Astec Blue Smoke System

The Astec fiberbed mist collector is an efficient solution for capturing and cleaning blue smoke from silo or loadout operations. Our fiberbed mist collectors offer distinct advantages that ensure reliable operation, low maintenance, and long filter life.

Overview

Blue smoke is the leading cause of odor complaints at an asphalt facility. Reducing fugitive blue smoke emissions will decrease the level of detectable odors from your facility and improve your work environment as well as community relations.

Blue smoke is the result of asphalt fumes condensing upon contact with cool ambient air. To minimize emissions, it is necessary to control the condensation of the asphalt fumes.

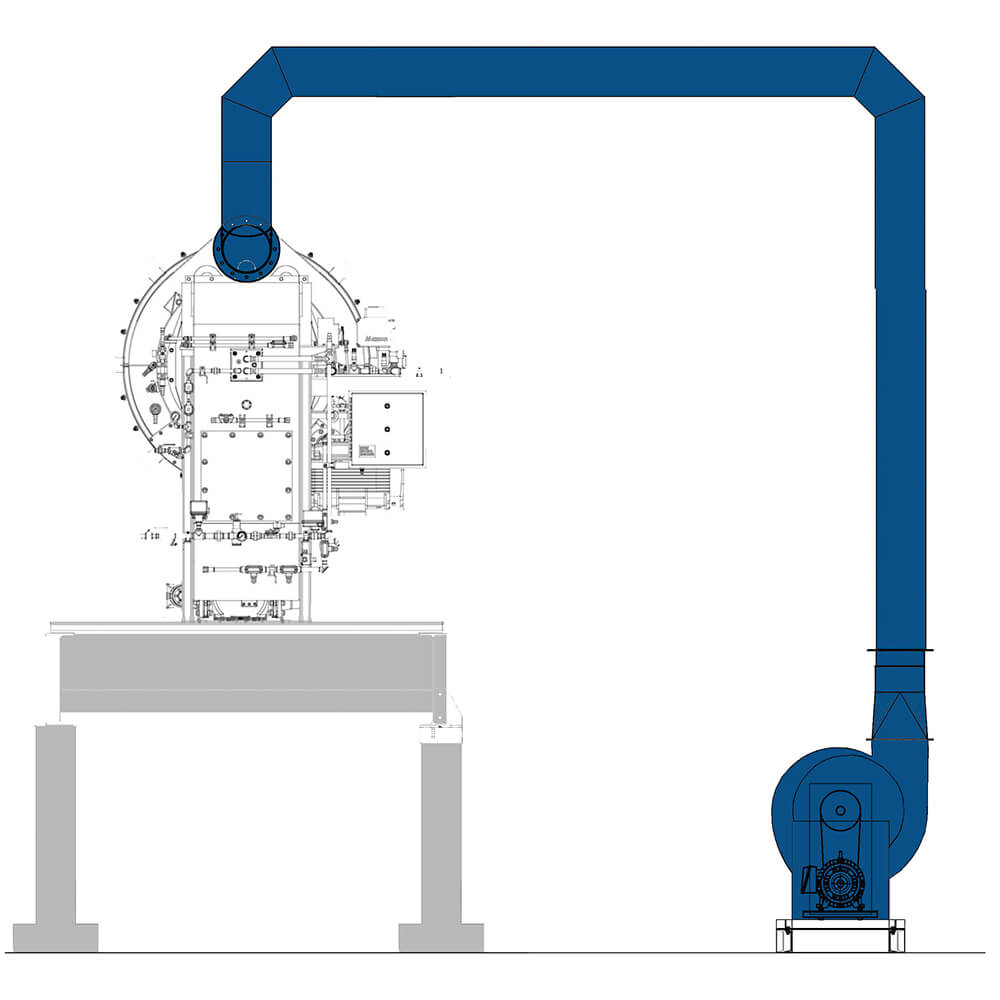

The Astec Blue Smoke System includes a network of scavenge ductwork and collection points designed to control emission opacity by limiting the escape of vaporized asphalt fumes into the atmosphere.

Features

Asphalt Fume Disposal Incineration

Blue smoke system configuration varies based on the method of asphalt fume disposal: incineration or filtration. Asphalt fumes released from the silo are pulled through the ductwork by a radial blade centrifugal fan and directed to the burner for incineration. The main system exhaust fan pulls the asphalt fume-laden air into the flame of a total air burner. The captured smoke is ejected from a dispersion ring encircling the burner and the smoke particles are blown directly into the flame.

