Heatec HC & HCS Heaters

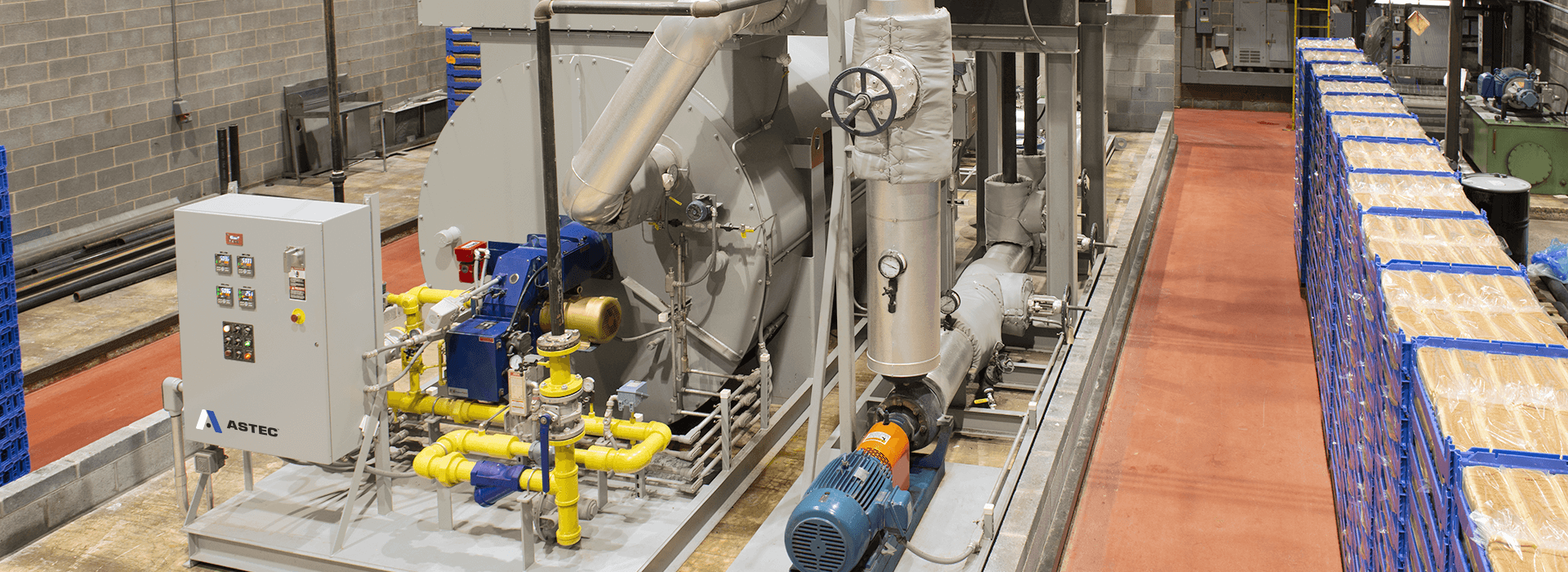

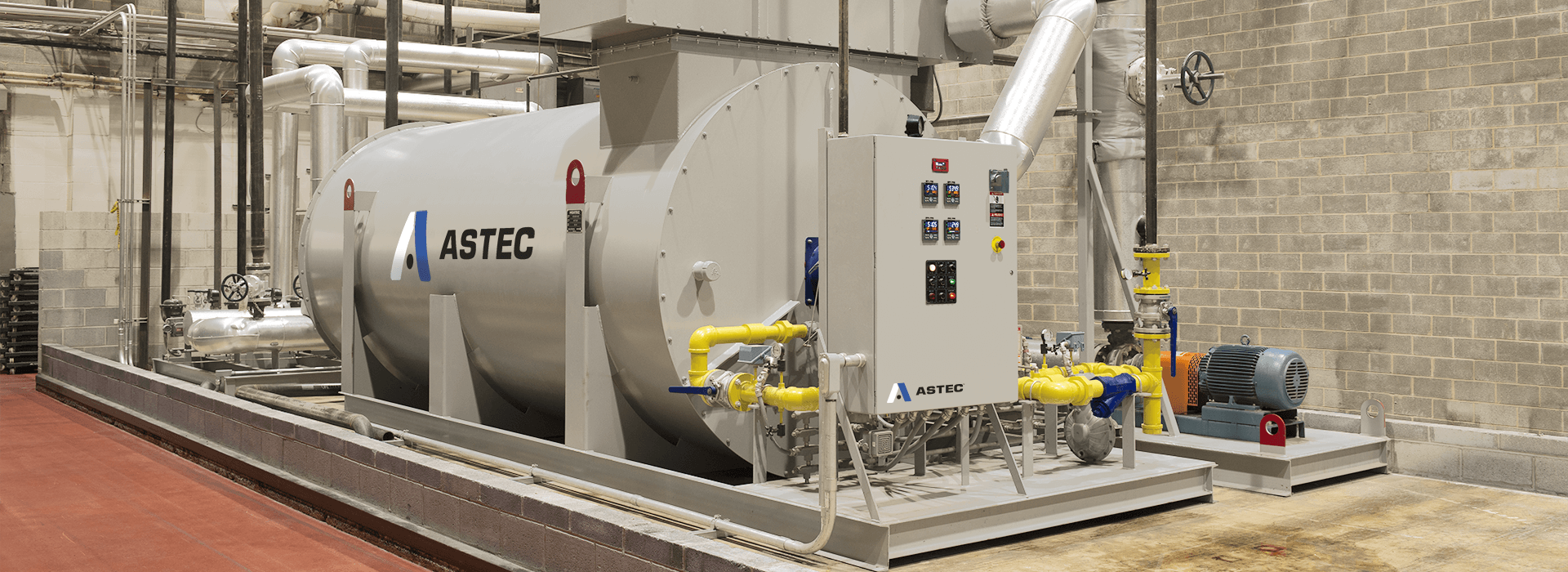

Heatec HC & HCS heaters are direct fired heaters designed around a helical coil. These heaters can be used for a variety of applications. Their popularity comes from their simplicity, efficiency, low maintenance and relatively low cost.

