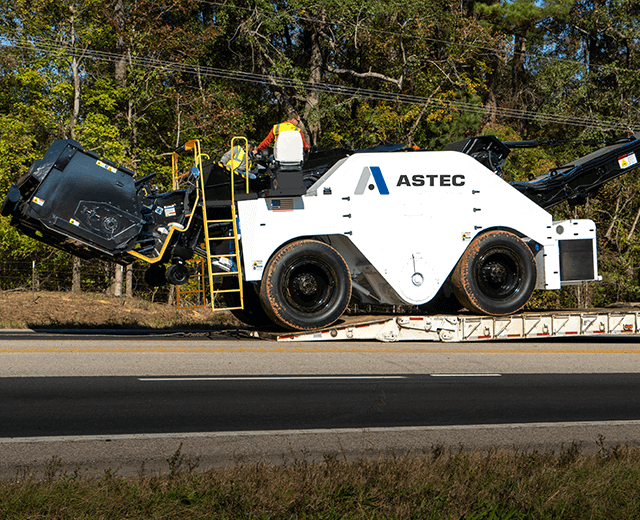

Roadtec SB-3000 Shuttle Buggy® Material Transfer Vehicle

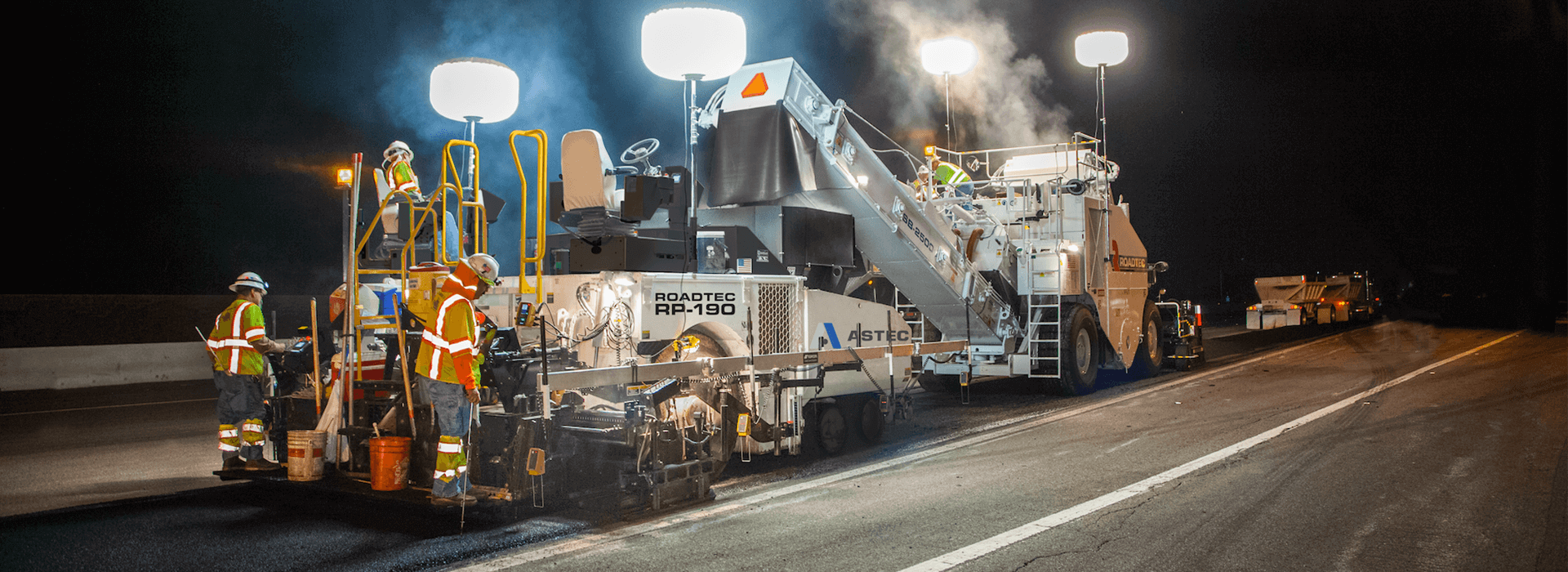

The SB-3000 Material Transfer Vehicle is a powerful yet maneuverable MTV that stores and transfers hot-mixed asphalt material from truck to paver for non-stop paving while enhancing safety, comfort, and productivity.

