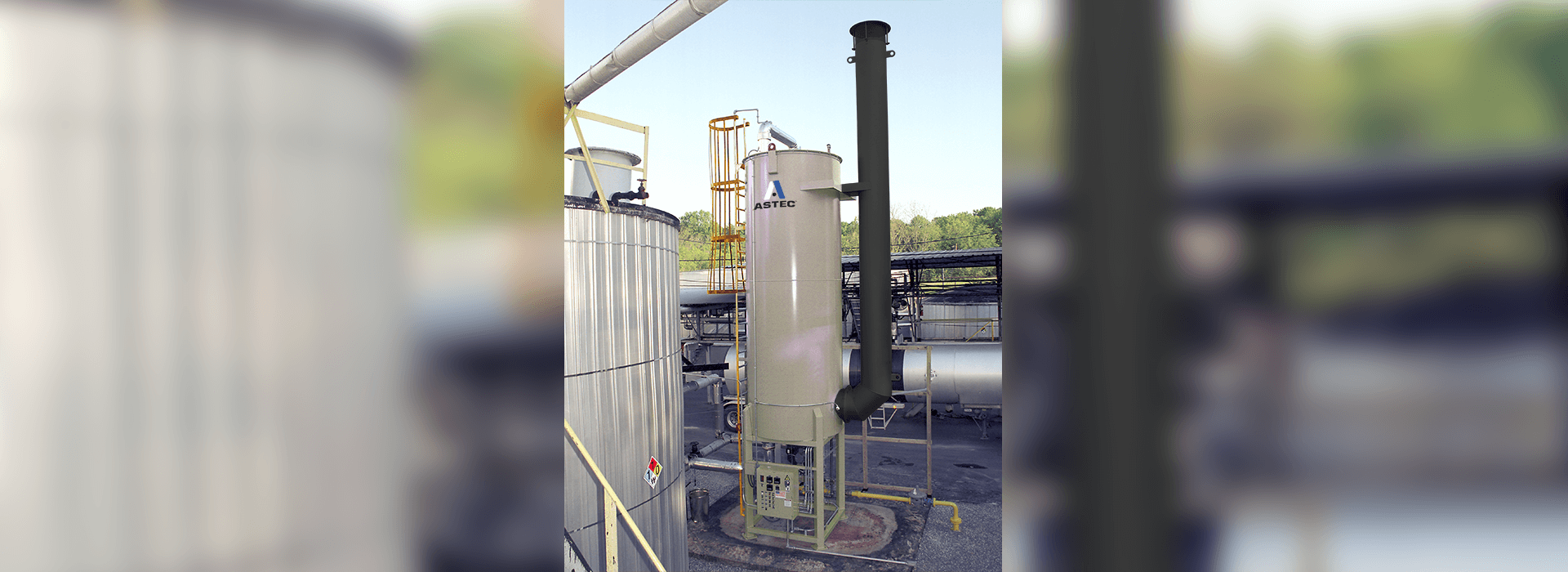

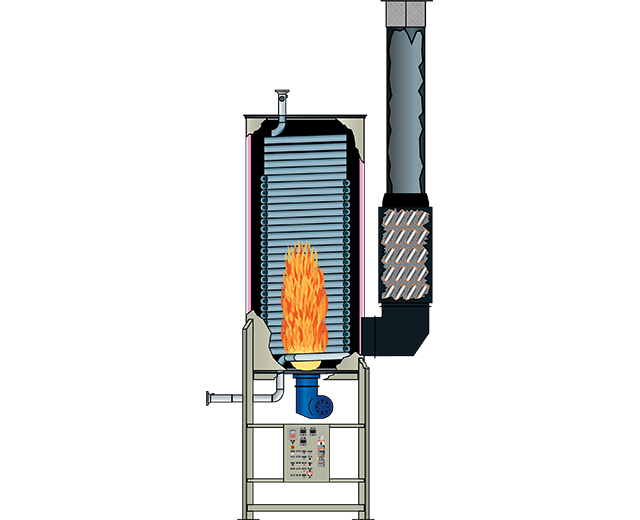

Heatec Fired Booster Heater

Typical Heatec fired booster heaters are designed around a helical coil. Serpentine coils are also available. The liquid circulates through the coil and is heated by hot gases from a flame produced by a burner. The heater is typically constructed in a vertical orientation to allow for the liquids to be easily drained from the coil. This prevents the liquid from pooling and possibly hardening in the coil when it’s not in use. An optional economizer can be added to increase efficiency of the heater.