Overview

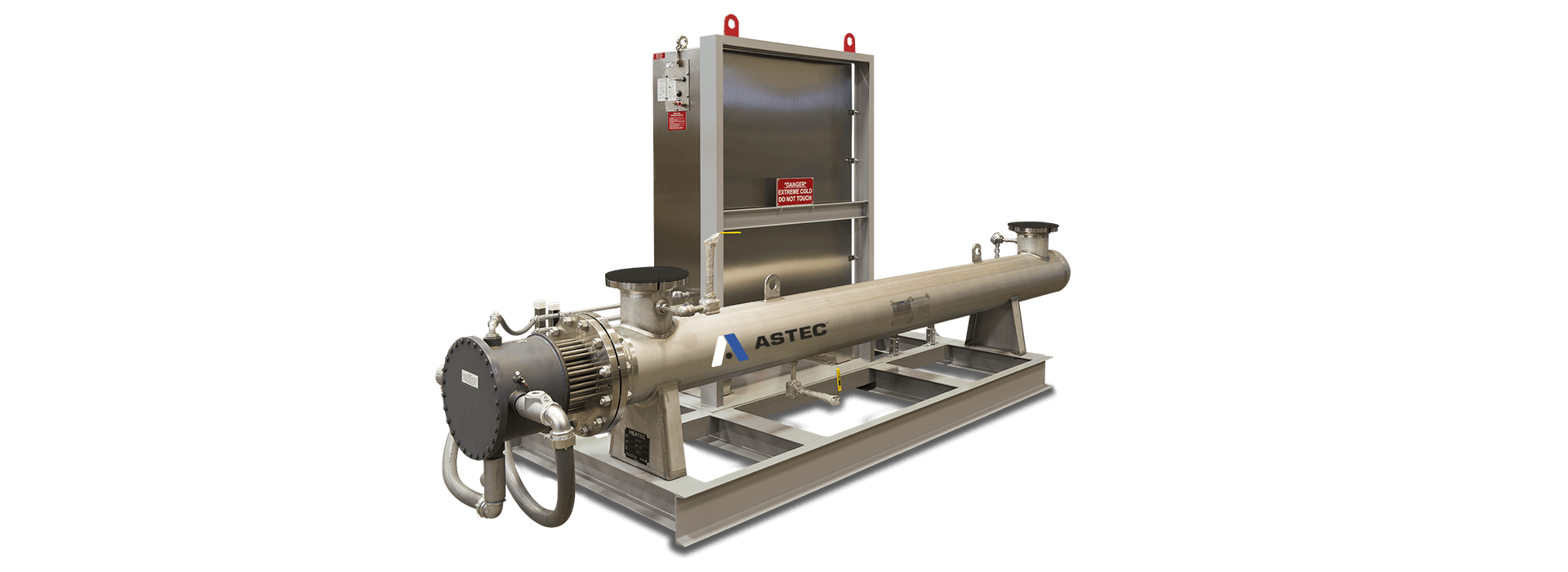

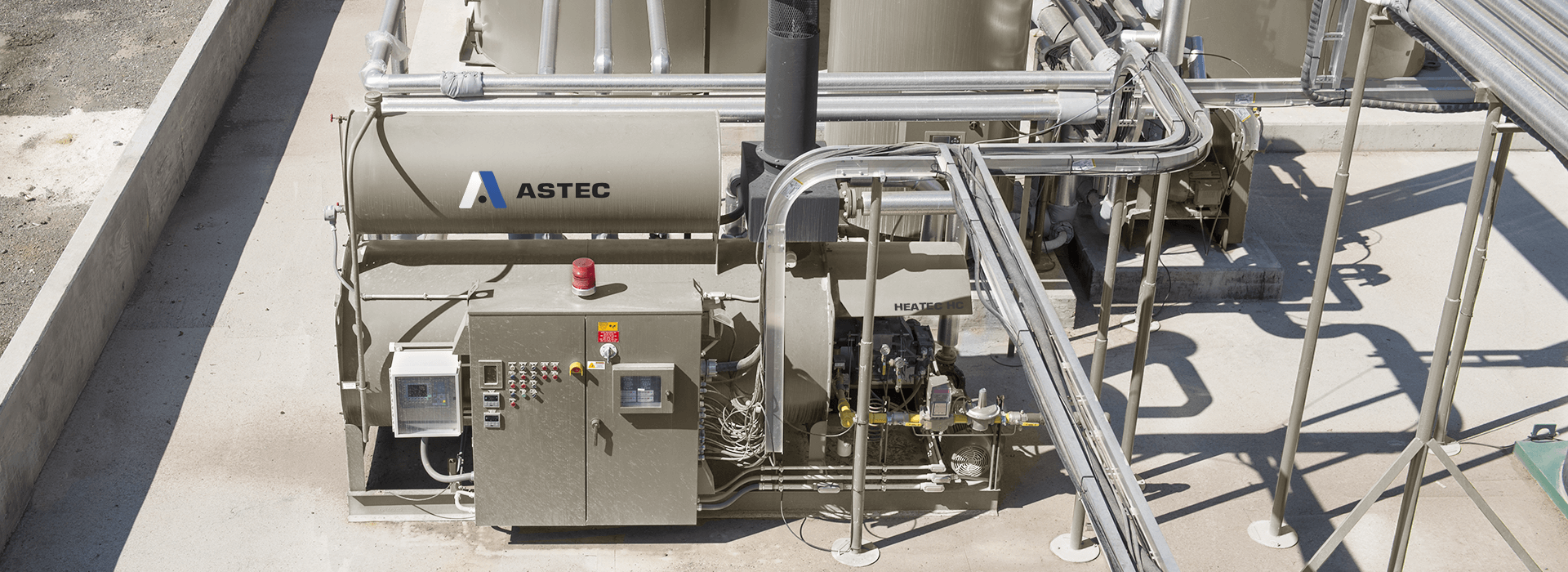

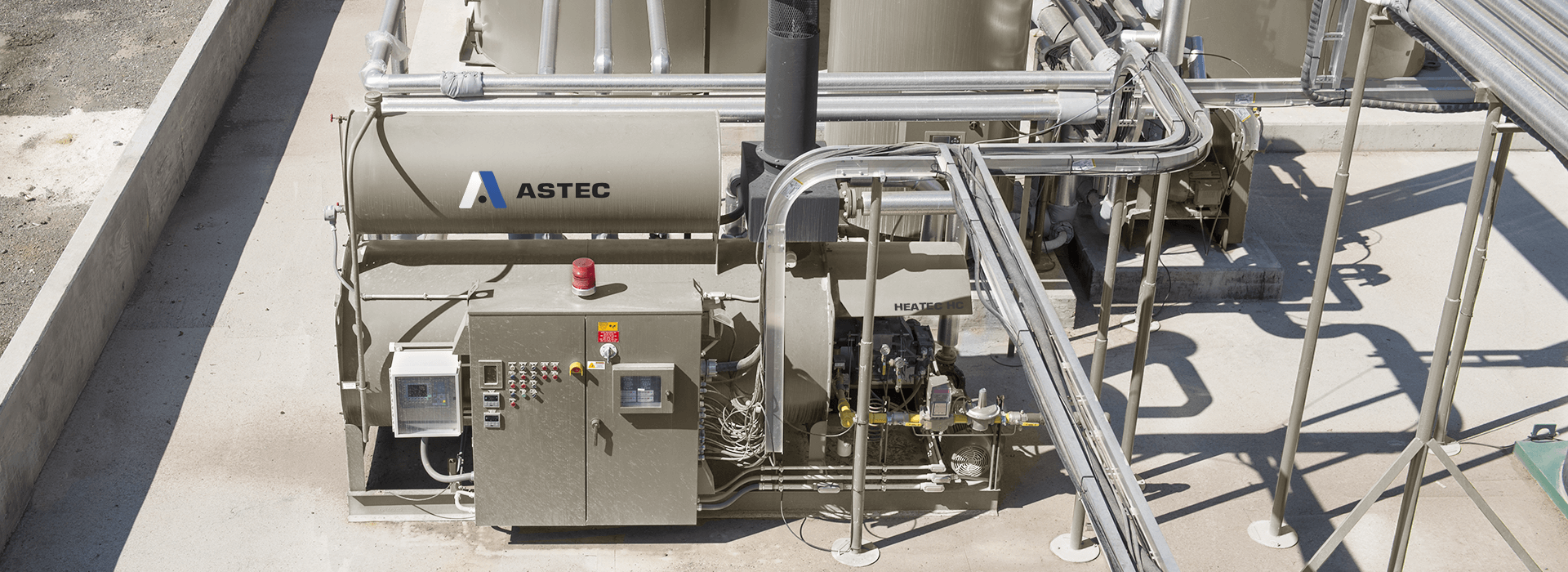

Heatec HC & HCS heaters are direct fired heaters designed around a helical coil. Our coil meets ASME code. These heaters were originally designed to be used at asphalt plants for mixing road grade asphalt, but because of their versatility they can be found in a number of different facilities for a variety of applications. Their popularity comes from their simplicity, efficiency, low maintenance and relatively low cost. Heat transfer mediums used can be thermal fluid (hot oil), glycol mixtures, or gases. They are also used as process heaters, directly heating the process fluid or gas.

Models and Outputs

Nine standard models are available. Rated thermal outputs range from 0.7 to 4 million Btu per hour. All can be customized to meet your specific needs.