Overview

The SB-3000 offers simple maintenance access and ideal operator comfort.

The Shuttle Buggy 3000 Material Transfer Vehicle (MTV) is an efficient and productive MTV. The powerful yet maneuverable SB-3000 provides a quality mat without sacrificing comfort, safety, or efficiency. Features include easy maintenance access, a tight turning radius, bright lighting, nimble steering, and high visibility cameras. The SB-3000 has a 25-ton storage capacity and is powered by a Stage 5, Cummins® B6.7 engine.

Features

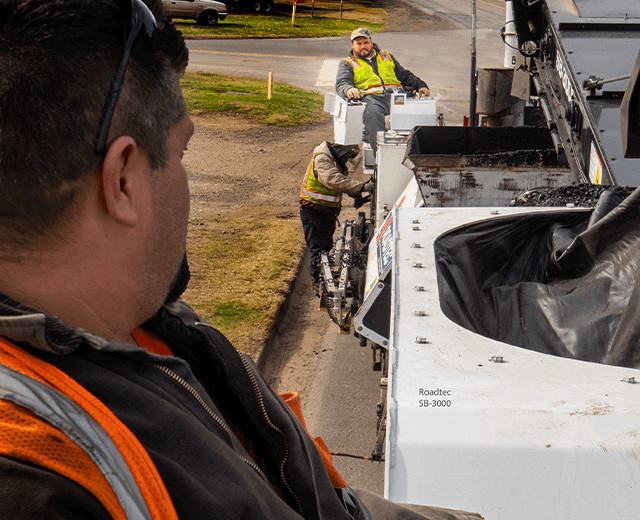

Ground Crew Control Panel

- Panel swings out for use when standing, and swings in when sitting within the safety envelope of the machine

- Whether seated or standing, the ground operator is in control via the easy to use panel.

- Maximizes the efficiency and safety of the ground operator

- Maintains focus on comfort and productivity

Quick Change Conveyor

- Ideal for those who need to switch back and forth from dump hopper to windrow hopper

- Change to windrow head from dump hopper in hours, rather than days

- Easy to keep spare head pieces together

- Easier access for maintenance, changing chains, and maintaining augers

Ideal Operator Visibility

- Operator can clearly see in front of the machine and down to the auger box

- While seated, operator has an unobstructed view of the ground person

- Unobstructed view of work area

Backup Camera

- Allows the operator to see behind the machine when in reverse

- Camera automatically turns on when in reverse

- Images are clearly displayed in real-time on multiple screens mounted to the machine

- Can be accessed any time through the touch screen

Dual Function Ladder

- Provides access to the operator station and also acts as a bridge across the machine

- Bridge allows the crew to travel to either side of the roadway without having to cross between machines, improving safety and keeping the mat clear

- Operator station can be accessed from either side

- Manufactured to ISO standards

- Angled to 80 degrees, making it easier to mount and dismount

Truck Signal Lights

- Illuminated indicators that clearly communicate with dump trucks

- Help dump truck operator know exactly what to do to keep the job moving and the crew safe

