Peterson 3710E Horizontal Grinder

The 3710E horizontal grinder is designed for high-volume producers who require frequent moves among sites, but need industry leading productivity.

Feed Opening:

57.25" x 40" (145.4 x 102 cm)

Horsepower:

755 hp (563 kW)

Machine Weight:

78,000 lb (35380 kg)

Overview

The 3710E horizontal grinder is designed for high-volume producers who require frequent moves among sites, but need industry leading productivity. The 3710E features 4,070 square-inches of screening area and a 20 bit rotor to process even the hardest organic materials. The four-grate sizing system can be easily reconfigured to make just the product your customers are looking for.

Powered by a Tier IV Caterpillar C18 755 hp (563 kW) engine, the 3710E has the power to tackle the hardest jobs, and is easily maneuvered with its remote controlled track system.

Astec’s optional Peterson transportation dolly is designed to be used with the Peterson 3710E or 5710E horizontal grinder and is an ideal solution for grinding operations that have frequent moves between jobs.

Features

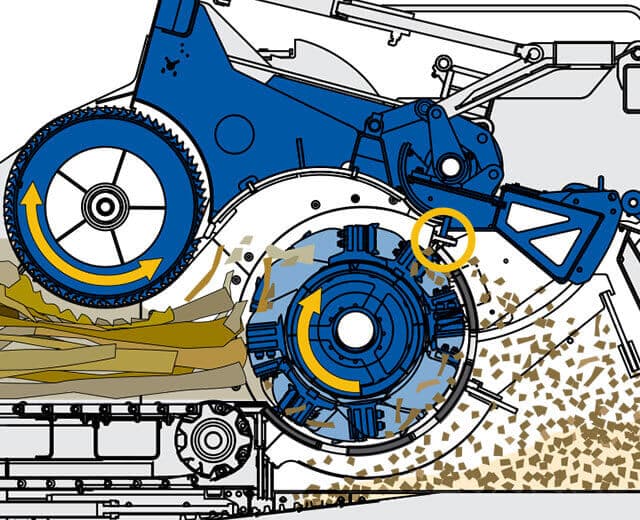

3-Stage Grinding Process

The powerful up-turn 3-stage grinding process provides better fracturing of material and a more consistent product, giving you just the product your buyers want.

Impact Release System Protects Your Investment

The air bags on the patented Astec Impact Release System provide uniform grinding and protection from contaminated feedstock, a feature unique to Peterson grinders.

The Second Line of Defense: the Impact Cushion System

Urethane cushions and shear pins help protect the mill from catastrophic damage in the event of a severe impact from contaminants in the feedstock.

Downloads

Specifications

All specifications subject to change without notice.

Where to Buy

Find an Astec Dealer Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Biomass

Biomass is an energy source derived from renewable and sustainable organic materials to create electricity or other forms of power.

Learn More about Biomass

Land Clearing

Land clearing generally consists of trees, limbs & roots cleared from forested or partially forested land that will be used for a new purpose including farming, commercial development or right-of-ways

Learn More about Land Clearing

Mulch

Organic mulch is a product that can decompose, providing nutrients to the soil over time.

Learn More about Mulch

Organic Recycling

Green waste recycling turns biodegradable materials into compost, keeping them out of landfills and enriching gardens.

Learn More about Organic Recycling

Wood Waste Recycling

Wood waste is the second largest category of construction and demolition (C&D) debris, and accounts for 10% of material added to landfills annually.

Learn More about Wood Waste Recycling