Two Basic Configurations

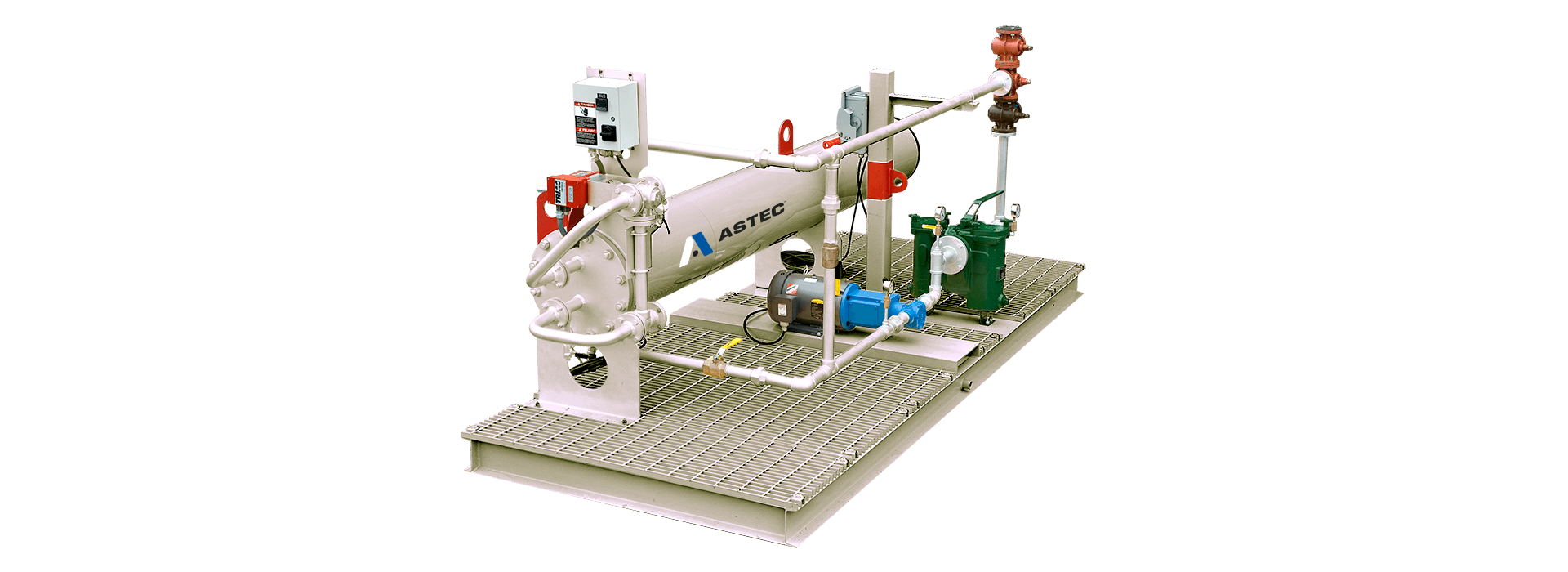

Heatec helical coil heaters are available in two basic configurations: HC and HCS. The HC configuration has a manifold that enables the heater to operate with multiple thermal fluid circuits.

Features

Heatec HC & HCS Efficiency

A hallmark of our helical coil heater is high thermal efficiency. Thermal efficiencies of our standard heaters range up to 85 percent LHV, depending upon fluid outlet temperature and fuel. Thermal efficiency is the total amount of heat produced by the burner versus the portion actually transferred to thermal fluid flowing through the coil. Thus, in our heaters, up to 85 percent of the total heat is transferred to the thermal fluid. Increasing efficiency reduces fuel usage. Adding a STACKPACK™ heat exchanger (economizer) boosts thermal efficiency another 5 percent. It makes our current heater super-efficient. That extra percentage reduces monthly fuel usage by 261 gallons of No. 2 fuel oil or 345 therms of natural gas. The Stackpack heat exchanger usually pays for itself in a year or less.

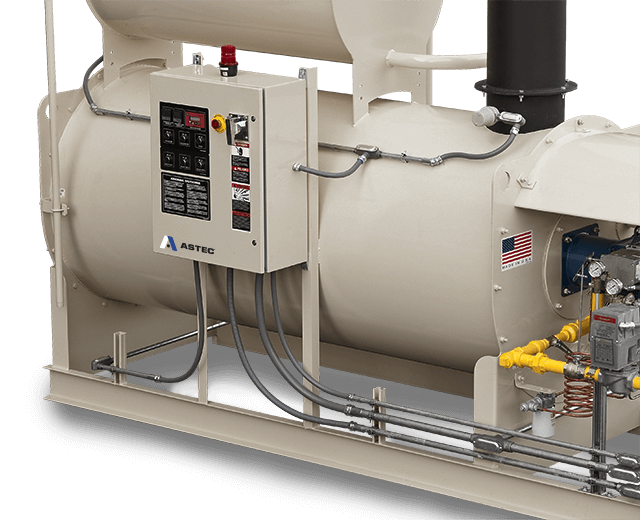

Heatec HC & HCS Heater Controls

Heater controls automatically maintain the operating temperature set by the operator. Accuracy is within a half percent of set temperature. Numerous safety features ensure heater operation is always within prescribed limits. Heaters shut down automatically if an abnormal operating condition occurs. Switches and sensors in a limit circuit ensure normal operation. They monitor burner flame, thermal fluid temperature, exhaust gas temperature, flow of thermal fluid, and combustion air pressure. Main controls are in a UL approved NEMA-4 panel

Burner controls Burner management controls provide proper and safe operation of the burner. They include a display, burner control, programmer, annunciator and flame scanner. The burner control uses a microprocessor for its management functions. The processor provides the proper burner sequencing, ignition and flame monitoring protection. The controls provide important messages about the operating status of the heater. If there is an alarm condition, a message will appear on the display.

