Screening Innovation: The Path to Operational Excellence with Astec

By partnering with Astec and implementing the new Vari-Frequency screen, Perkins Cinders unlocked a major throughput increase in its cinder production.

Highlights

Perkins Cinders |

|

|---|---|

| Location: Northern Arizona, USA |

|

| Application: Cinder Screening |

|

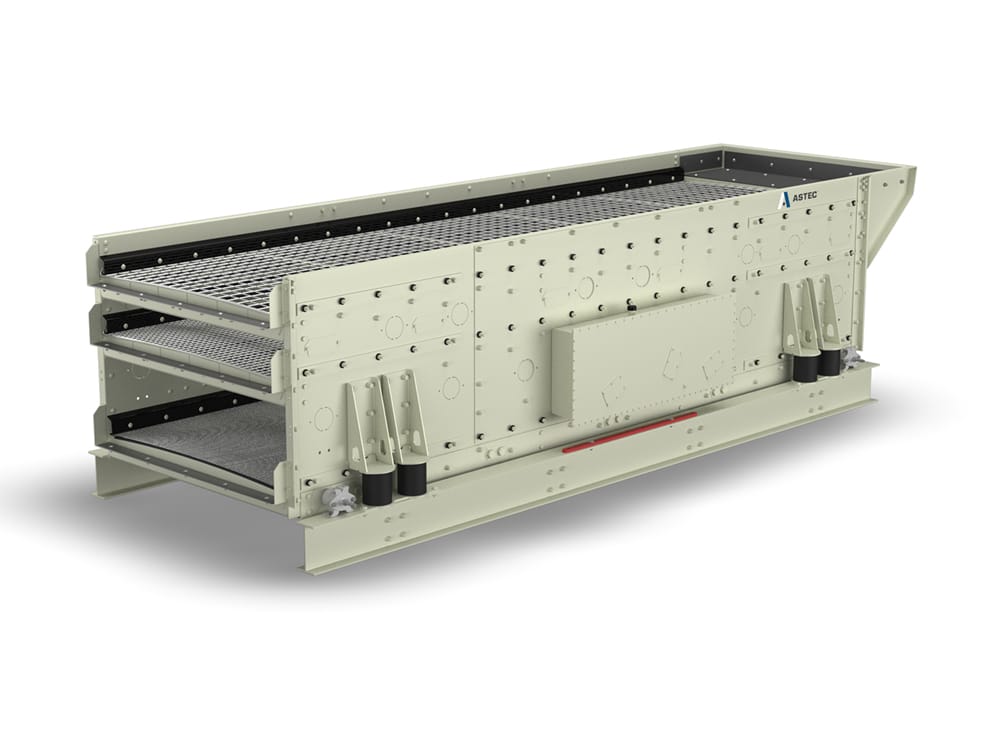

| Equipment: Astec Vari-Frequency Screen |

|

| Time in Operation: Since March 2024 |

|

When Perkins Cinders set out to increase production efficiency across its operations, the goal was clear: find equipment that could deliver measurable performance gains without compromising safety or reliability. For Josh Tatum, a long-time champion of smart, data-driven investment, that meant evaluating every piece of the process—including screening. By partnering with Astec and implementing the new Vari-Frequency screen, Perkins Cinders unlocked a major throughput increase in its cinder production, reinforcing Josh’s belief in innovation backed by trusted relationships.

The Challenge

Cinders can be tricky to screen because they hold onto moisture and are relatively lightweight. These traits make it harder for the material to move smoothly across the screen, often leading to blinding. This slows down production and increases the time spent on cleaning and maintenance. While premium screen media can help reduce these issues, they often lack the durability and productivity gains that make a higher investment truly worthwhile.

The Customer

For Josh Tatum, growth has never been about standing still. As Operations Manager at Perkins Cinders, Josh has built his career around finding smarter, more efficient ways to run the business—and that means investing in the right equipment, even when it requires pushing boundaries.

The relationship between Perkins Cinders and Astec began at a pivotal moment of transformation. After the company acquired a neighboring operation, Josh recognized that their legacy equipment couldn’t keep up with the scale and complexity of the work ahead. “We picked up a rather large job,” he recalls, “and we knew we needed something better.”

That something better turned out to be a Telsmith® crushing plant—an Astec legacy product brand. It wasn’t the cheapest option on the table, and convincing leadership required more than gut instinct. Josh came armed with data, highlighting the downtime, labor, and safety costs associated with less advanced equipment. “The plant I wanted to buy, I could adjust on the fly—while crushing or not. The other plant required constant stops, extra manpower, and had real safety limitations,” he explains.