- Lights are built into the base of the operator seats

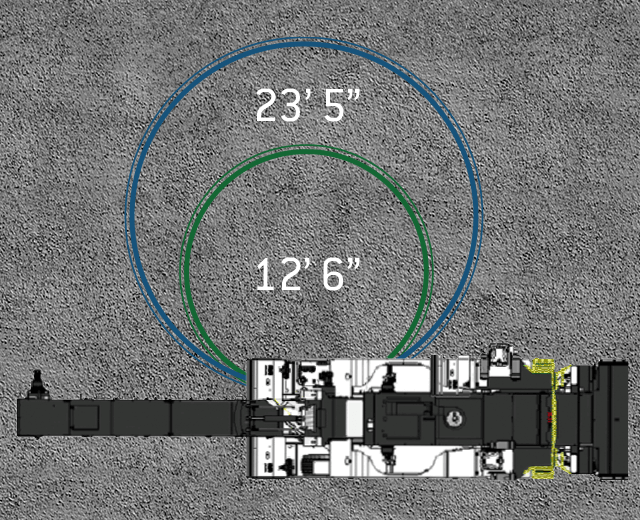

Agile Steering

- Four steering modes enhance agility

- Ability to maneuver through tight turns

- Steering modes include crab, coordinated, rear only, and front only

- When in front steering mode, the SB-300 can turn on an inside radius of 23’ 5”When in coordinated mode, the turning radius is just 12’6”

Simple Trailer Transport

- Four-wheel steer simplifies trailer loading and unloading

- Shipping height of 11’ 3” facilitates faster and easier transport, with less cost

- Shipping height allowing flexibility when selecting a trailer

- Never a need to manually raise or lower the Fume Extraction System® (FXS) exhaust, even during transport

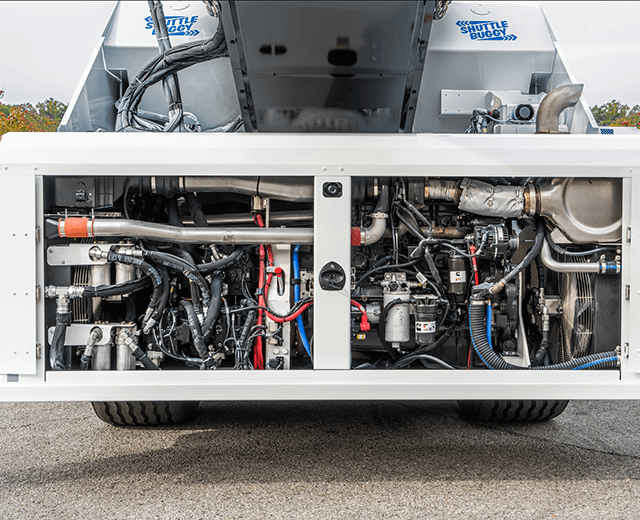

Ground Level Engine Access

- Engine is at ground level so daily inspections and maintenance can be performed safely and easily

- Large barn doors at the rear provide access to the engine on one side, and the hydraulic pumps on the other

- Easy to reach panels on either side of the SB-3000 provide simple access to convenient storage areas

Dump Hopper Landing Lights

- Projector displays blue guidelines on the ground

- Landing lights serve as guides for trucks to follow toward the dump hopper

- Facilitates clear communicate with dump trucks

- Promotes safe and efficient night work

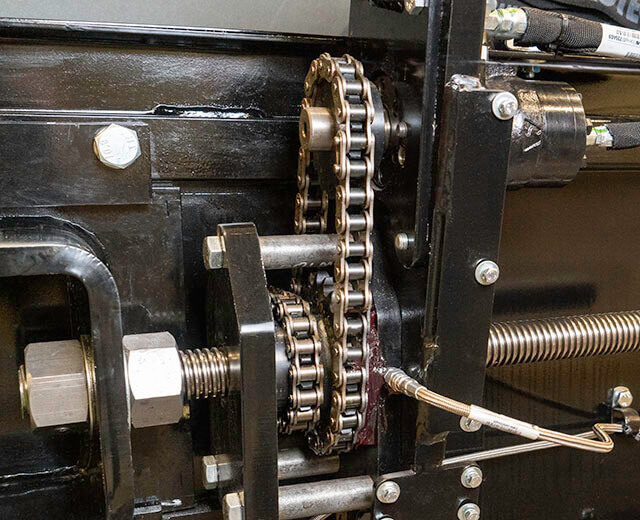

Power Chain Tensioning

- Hydraulically powered chain tensioning

- Enables user to easily monitor and adjust the tension of all three conveyors without leaving the ground