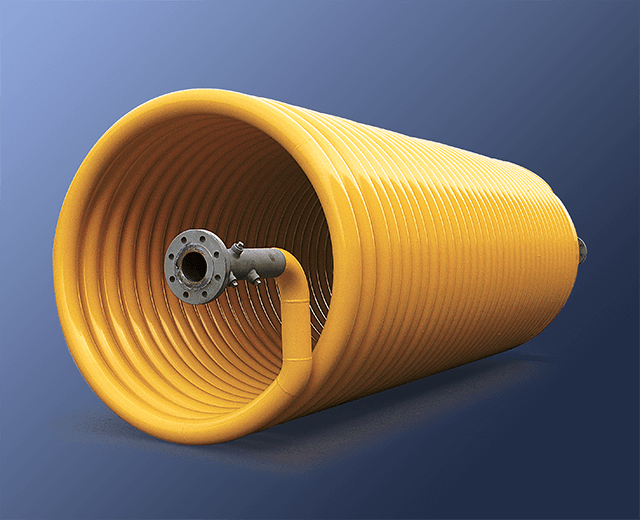

Heatec HC & HCS Helical Coil

Helical coils in our heaters set us apart from others that produce helical coil heaters for the HMA industry. We are the only heater manufacturer that builds all coils to ASME code. Certification is optional. Coils in HCS heaters have a three year warranty. Coils in HC heaters have a five year warranty.

Downloads

Where to Buy

Find an Astec Contact Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Agriculture & Fertilizer

Today's sophisticated systems help ensure both safe and efficient production both in the field or in the production of fertilizers.