Asphalt Fume Disposal Filtration

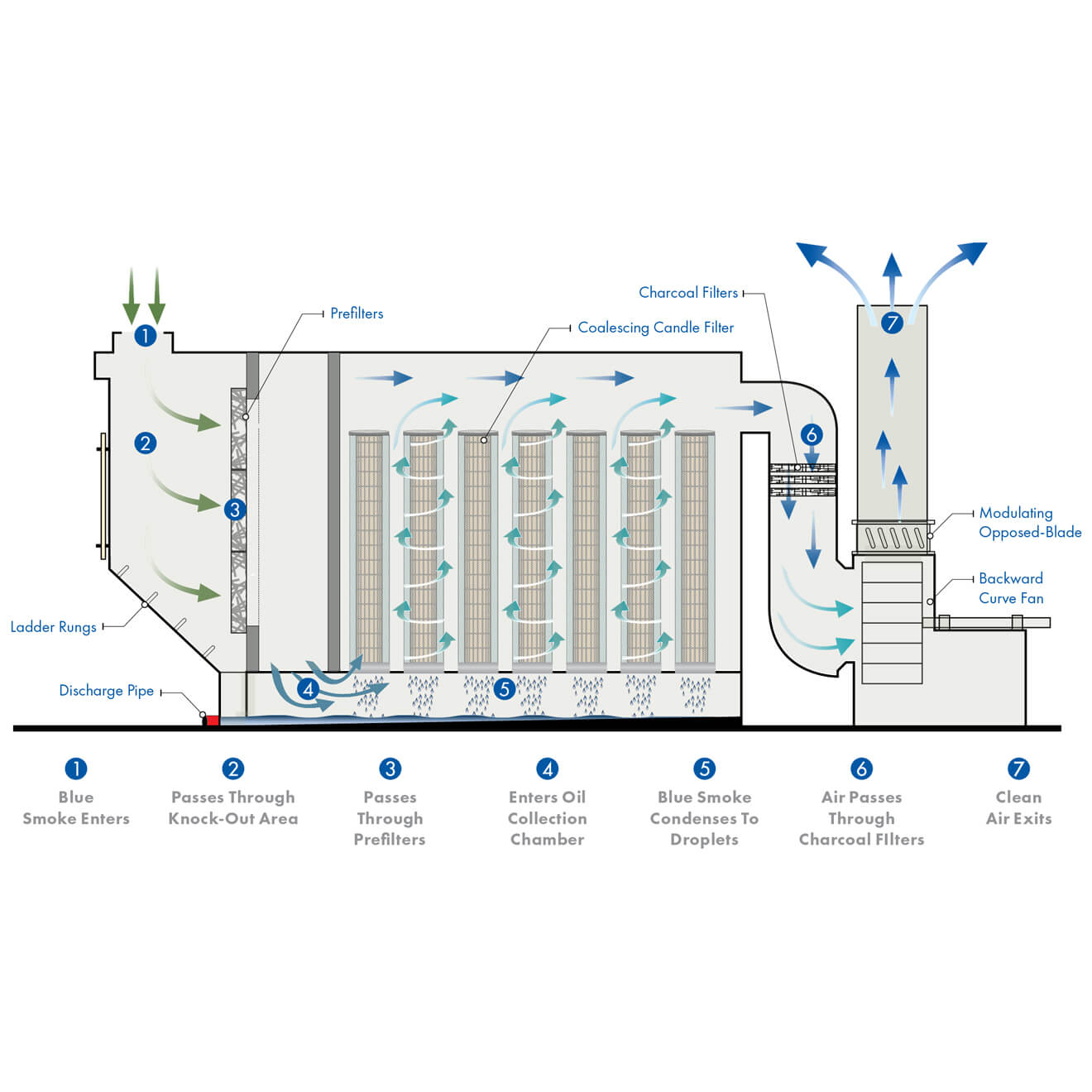

With the Astec blue smoke system, asphalt fumes from the silo filling and loadout operations condense within the fiberbed mist collector rather than in the atmosphere. Prefilters and coalescing candle filters within the unit filter particulate matter from the gas stream. The goal is to keep the blue smoke compounds above the dew point until they reach the inlet of the fiberbed unit.