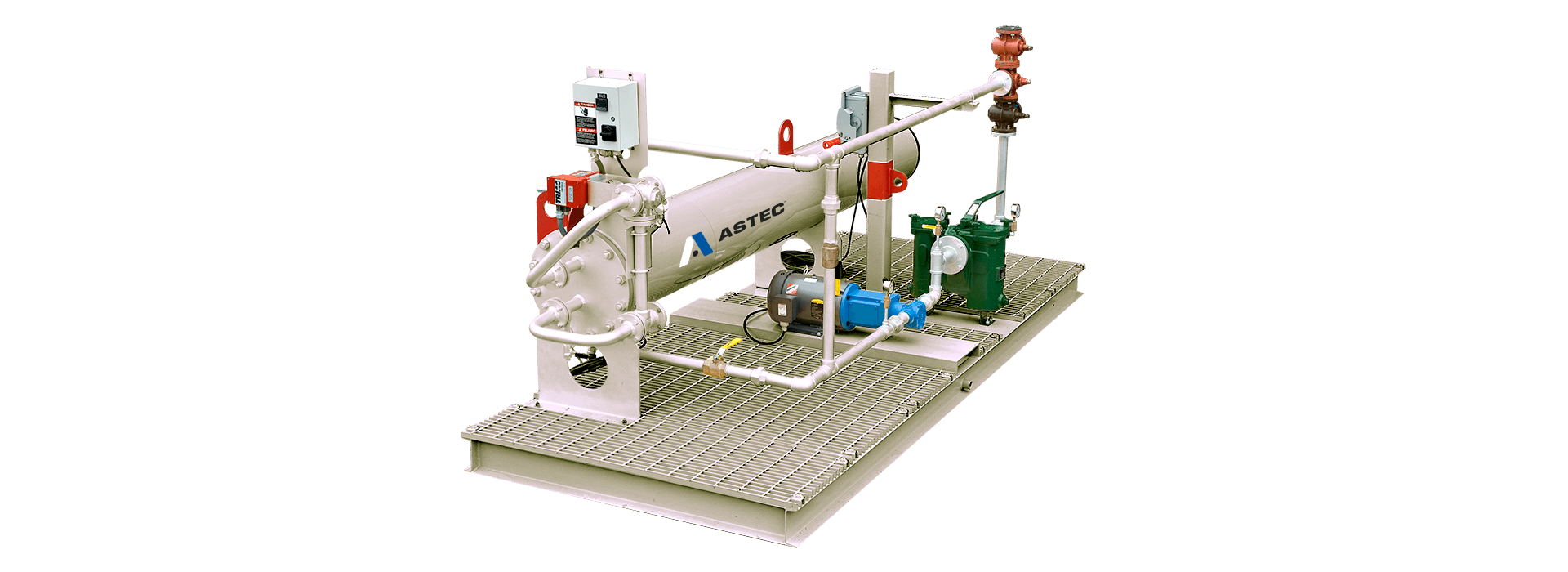

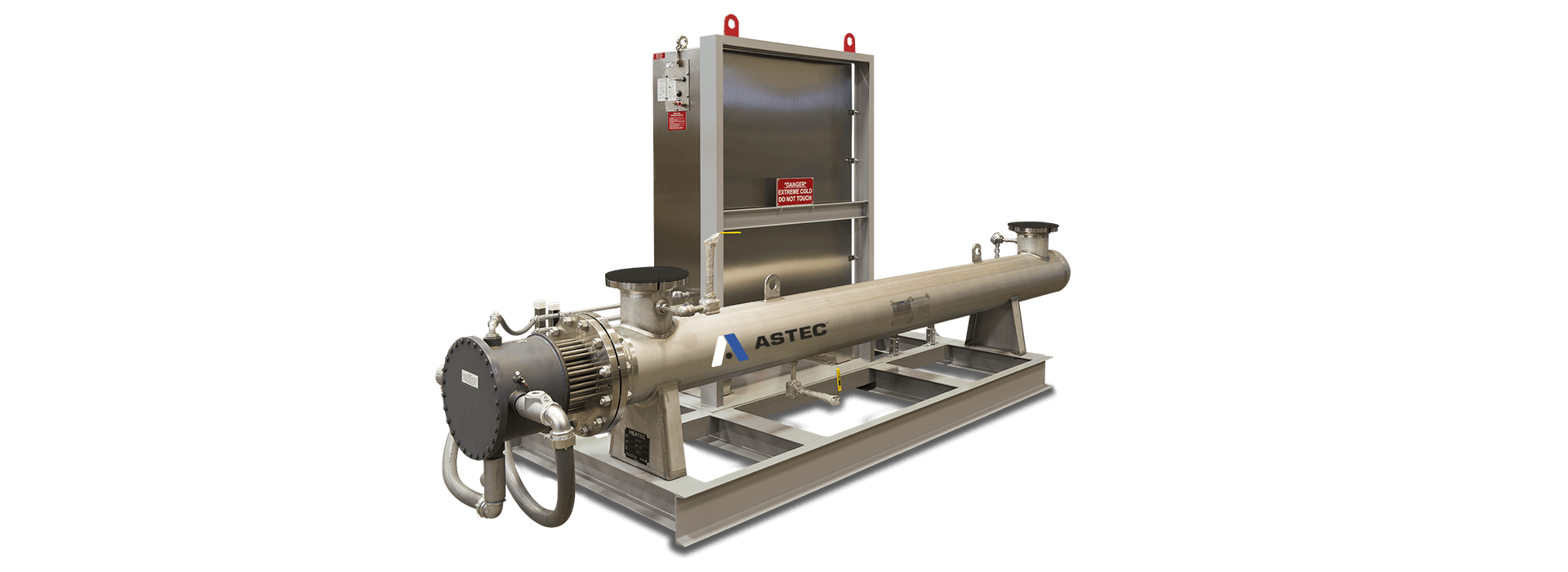

Heatec Booster Heater Exchanger

A heat exchanger can be used in place of a fired booster heater if you already have a thermal fluid heater at your facility or you need the thermal fluid heater to heat other users as well. For example, when you are using a thermal fluid heater to heat your tanks at an asphalt terminal and you need to boost the heat a little for polymer blending at the same facility you would add an exchanger to your system. The exchanger uses thermal fluid from the heater as its source of heat.

Where to Buy

Find an Astec Contact Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

