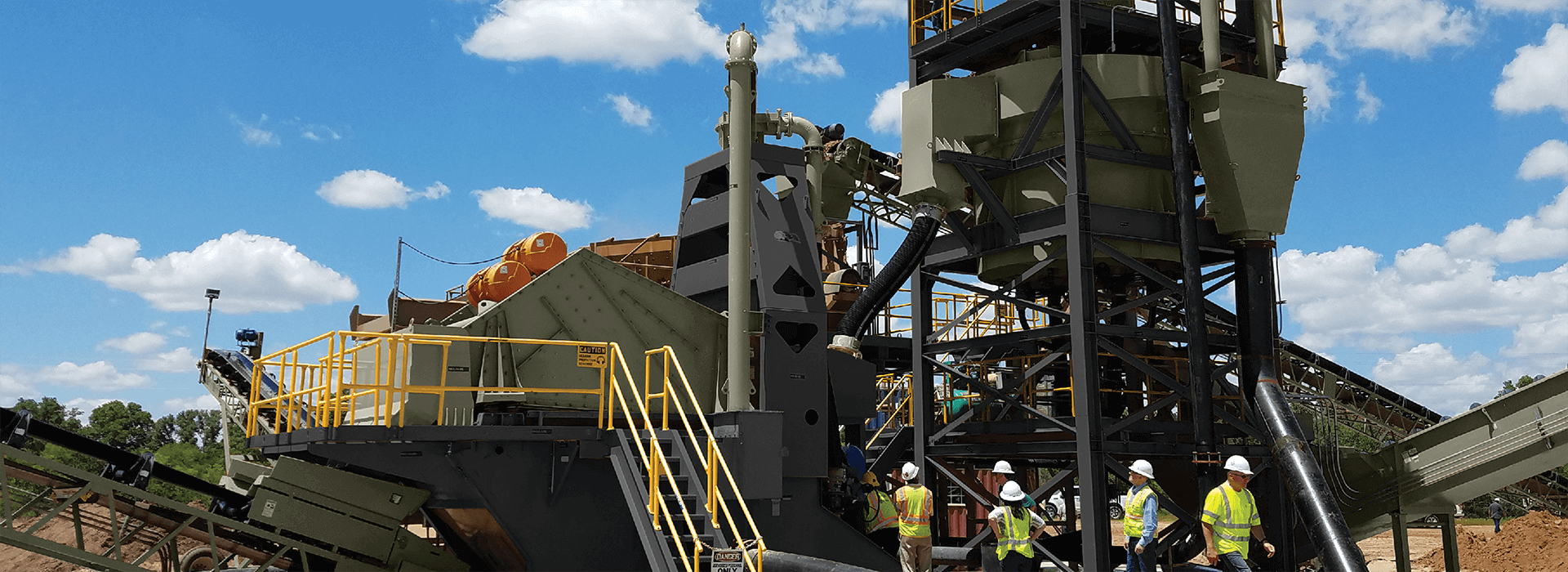

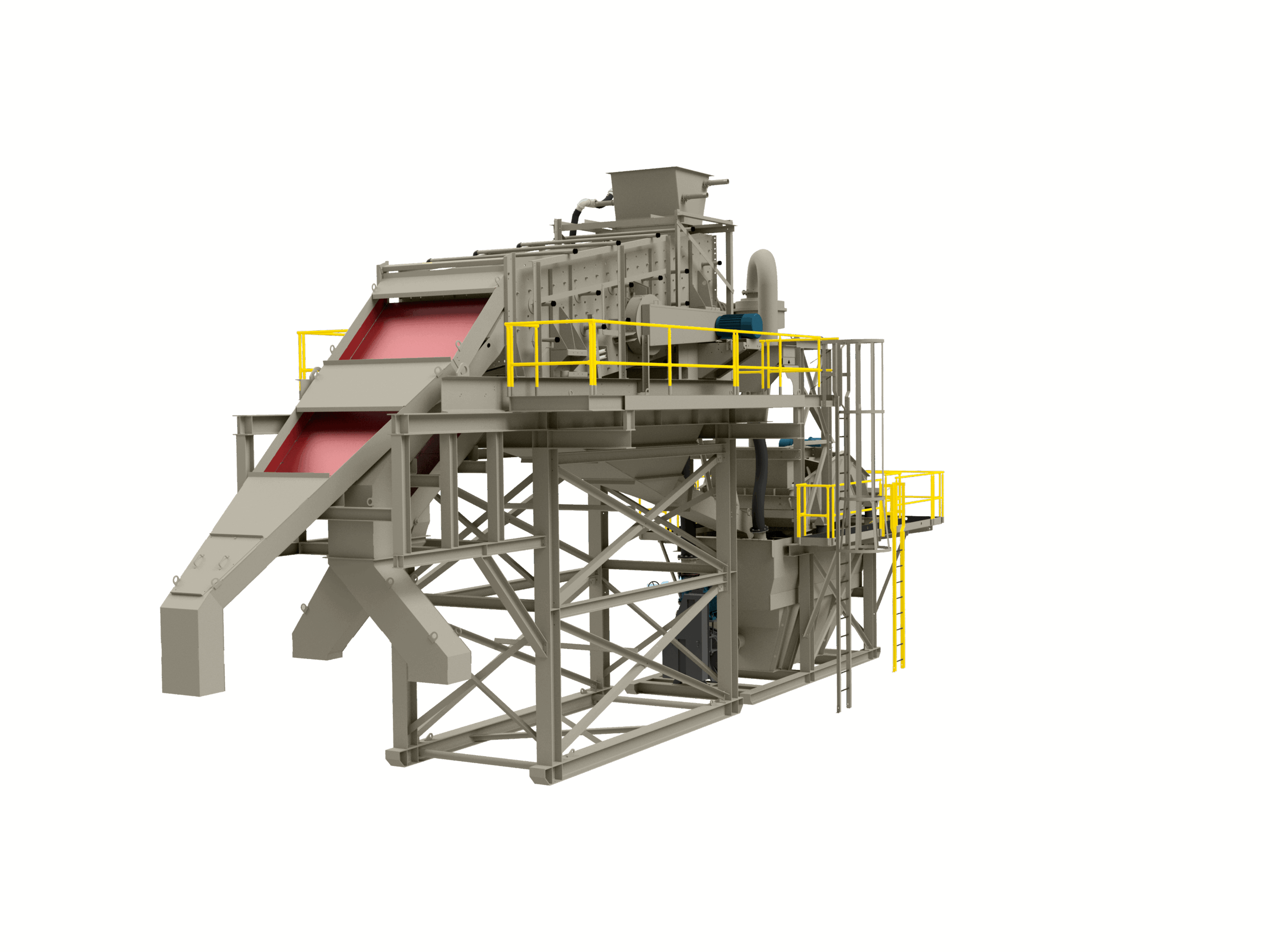

Modular Screening/Washing Plants

Efficiently process aggregate material wherever opportunities exist with our modular Series 1800 screening and washing plants.

Overview

Efficiently process aggregate material wherever opportunities exist with our modular Series 1800 screening and washing plants.