Fiberbed Mist Collector

The Astec fiberbed mist collector is an efficient solution for capturing and cleaning blue smoke from silo or loadout operations. Our fiberbed mist collectors offer distinct advantages that ensure reliable operation, low maintenance, and long filter life.

Blue Smoke System Ductwork

Blue smoke system duct routing is customized to suit the facility configuration.

Doors for inspection and clean-out are located in all duct branches.

Blue Smoke System Tunnel

A tunnel enclosing the entire loadout area is required for proper collection.

While Astec does not provide the tunnel, we do provide suggestions based on the needs for the individual operation.

Astec Fiberbed Mist Collector Easy Maintenance

Designed with maintenance in mind, the Astec Fiberbed Mist Collector eliminates much of the mess and the hassle of filter changes and inspections.

Astec Fiberbed Mist Collector Clean Exhaust

The existing air will have less than 5% opacity. Cleaning efficiency of the system is as high as 99.99%, based on particle size and compounds in the gas stream.

Fiberbed Mist Collector Safety Features

Inlet temperatures are monitored by a sensor. On the smallest unit a fresh air damper is automatically activated if temperatures exceed 120° F. Larger units pull sufficient ambient air to keep the inside of the unit cool. All units have fire suppression safeguards in case of malfunction.

Fiberbed Mist Knock-out Area and Prefilters

- Blue smoke emissions from mix transfer operations are routed through ducting to the collector.

- A large knock-out area at the front of the unit allows particle matter to drop out of the gas stream before the prefiltering process.