Learn More about Agriculture & Fertilizer

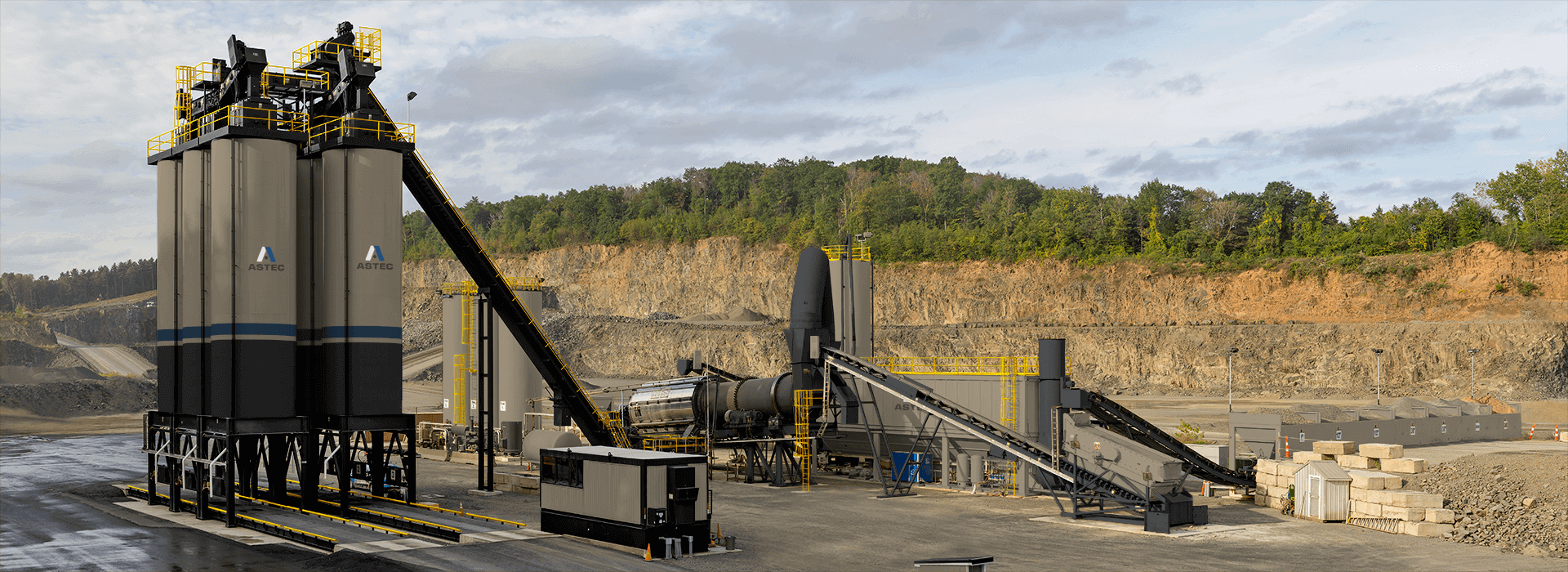

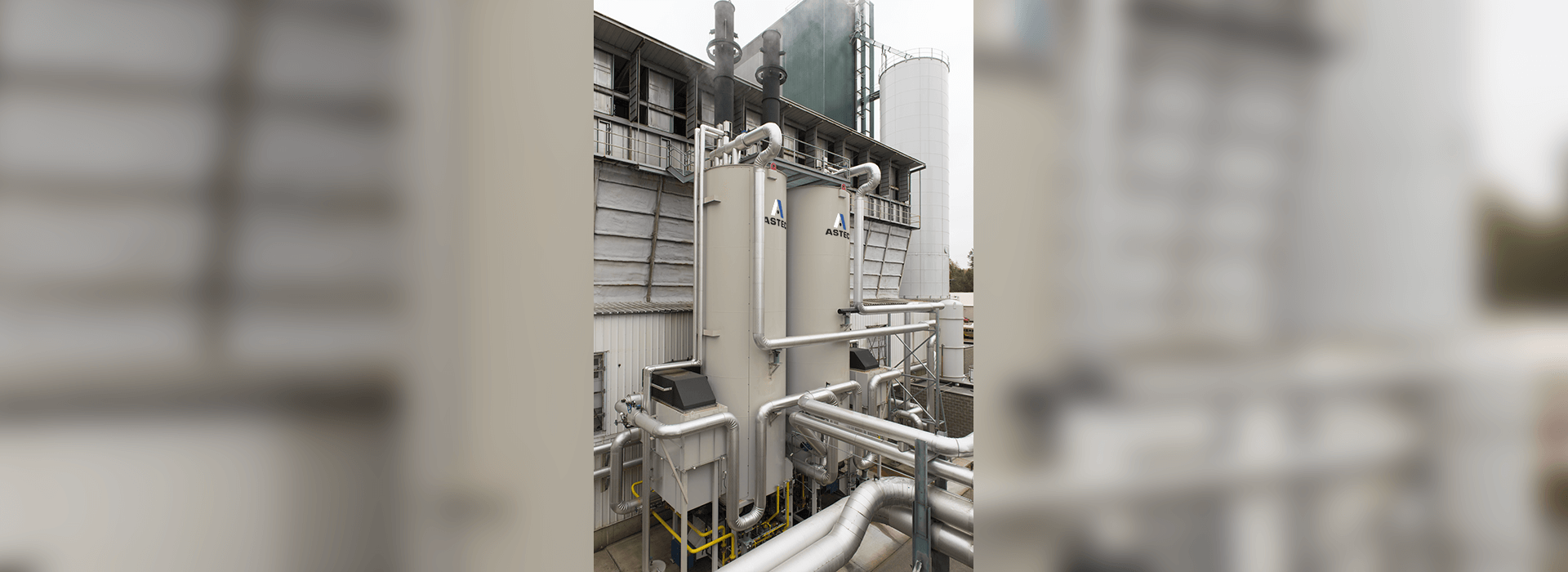

Asphalt Mixing

Astec produces a complete line of asphalt mixing plants, and its range of capacities and features gives you the choices and flexibility to create your optimum plant.

Learn More about Asphalt Mixing

Chemical

Chemical plants convert oil, natural gas, air, water, metals, and minerals into chemical products.

Learn More about Chemical

Crude Oil & Natural Gas Processing

Refining and processing crude oil and natural gas require highly reliable and efficient heating systems and services.