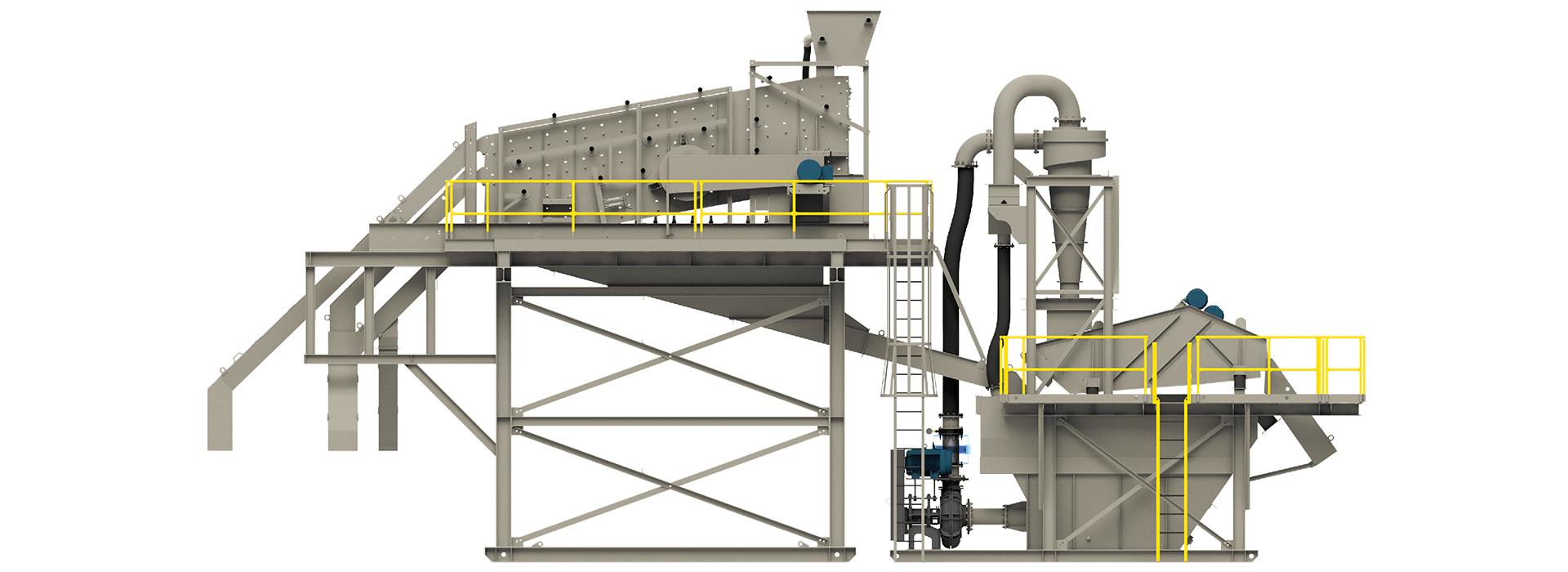

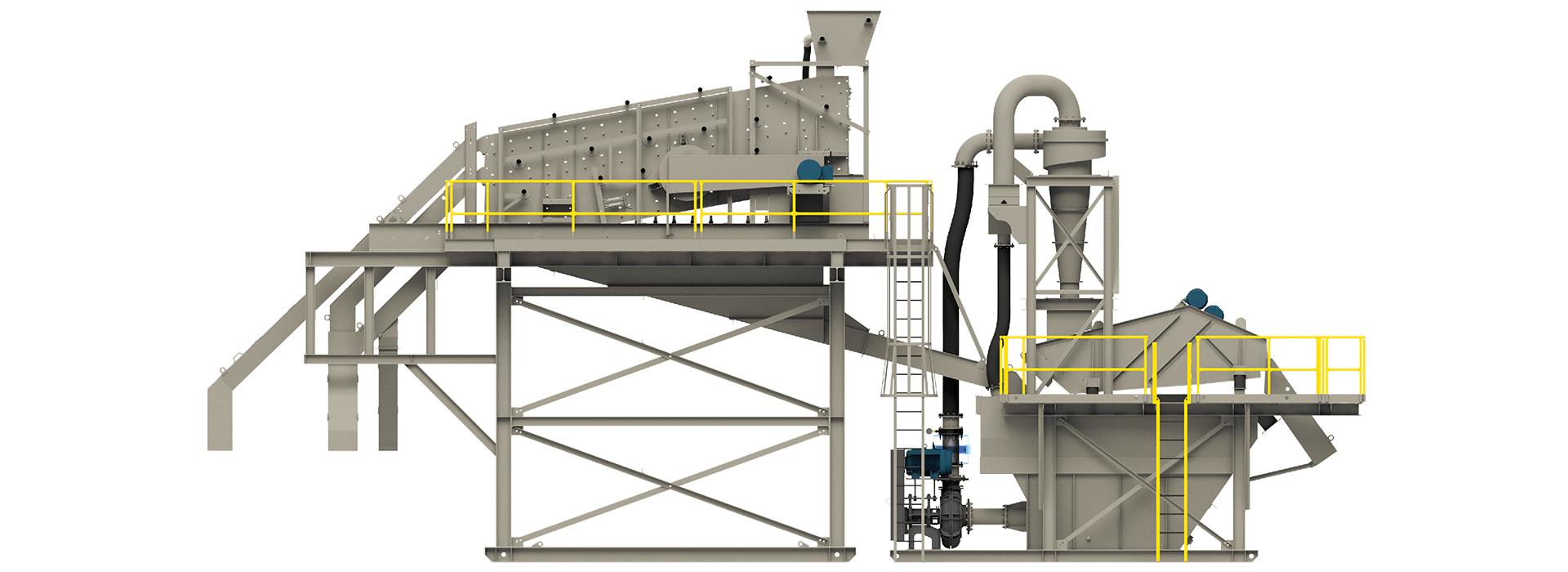

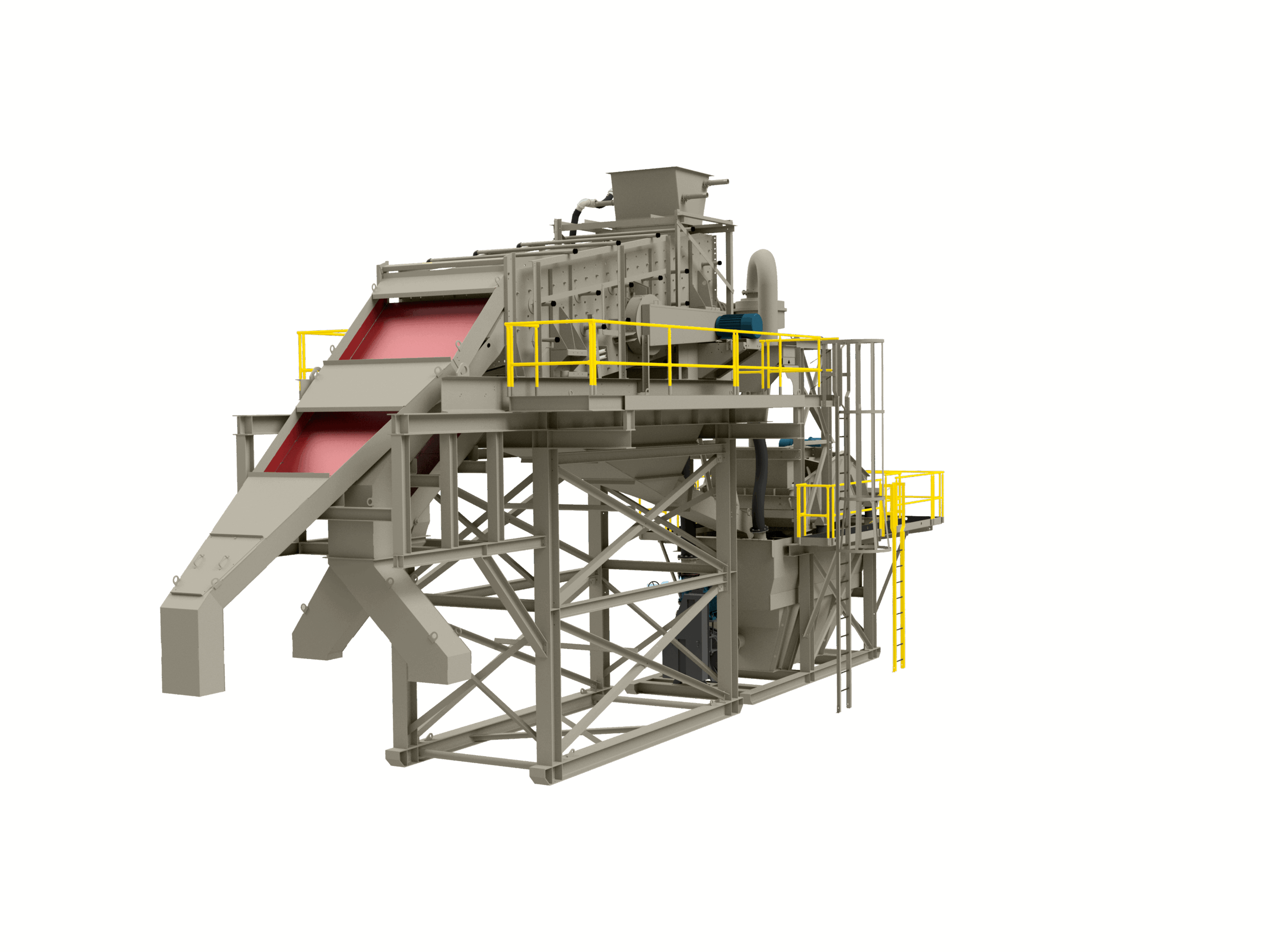

These plants offer our industry-leading fine material washer with an array of configurations — choose inclined or horizontal wet single- or triple-shaft screens with two or three decks all on one convenient structure.

Features

Plant Structure

- Plants are broken down for shipment

- Plants include fresh and wastewater systems (control valves, spray bars, manifolds, etc.)

- Screen overs chutes allow for positioning of three radial stackers to maximize stockpiling capacity

Plant Components

- Horizontal or incline screen

- Dewatering screensfrom 3’ x 8’ to 8’ x 16’

- Slurry pumps

- Cyclones

Downloads

Where to Buy

Find an Astec Dealer Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Aggregates

There are two main classes of aggregates: natural and manufactured.

Learn More about Aggregates

Construction Aggregates

Construction aggregate is typically medium or coarse materials like granite, limestone or trap rock, sand, gravel, slag or recycled concrete.

Learn More about Construction Aggregates

Sand & Gravel

Aggregates, when gathered, may contain clays, silts and other deleterious material that needs to be processed out for commercial-grade products.

Learn More about Sand & Gravel