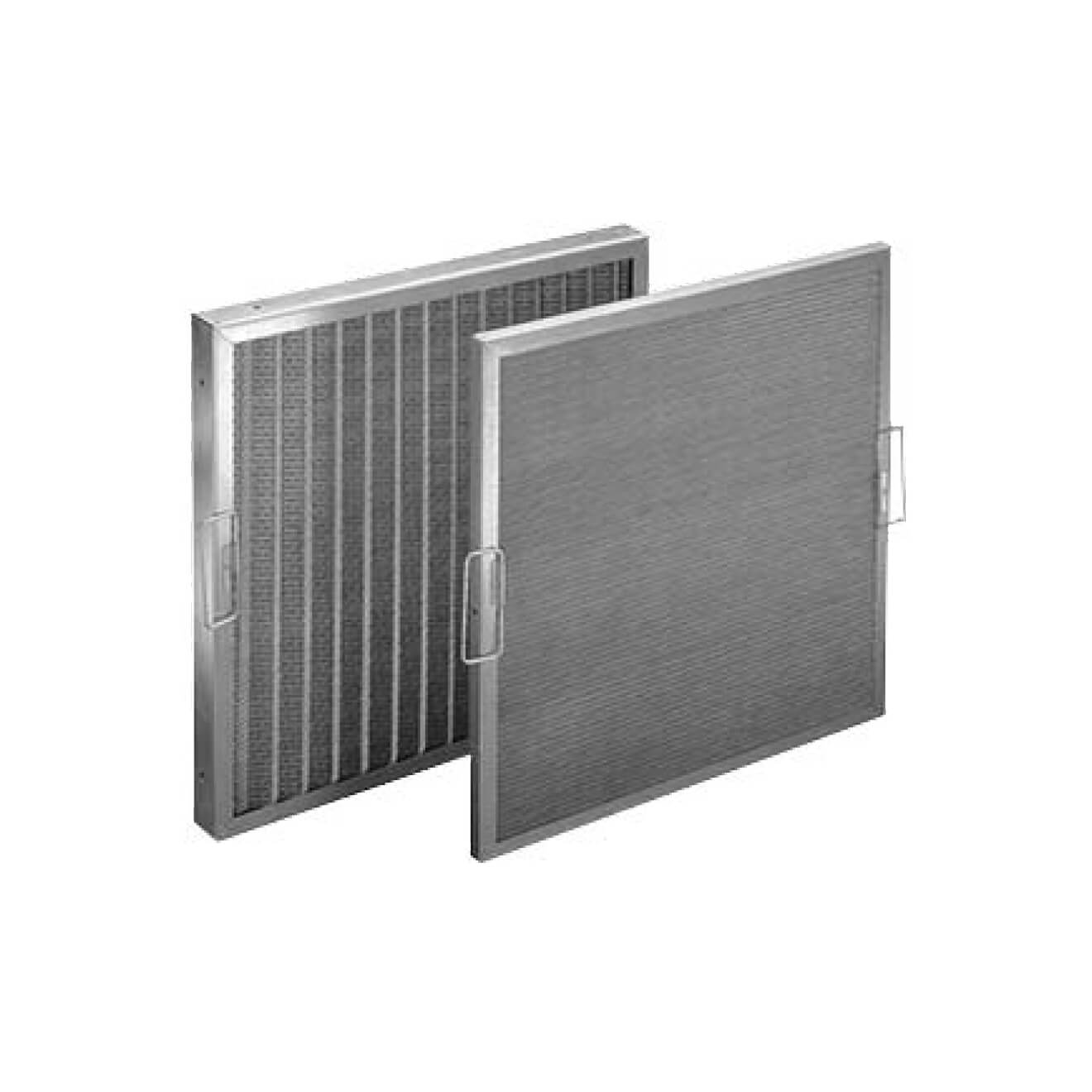

- The gas stream enters the enclosure and passes through prefilters.

- Solid particulate matter in the gas stream is captured by the prefilters. Removing these particles significantly lengthens the life of the filter media in the coalescing section.

- The Astec prefilter is completely washable and may be cleaned several times before needing to be replaced.