Learn More about Crude Oil & Natural Gas Processing

Food & Beverage Production

Astec has extensive experience with supplying systems for large-scale food and beverage production.

Learn More about Food & Beverage Production

Paints, Resins & Adhesives

Astec has a long history producing trustworthy and efficient thermal systems that can be used in the production of paints, resins, and adhesives.

Learn More about Paints, Resins & Adhesives

Petrochemical

The petrochemical industry relies heavily on various thermal processes and heat-controlled methods to produce its vital materials.

Learn More about Petrochemical

Plastics & Thermoplastics

The plastics industry relies on industrial heaters to mold, melt, mix, and prep plastics.

Learn More about Plastics & Thermoplastics

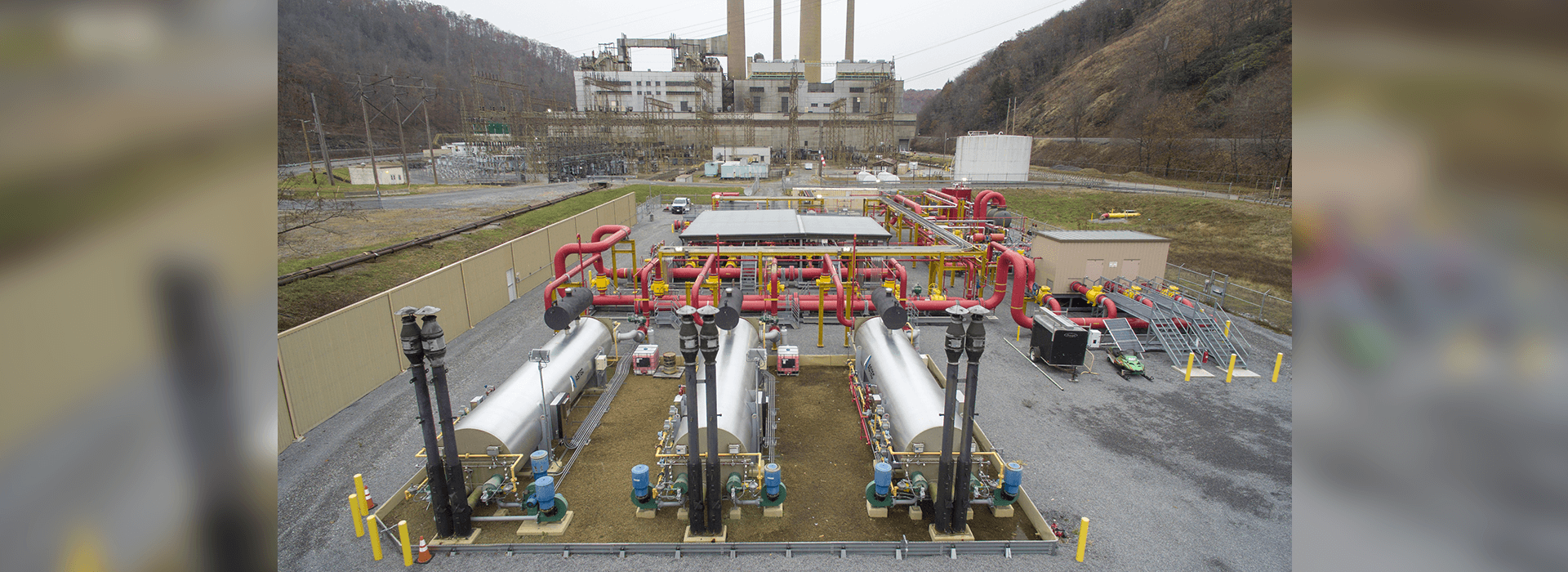

Power Generation

Astec serves the power and electricity generation industry with a number of products such as thermal fluid heaters, process heaters, heat economizers, and expansion tanks and pump skids.

Learn More about Power Generation

Roofing & Construction Products

Astec has an extensive background in supplying equipment to the asphalt/roofing industry heating such as liquid asphalt storage as well as experience with all types of thermal systems.

Learn More about Roofing & Construction Products

Textiles & Packaging

Heating and thermal process are indispensable in the production of textiles and packaging.

Learn More about Textiles & Packaging