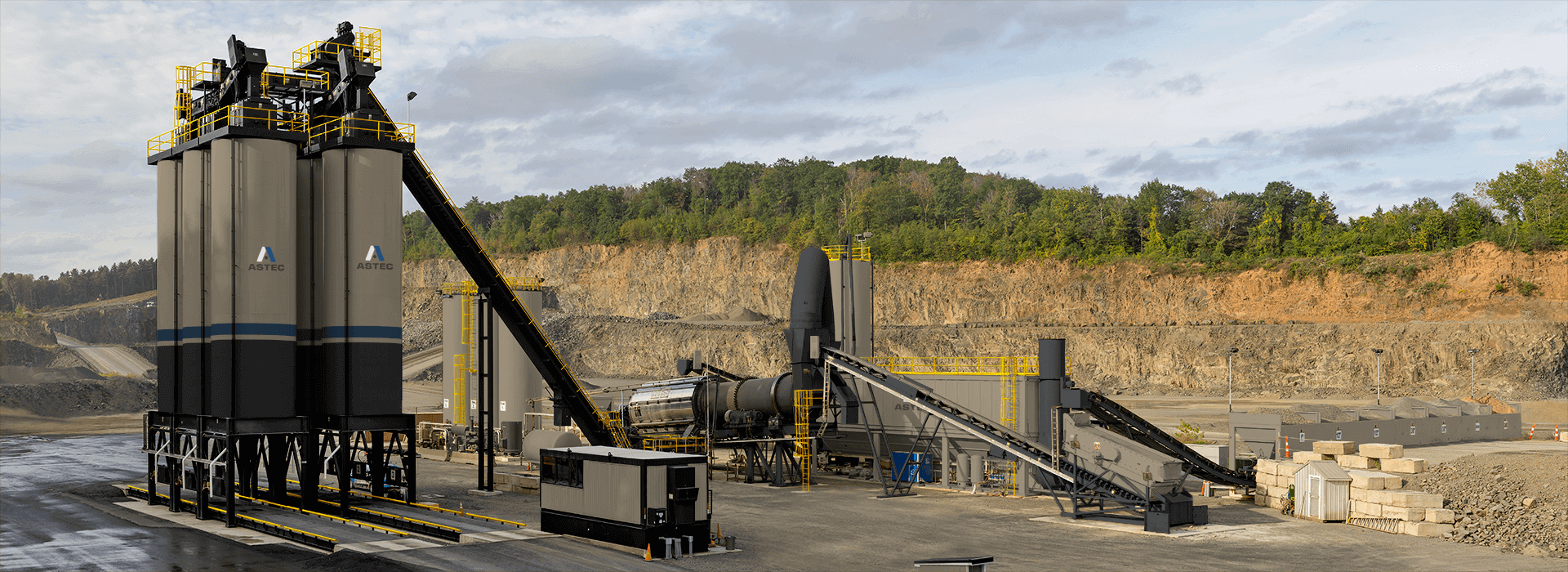

Asphalt Mixing

Astec produces a complete line of asphalt mixing plants, and its range of capacities and features gives you the choices and flexibility to create your optimum plant.

Learn More about Asphalt Mixing

Crude Oil & Natural Gas Processing

Refining and processing crude oil and natural gas require highly reliable and efficient heating systems and services.

Learn More about Crude Oil & Natural Gas Processing

Roofing & Construction Products

Astec has an extensive background in supplying equipment to the asphalt/roofing industry heating such as liquid asphalt storage as well as experience with all types of thermal systems.

Learn More about Roofing & Construction Products