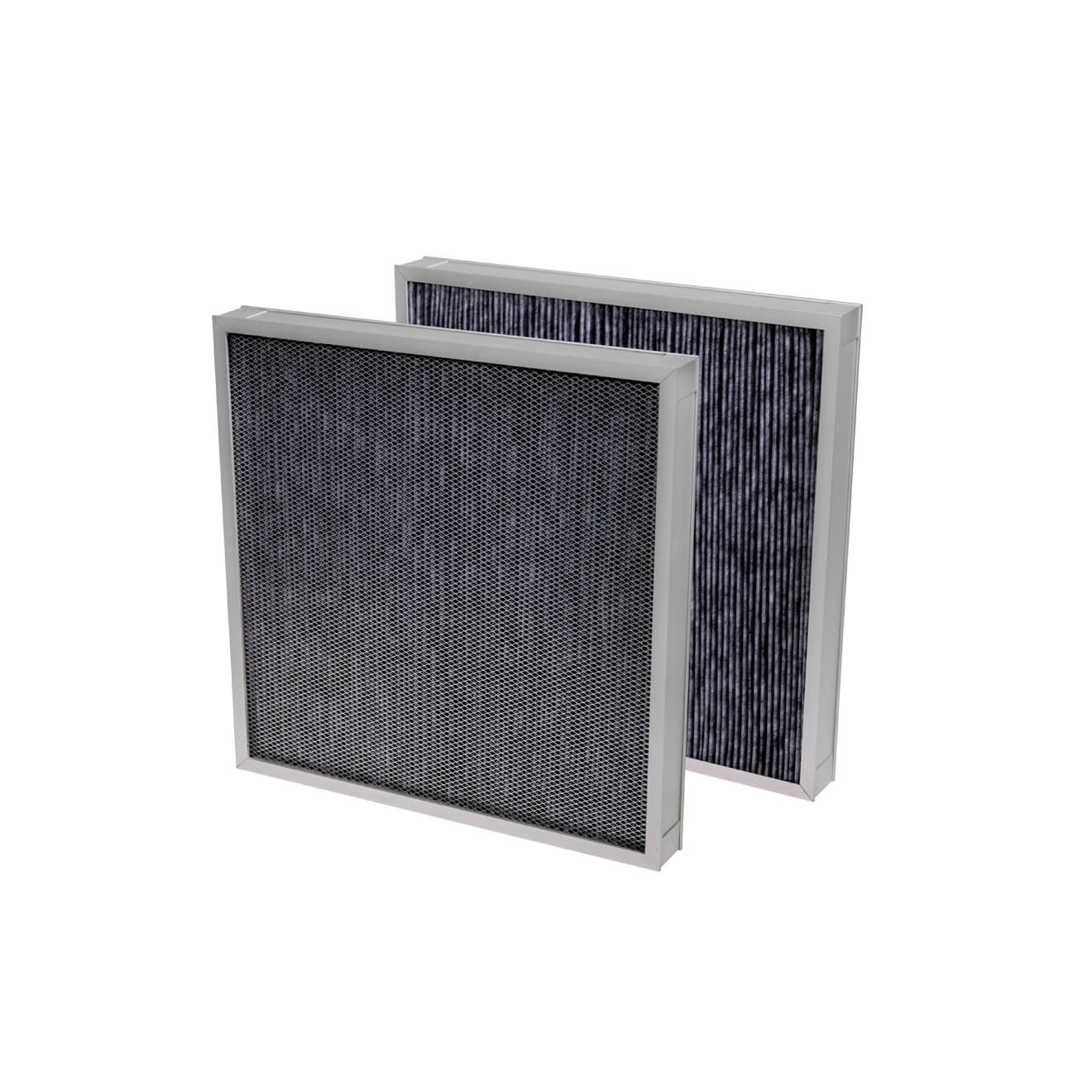

Fiberbed Mist Collector Charcoal Filters

Charcoal filters have been integrated into the Fiberbed Mist Collector, enhancing its ability to capture odor-causing compounds and improving air quality for asphalt facilities. This upgrade demonstrates Astec’s commitment to providing innovative, environmentally focused solutions that benefit both customers and surrounding communities.

Downloads

Where to Buy

Find an Astec Contact Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

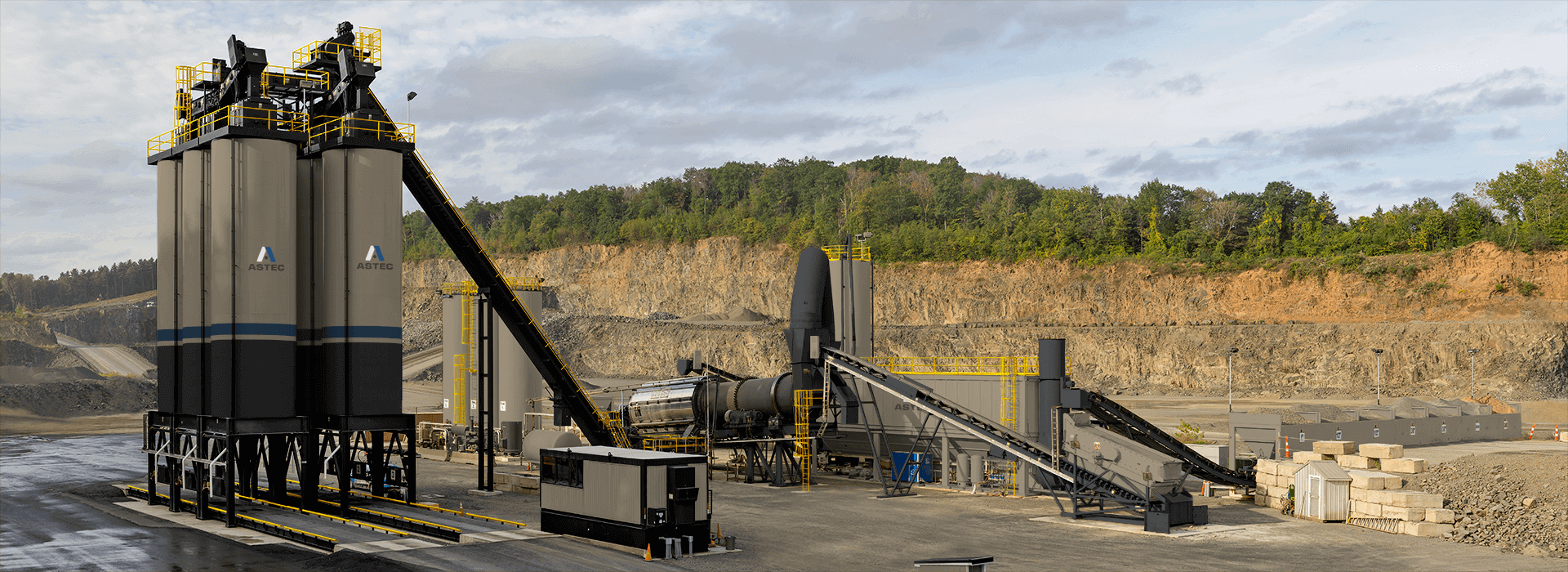

Asphalt Mixing

Astec produces a complete line of asphalt mixing plants, and its range of capacities and features gives you the choices and flexibility to create your optimum plant.

Learn More about Asphalt Mixing