That decision marked the beginning of a relationship built on results and trust. “I really liked Telsmith support. Their service was great.”

Over time, Josh’s pursuit of optimized performance led to more opportunities to work with Astec. A portable job opened the door to the FT4250 mobile impact crusher—another win. Then came a need for a track-mounted screen. Josh did his homework, evaluated competitors, and once again chose Astec, this time purchasing the GT165. “Immediately the results we got in the field were significantly different—in a positive way. That built a little more momentum, a little more trust.”

That trust carried into one of their biggest equipment investments yet: a large plant including a 3055 jaw, K400 cone, 8×20 screen, and conveyor components. Josh brought his usual rigor to the decision, consulting with both dealers and Astec directly. “If I have good relationships with people, I’m going to bring them to the table,” he says.

For Josh, it’s never just about buying machines. It’s about partnering with people who understand his goals and are willing to support his vision. “At the end of the day, maybe Astec isn’t always the solution,” he says. “But they’ve earned a seat at the table every time.”

The Solution

Josh’s high standards for equipment performance and his track record of pushing for better solutions made him a natural fit to field test one of the first Vari-Frequency screens. Developed to meet the demands of high-volume producers, the screen delivered a fresh approach to material handling—bringing new flexibility and performance to Perkins Cinders’ screening process.

Astec’s Vari-Frequency screen brings a new level of control to the screening process. With its ability to adapt in real time to changing material conditions, it helps operators maintain steady production and reduce disruptions. For Perkins Cinders, this meant fewer slowdowns, less manual cleaning, and a smoother path to meeting production goals.

“It almost works too well,” Tatum explained. “In the past, we’d sometimes run traditional components for an hour and have to shut the machine down for 30 minutes to clean. In a 10-hour day, you’re losing hours of production. That drives your cost up and can even push you out of the market.”

At the heart of the screen’s performance is its novel agitation system. Unlike conventional designs, the Vari-Frequency screen uses reverberating cables to generate powerful G-force spikes across the bottom deck. This dynamic motion keeps material moving, minimizes blinding, and drastically reduces the need for manual intervention. For operations like Perkins Cinders—where uptime is everything—this technology has proven to be a game changer, allowing crews to maintain consistent production rates without the frequent shutdowns that once stalled progress.

The Results

The difference in performance was immediate and dramatic:

Downtime for screen cleaning was virtually eliminated, dropping from hours per day to about 30 minutes per week—and in some weeks, none at all.

Throughput increased significantly, with production volumes rising by as much as 45% in certain configurations.

Cost per ton dropped, thanks to increased efficiency and lower operating costs.

“In our application, we’re hands down running faster than we ever did with conventional screens,” said Tatum. “It’s not even arguable.”

Operations Manager, Damon Eggert reinforced those results: “Before installing the new screen deck, our throughput was approximately 70 tons per hour of cinder. Since its introduction, we have increased to around 120 tons per hour. The quality of the material has improved by 100%, and the time required for screen cleaning has been reduced to a minimum. Additionally, wear on the screen deck parts has been minimal in this cinder application. Overall, the screen deck has made our operations easier and more profitable.”

Tatum described a specific scenario where they pushed the screen to its limit by running fine material exclusively over the bottom deck. “We were screening a 3/8-minus and a 3/16-minus product and the bottom deck handled it so efficiently, we actually didn’t get the carryover we needed. That’s how good it is.”

The increased efficiency has a direct impact on operating economics. Tatum explained that previously their input might have been 70 tons/hour. Now, with the new screen, that input can reach 120 tons/hour—dramatically improving the cost-per-ton equation.

Closing Insights

For Tatum, the benefits go beyond numbers. The Vari-Frequency screen represents a long-awaited solution to problems that had plagued their operations for decades. “When we were testing it, we had a hard time getting it to fail,” he said.

He believes the real value comes from how the screen combines versatility, efficiency, and cost control. “I would tell other producers: what if I told you I have a screen that changes itself several times a day in just five minutes? Everyone would want to know more.”

Perkins Cinders is now running joint ventures with nearby producers who are still struggling with conventional equipment. Tatum sees it as a clear competitive advantage and a testament to what’s possible when innovation is paired with real-world input.

“The plant I wanted to buy, I could adjust on the fly—while crushing or not. The other plant required constant stops, extra manpower, and had real safety limitations.”

Josh Tatum, Operations Manager, Perkins Cinders