- Improves safety, speed, and efficiency

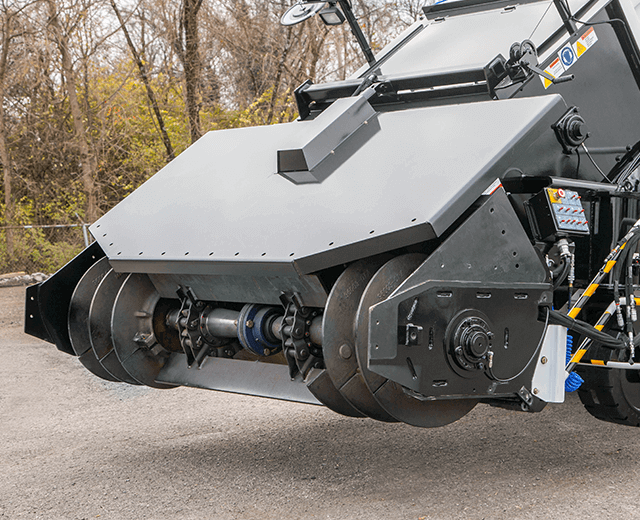

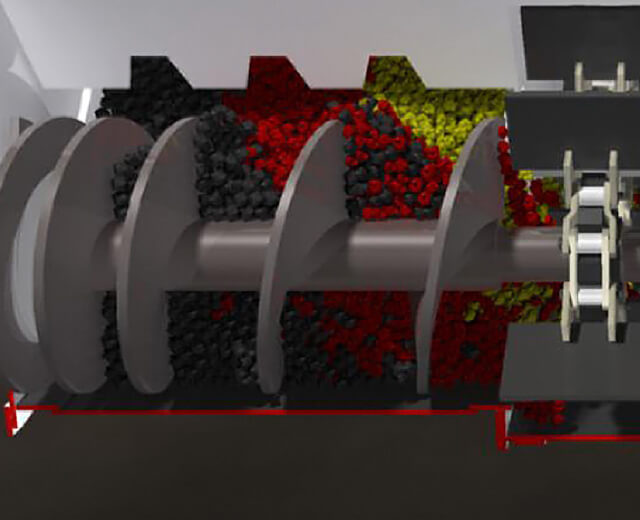

Shuttle Buggy Triple Pitch Augers

- Triple pitch augers located in the main storage hopper provide consistent and uniform mixing and blending

- Reduce the common issues of thermal and material segregationcaused by single pitch augers

- Sized to remix the material while keeping the conveyor chain out of the mix

Guardian Telematics

- Monitors machines in real time through a wireless signal

- Industry’s only live 2-way telematics system

- Includes software, on-machine viewing screens and wireless signal boosters to send and receive data in real time

- Intuitive Live Schematics™ let owners and technicians view electrical circuits in a simple, efficient layout with real time status of switches, valves and settings

Downloads

Specifications

|

Imperial (in) |

Metric (mm) | |

|---|---|---|

|

Engine MFG |

Cummins QSB 6.7 |

Cummins QSB 6.7 |

|

Weight |

77190 lb |

35012 kg |

|

Dump Hopper Unloading Conveyor Capacity |

1000 TPH |

907 MTPH |

|

Max Power |

310 hp @ 2,000 rpm |

231 kW @ 2,000 rpm |

|

Suspension |

21″ x 35″ High-Flotation Tire |

533 mm x 889 mm High-Flotation Tires |

All specifications subject to change without notice.

Where to Buy

Find an Astec Dealer Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Highway Paving

Highway class paving projects are large scale and can include interstates, expressways and superhighways.

Learn More about Highway Paving